Preparation method of amino POSS graft modified ablation-resistant phenolic resin and phenolic resin thereof

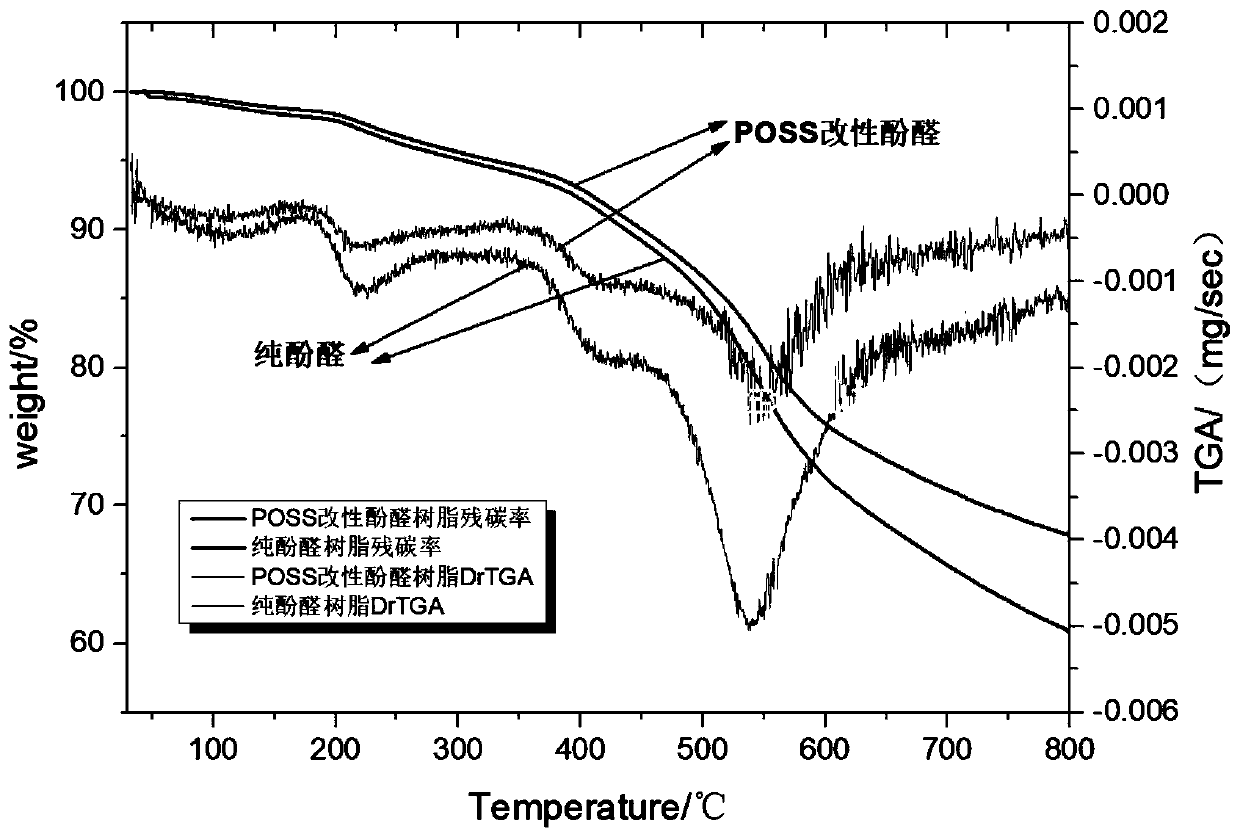

A technology of methylol phenolic resin and graft modification, applied in the field of phenolic resin and modified phenolic resin, can solve the problems of unsatisfactory ablation resistance and low modification efficiency of modified phenolic resin, and achieve the promotion of high-efficiency chemical Reaction modification, improvement of modification efficiency, excellent effect of ablation resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0029] The preparation method of the ablation-resistant phenolic resin of amino POSS graft modification of the present invention, comprises the steps:

[0030] (1) get phenol and aldehyde according to the molar ratio of 1:(1.0~1.5), then add catalyst wherein, react to generate the polymer containing hydroxymethyl phenolic resin;

[0031] (2) get amino POSS, the mass ratio of described amino POSS and the described phenol in step (1) is (1~10): 100, it is dissolved in the solvent, forms amino POSS solution;

[0032] (3) Add the amino POSS solution in the step (2) to the hydroxymethyl-containing phenolic resin polymer in the step (1), and react to generate the ablation-resistant phenolic resin modified by the amino POSS grafting resin.

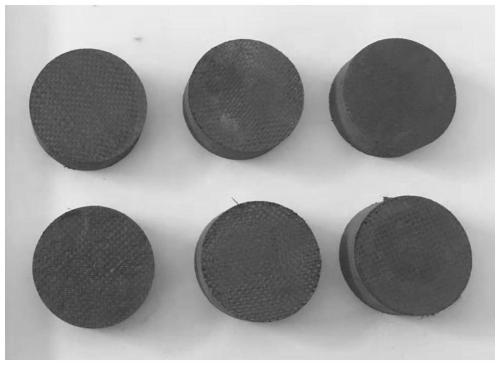

Embodiment 1

[0034] In the present embodiment, the preparation method of the ablation-resistant phenolic resin modified by amino POSS grafting comprises the following steps:

[0035] (1) Get phenol and formaldehyde according to the molar ratio of 1:1.2, add formaldehyde to the phenol after stirring under stirring, stir evenly, add catalyst barium hydroxide to wherein after cooling again, the quality of barium hydroxide accounts for 1 / 3 of the quality of phenol 1%, from room temperature to 80 ° C, through condensation reaction to generate a polymer containing hydroxymethyl phenolic resin;

[0036] (2) Get the cage type 8-anilino POSS, the mass ratio of the cage type 8-anilino POSS to the phenol in step (1) is 5:100, dissolve it in acetone to form an amino POSS solution ;

[0037] (3) After the condensation reaction in the step (1) is carried out for 1.5h, add the amino POSS solution described in the step (2) to the described hydroxymethyl phenolic resin polymer in the step (1), at 80 ~ Co...

Embodiment 2

[0042] In the present embodiment, the preparation method of the ablation-resistant phenolic resin modified by amino POSS grafting comprises the following steps:

[0043] (1) get methyl phenol and formaldehyde according to the mol ratio of 1:1.3, add formaldehyde in methyl phenol under stirring, stir evenly, add catalyst ammonia water to wherein after cooling again, ammonia water accounts for 0.5% of methyl phenol quality, From room temperature to 80°C, the condensation reaction produces a polymer containing hydroxymethyl phenolic resin;

[0044] (2) Get the cage type 8-anilino POSS, the mass ratio of the cage type 8-anilino POSS to the phenol in step (1) is 8:100, dissolve it in acetone to form amino POSS solution ;

[0045] (3) After the condensation reaction in the step (1) is carried out for 1h, add the amino POSS solution described in the step (2) to the described hydroxymethyl phenolic resin polymer in the step (1), at 80~95 Continue to react at a temperature of ℃ to th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| ablation rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com