Composite flame retardant cable material containing polycyclotriphosphazene-sulfone microspheres and preparation method thereof

A polycyclotriphosphazene, composite flame retardant technology, applied in the direction of insulated cables, cables, circuits, etc., can solve the problems of poor compatibility, reduced material mechanical properties and processing properties, etc., to increase fluidity, improve mechanical properties and Processability, effect of high carbon residue rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

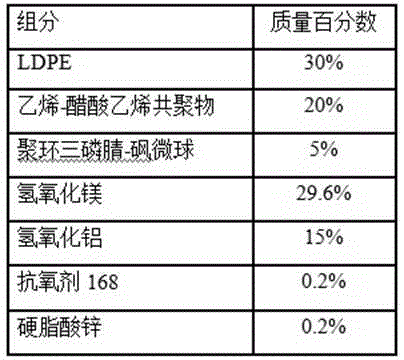

[0029] Embodiment one: each component and mass percentage thereof are as follows:

[0030]

[0031] The sheet or plate molding preparation method of the above-mentioned cable material, the preparation method steps are as follows:

[0032] According to the total weight of 200g, mix 60g LDPE, 40g ethylene-vinyl acetate copolymer, and 2g polycyclotriphosphazene-sulfone microspheres to obtain mixture A.

[0033] 66 g of magnesium hydroxide and 32 g of aluminum hydroxide were uniformly mixed to obtain mixture B.

[0034] Put the mixture A into the internal mixer for banburying, and set the material temperature to 160°C; after banburying for 5 minutes, add the mixture B to the internal mixer to continue the banburying, set the material temperature to 160°C, and banbury for 10 minutes to obtain a total of mixture.

[0035] Put the above-prepared blend into an open plastic mixer for kneading, the material temperature is set at 180°C, kneading is carried out 20 times, and the shee...

Embodiment 2

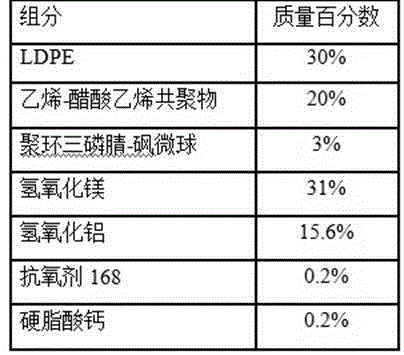

[0037] Embodiment two: contained component and mass percentage thereof are as follows:

[0038]

[0039] The preparation method of the above-mentioned cable material is the same as that of Example 1, and a performance testing test is carried out, and the results are shown in Table 1.

Embodiment 3

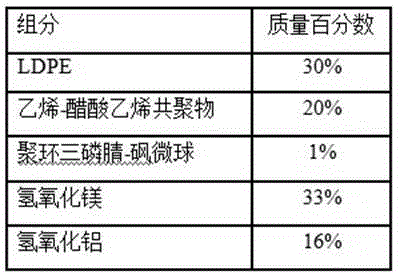

[0040] Embodiment three: contained component and mass percent thereof are as follows:

[0041]

[0042] The preparation method of the above-mentioned cable material is the same as that of Example 1, and a performance testing test is carried out, and the results are shown in Table 1.

[0043] Table 1:

[0044] .

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com