Halogen-free nitrogen-phosphorus complex intumescent flame retardant and preparation method thereof

An intumescent flame retardant, nitrogen and phosphorus compounding technology, applied in the field of flame retardants, can solve problems such as a large number of toxic and harmful substances, life-threatening, and achieve cost reduction, high carbon residue rate, and good chemical stability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] A kind of halogen-free nitrogen-phosphorus composite expansion type flame retardant, it is made by the raw material of following weight (kg): ammonium polyphosphate 40, melamine 25, polypentylthritol 15, urate 7, aluminum hydroxide 5. Zinc borate 0.4, Ionic surfactant 2.

[0023] The preparation method of the described halogen-free nitrogen and phosphorus composite intumescent flame retardant comprises the following steps:

[0024] According to the proportion, the raw materials ammonium polyphosphate, melamine, polypentyl glycolate, and urate are added to the reactor, and the temperature of the reactor is controlled by controlling the speed of the mixer in the reactor to increase slowly at 10°C / min, and keep at 100°C for 15 minutes, and pass Slowly add inorganic additives and zinc borate from the feeding port, slowly add ionic surfactant after 10 minutes, stop the reaction and discharge in 10 minutes.

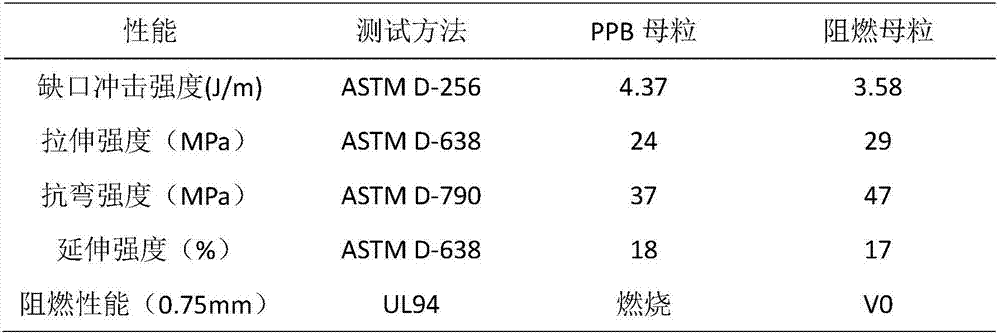

[0025] Taking this example as the raw material to prepare the copo...

Embodiment 2

[0028] A kind of halogen-free nitrogen-phosphorus composite intumescent flame retardant, it is made by the raw material of following weight (kg):

[0029] Ammonium polyphosphate 45, melamine 15, polypentylthritol 12, urate 10, aluminum hydroxide 5, zinc borate 0.2, ionic surfactant 0.5.

[0030] The preparation method of the described halogen-free nitrogen and phosphorus composite intumescent flame retardant comprises the following steps:

[0031] According to the proportion, the raw materials ammonium polyphosphate, melamine, polypentyl glycolate, and urate are added to the reactor, and the temperature of the reactor is controlled by controlling the speed of the mixer in the reactor to increase slowly at 10°C / min, and keep at 100°C for 15 minutes, and pass Slowly add inorganic additives and zinc borate from the feeding port, slowly add ionic surfactant after 8 minutes, stop the reaction and discharge in 10 minutes.

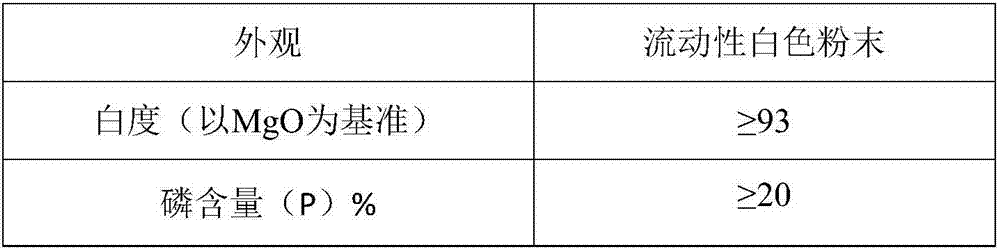

[0032] Quality Index:

[0033]

[0034]

[0035] Pr...

PUM

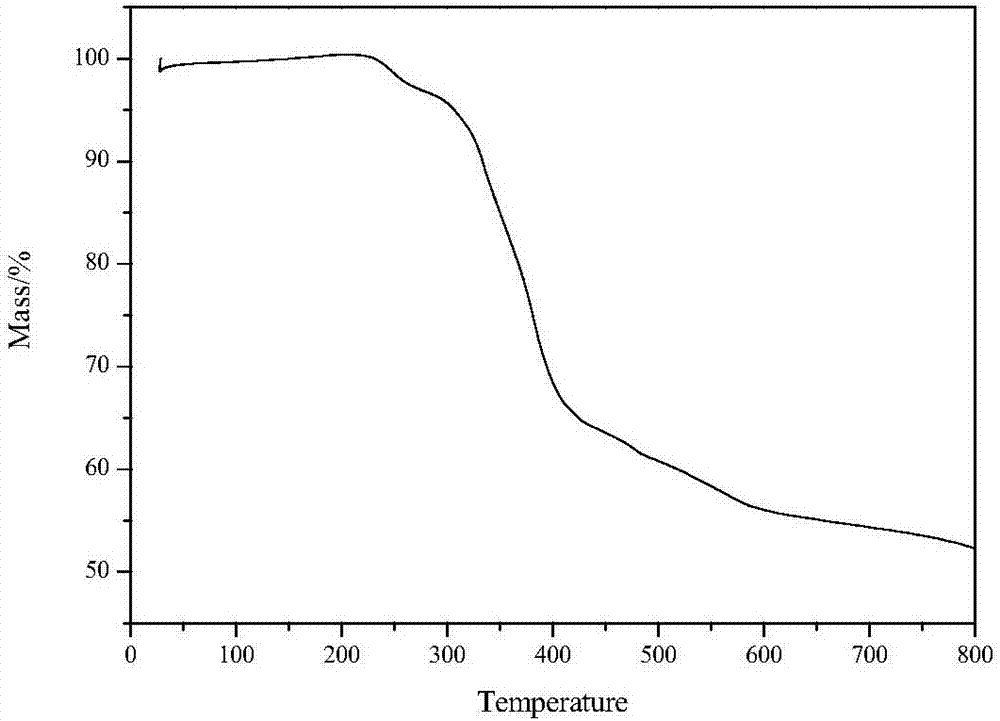

| Property | Measurement | Unit |

|---|---|---|

| decomposition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com