Pantograph slide plate material for locomotive and preparation method thereof

A technology for pantograph slides and railway locomotives, applied in the field of material preparation, can solve the problems of small current collection capacity, poor impact resistance, long cycle, etc., and achieve the effect of fine and smooth processing surface, easy industrial production, and short production cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

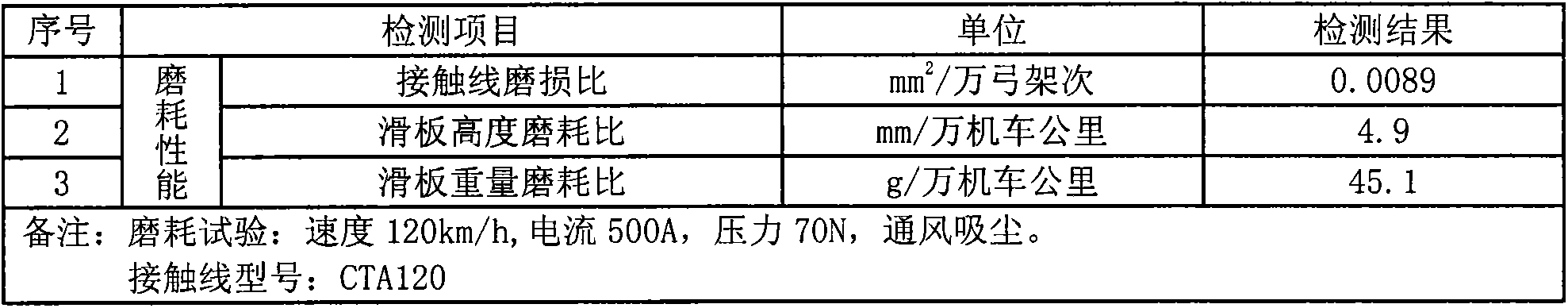

Image

Examples

Embodiment Construction

[0016] This material preparation method comprises the following steps:

[0017] 1. Selection and preparation of raw materials: select 0.2-0mm particle size pitch coke 30%, 200 mesh pitch coke 45%, 325 mesh graphite powder 20%, ultra-fine reinforcing body carbon black 5%, high temperature hard pitch bonding Agent 35%.

[0018] 2. Green body molding: Pitch coke, carbon black and graphite powder of different particle size and purity after crushing, screening and grinding, totaling 300Kg, poured into a 1000L kneading pot, heated with heat transfer oil and stirred for 60min to 110-120 ℃, mix the materials evenly, add 108kg of asphalt binder that has been melted and dehydrated at 155-160 ℃, and stir for 60 minutes until the temperature reaches 150-155 ℃. , to prevent cooling and agglomeration, and then add a 315T vertical extrusion molding machine to control the mouth temperature, extrusion pressure and pressure speed, extrude at a uniform speed, and place in cooling water to cool....

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com