High-performance amorphous graphite negative electrode material and low-cost preparation method thereof

A technology of microcrystalline graphite and negative electrode materials, applied in chemical instruments and methods, battery electrodes, inorganic chemistry, etc., can solve the problems of unsatisfactory cycle performance, high irreversible capacity loss, low tap density and fixed carbon content, etc. problems, to achieve the effect of avoiding purification treatment, high carbon residue rate and high density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

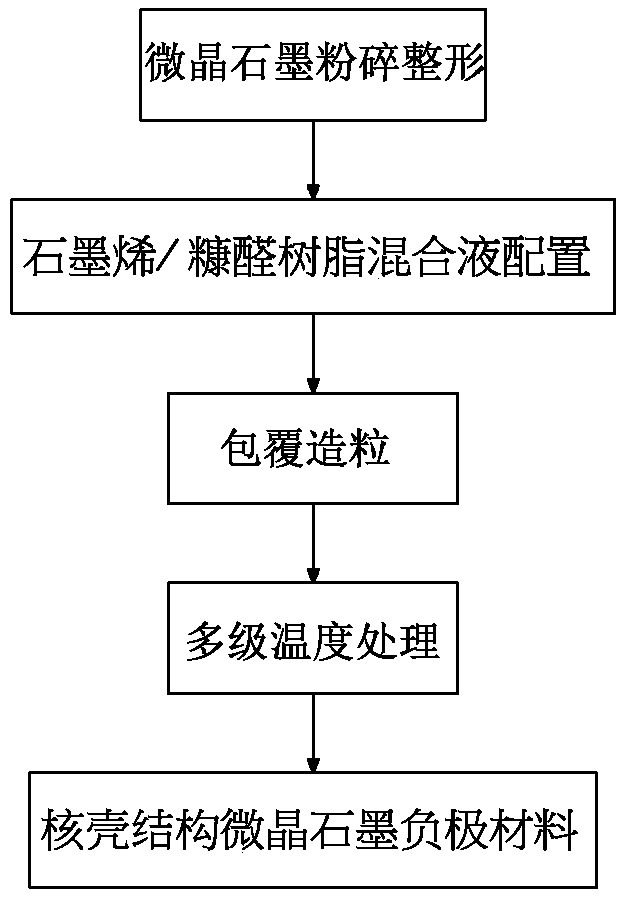

[0023] The invention discloses a low-cost preparation method of a high-performance microcrystalline graphite negative electrode material, which includes the following steps:

[0024] (1) Grinding and shaping: the microcrystalline graphite with a fixed carbon content ≥ 90% after preliminary flotation is pulverized by a mechanical mill and then put into a stirring ball mill, adding grinding aids, stirring and grinding, after grinding, the material is dried, and then air-selected Grading to obtain microcrystalline graphite microspheres with a particle size D50=5-15 μm and smooth surface, clean and free of floating powder;

[0025] The mechanical pulverization refers to pulverizing the dry concentrate obtained after preliminary flotation with an ultra-fine mechanical mill to obtain microcrystalline graphite powder with a particle size of D50=5-25 μm.

[0026] Described grinding, the grinding ball that adopts is agate ball, diameter 5-10mm, slurry concentration 10-20%; Material bal...

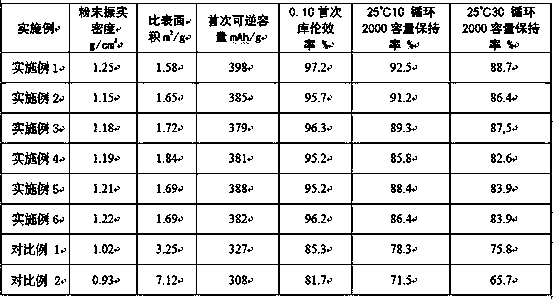

Embodiment 1

[0033] A low-cost preparation method of a high-performance microcrystalline graphite negative electrode material, comprising the following steps:

[0034] (1) Grinding and shaping: the microcrystalline graphite with a fixed carbon content of 91% after preliminary flotation is pulverized by a mechanical mill and then put into a stirring ball mill, adding grinding aids, stirring and grinding, and drying the ground material, and then air selection Grading to obtain microcrystalline graphite microspheres with a particle size of D50=12 μm, smooth surface, clean and free of floating powder;

[0035] The mechanical pulverization refers to pulverizing the dry concentrate obtained after preliminary flotation with an ultra-fine mechanical mill to obtain microcrystalline graphite powder with a particle size of D50=14 μm.

[0036] In the grinding, the grinding balls used are agate balls with a diameter of 5mm and a slurry concentration of 10%; the mass ratio of the balls to the balls is 1...

Embodiment 2

[0042] A low-cost preparation method of a high-performance microcrystalline graphite negative electrode material, comprising the following steps:

[0043] (1) Grinding and shaping: the microcrystalline graphite with a fixed carbon content of 93% after preliminary flotation is pulverized by a mechanical mill and then put into a stirring ball mill, adding grinding aids, stirring and grinding, and drying the ground material, and then air selection Grading to obtain microcrystalline graphite microspheres with a particle size of D50=14 μm, smooth surface, clean and free of floating powder;

[0044] The mechanical pulverization refers to pulverizing the dry concentrate obtained after preliminary flotation with an ultra-fine mechanical mill to obtain microcrystalline graphite powder with a particle size of D50=16 μm. In the grinding, the grinding balls used are agate balls with a diameter of 10mm and a slurry concentration of 20%; the mass ratio of the ball to the ball is 1:6, and th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com