Environment-friendly water-based ink, environment-friendly high-strength damping corrugated paper box and manufacturing method of corrugated paper box

A water-based ink, corrugated box technology, applied in the direction of ink, chemical instruments and methods, rigid containers, etc., can solve the problems that affect the appearance and user experience, cannot meet the high-performance packaging, and the text is easy to blur or drop, so as to ensure the appearance and user experience, good cushioning effect, and improved mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] An environmentally friendly water-based ink, made of the following raw materials in parts by weight: 60-70 parts of water-soluble acrylic resin, 20-25 parts of water-based polyurethane resin, 7-10 parts of pigment, 12-15 parts of color paste, and 0.75 parts of defoaming agent ~0.85 parts, 0.4-0.55 parts of leveling agent, 3-5 parts of thickener, 0.7-0.9 parts of film-forming aid, 3-6 parts of tea polyphenols.

[0036] Preferably, 65 parts of water-soluble acrylic resin, 22.5 parts of water-based polyurethane resin, 8.4 parts of pigment, 13.5 parts of color paste, 0.8 part of defoamer, 0.47 part of leveling agent, 4.2 parts of thickener, 0.85 part of film-forming aid, 5.3 parts of tea polyphenols.

[0037] Preferably, the grade of the water-soluble acrylic resin is HR-2007.

[0038] Preferably, the following raw materials are also included in parts by weight: 5-8 parts of a mixture of nanometer zinc oxide and calcium oxide.

[0039] Preferably, the mass ratio of nano-z...

Embodiment 2

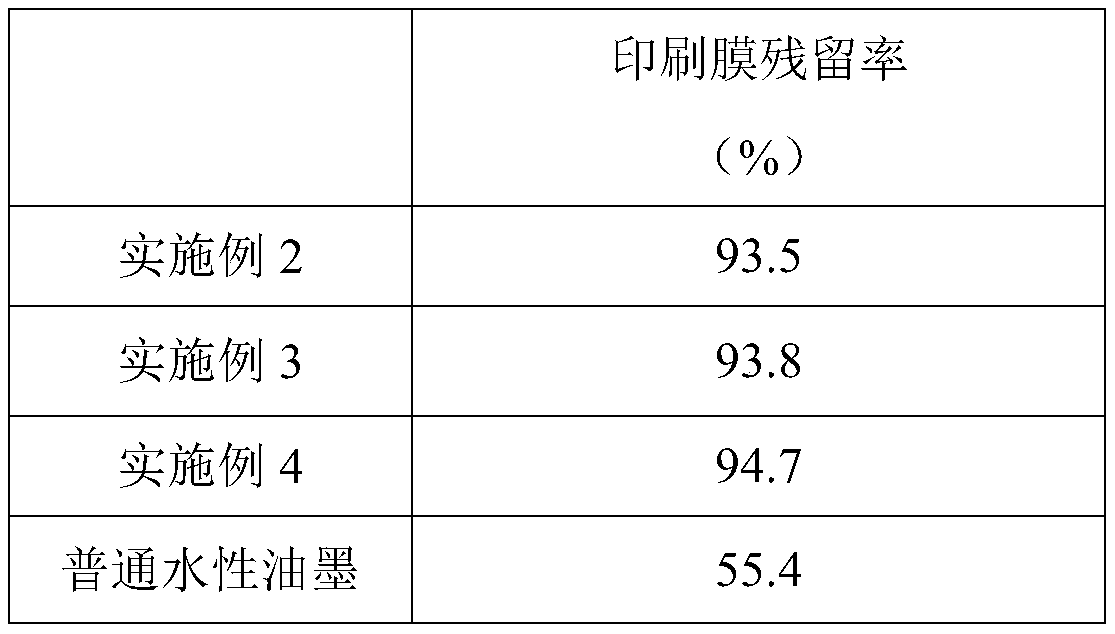

[0049] An environmentally friendly water-based ink, made of the following raw materials by weight: 60 parts of water-soluble acrylic resin, 20 parts of water-based polyurethane resin, 7 parts of pigment, 12 parts of color paste, 0.75 parts of defoaming agent, 0.4 part of leveling agent, 3 parts of thickener, 0.7 parts of film-forming aid, 3 parts of tea polyphenols.

[0050] In this embodiment, the grade of the water-soluble acrylic resin is HR-2007.

[0051] In this embodiment, the following raw materials are also included in parts by weight: 5 parts of a mixture of nanometer zinc oxide and calcium oxide.

[0052] In this embodiment, the mass ratio of nano zinc oxide to calcium oxide in the mixture of nano zinc oxide and calcium oxide is 1:0.7.

[0053] In this embodiment, the pigment is a water-based pigment.

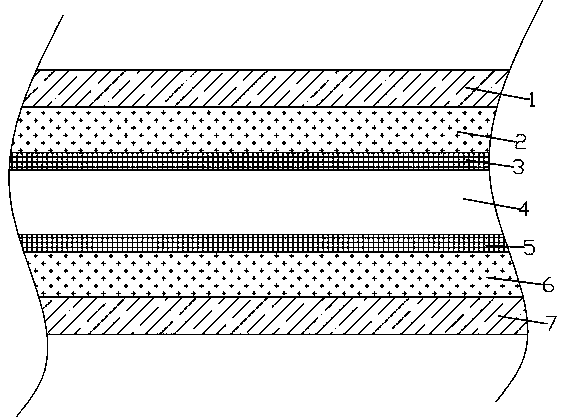

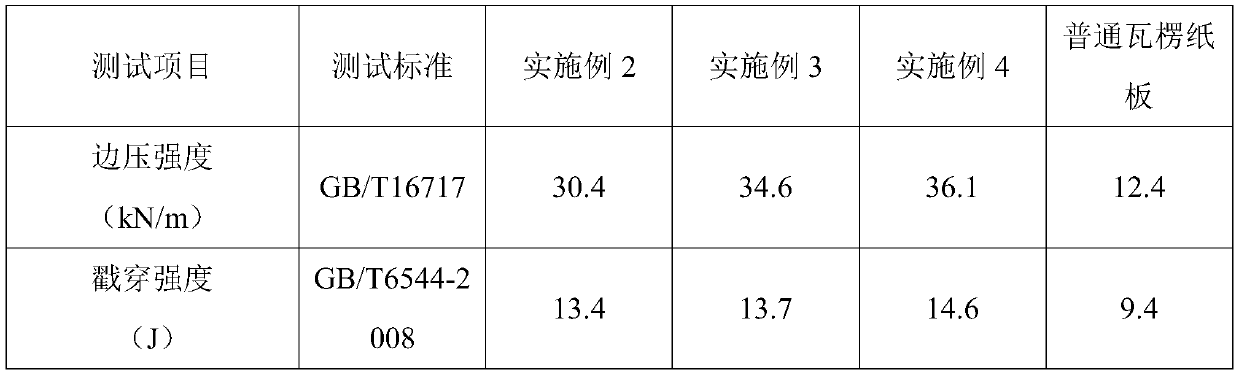

[0054] This embodiment also provides an environment-friendly high-strength shock-absorbing corrugated box, the surface of the environment-friendly high-strength sho...

Embodiment 3

[0062] An environmentally friendly water-based ink, made of raw materials comprising the following parts by weight: 70 parts of water-soluble acrylic resin, 25 parts of water-based polyurethane resin, 10 parts of pigment, 15 parts of color paste, 0.85 part of defoamer, 0.55 part of leveling agent, 5 parts of thickener, 0.9 parts of film-forming aid, 6 parts of tea polyphenols.

[0063] In this embodiment, the grade of the water-soluble acrylic resin is HR-2007.

[0064] In this embodiment, the following raw materials are also included in parts by weight: 8 parts of a mixture of nanometer zinc oxide and calcium oxide.

[0065] In this embodiment, the mass ratio of nano-zinc oxide and calcium oxide in the mixture of nano-zinc oxide and calcium oxide is 1:0.85.

[0066] In this embodiment, the pigment is a water-based pigment.

[0067] This embodiment also provides an environment-friendly high-strength shock-absorbing corrugated box, the surface of the environment-friendly high...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com