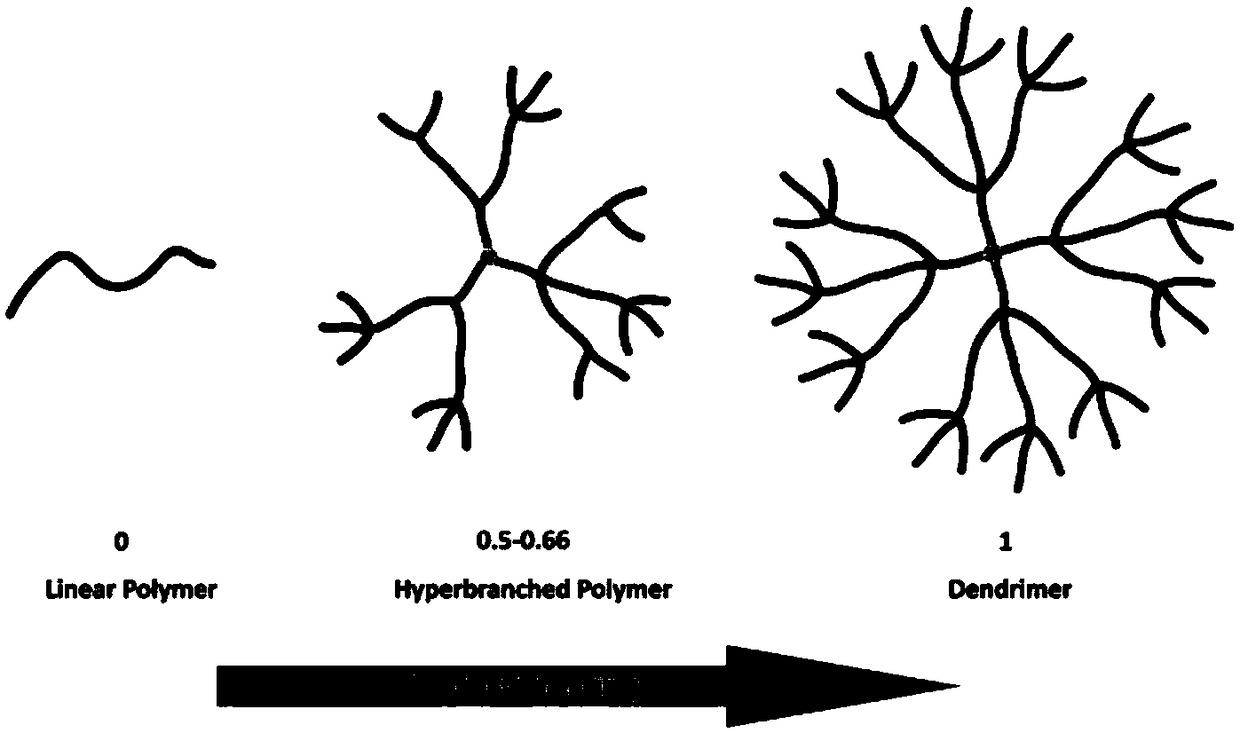

Synthetic method of hyperbranched polymer and application of hyperbranched polymer in modified thermosetting resin

A technology of hyperbranched polymers and synthesis methods, applied in the field of polymer synthesis, can solve the problems of numerous side reactions, expensive raw materials, and high synthesis costs, and achieve the effects of simple equipment and devices, reduced production costs, and a wide range of applications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] In a four-necked flask equipped with a stirrer, a thermometer, a condenser, and a source of high-purity argon gas, add tetraethyl orthosilicate, neopentyl glycol, and a catalyst according to the stoichiometric amount, raise the temperature to 60°C and keep it warm for 1h, then lower the temperature Rapidly raised to 200°C, reacted for 3 hours, cooled to 80°C and discharged to obtain a hyperbranched polymer. The obtained hyperbranched polymer is added to the epoxy resin according to a certain proportion, heated and stirred evenly, and a measured amount of epoxy resin curing agent is added. After vacuum defoaming, it is cured according to the standard procedure, and finally the cured sample is obtained by demoulding. The cured epoxy resin increases the tensile strength by more than 20%, the bending strength by more than 30%, and the impact strength by 300% compared with the control group without hyperbranched polymer.

Embodiment 2

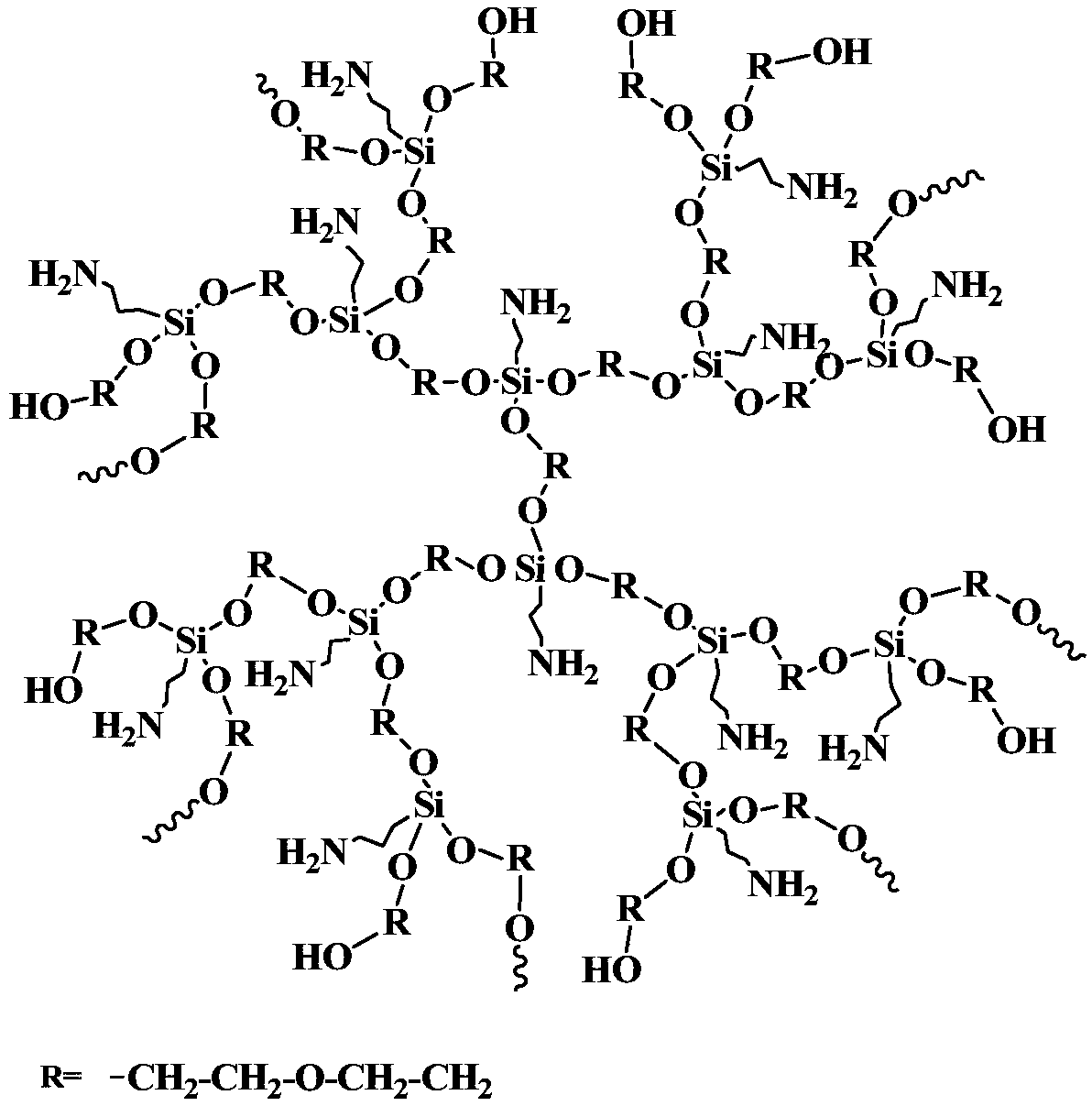

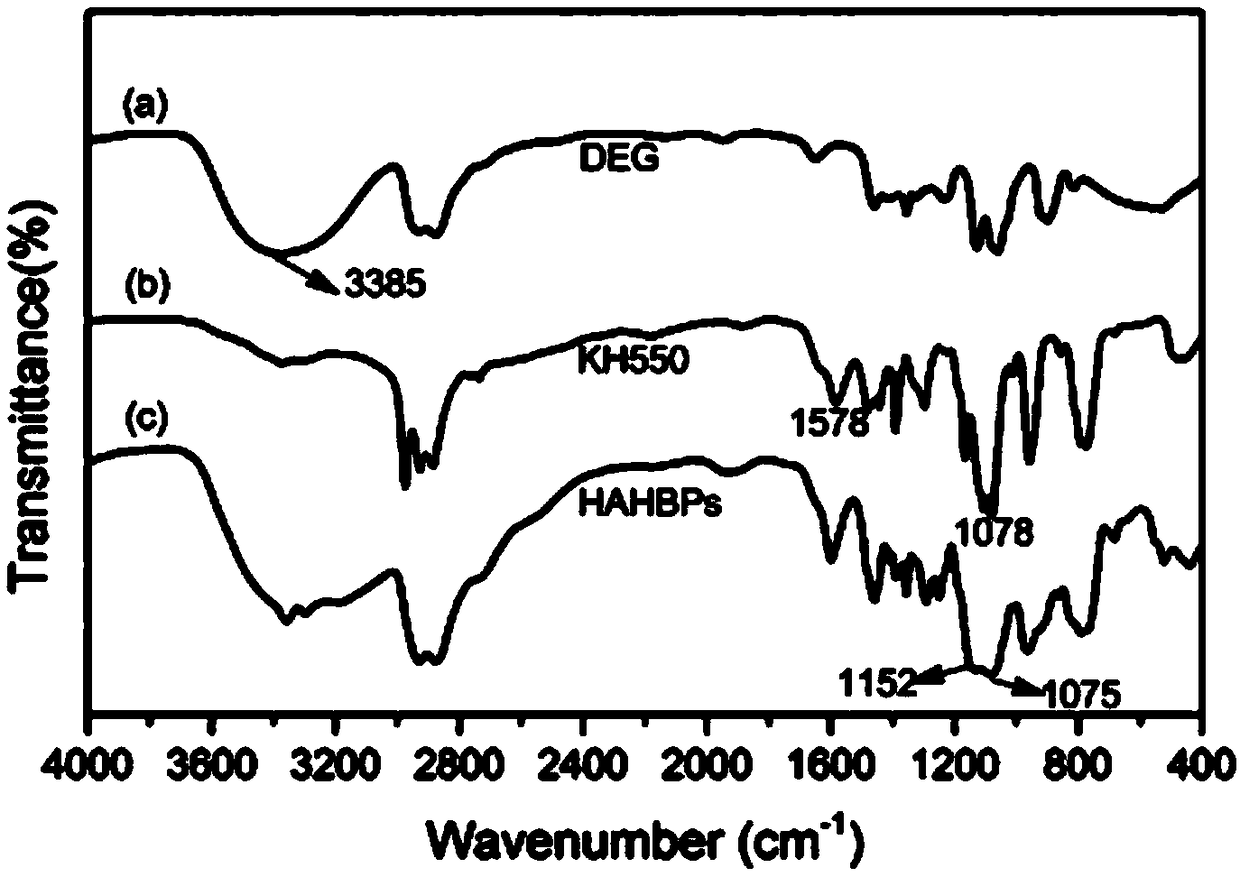

[0053] In a four-necked flask equipped with a stirrer, a thermometer, a condenser, and a source of high-purity argon gas, add coupling agent KH550, neopentyl glycol, and a catalyst according to stoichiometric amounts, raise the temperature to 70°C and keep it warm for 1.5h, then lower the temperature to Rapidly raised to 180°C, reacted for 3 hours, cooled to 50°C and discharged to obtain a hyperbranched polymer. The obtained hyperbranched polymer is added to the epoxy resin according to a certain proportion, heated and stirred evenly, and a measured amount of epoxy resin curing agent is added. After vacuum defoaming, it is cured according to the standard procedure, and finally the cured sample is obtained by demoulding. Compared with the control group without adding hyperbranched polymer, the tensile strength of the cured epoxy resin increased by more than 10%, the flexural strength increased by more than 25%, and the impact strength increased by 350%.

Embodiment 3

[0055] In a four-necked flask equipped with a stirrer, a thermometer, a condenser, and a source of high-purity argon gas, add coupling agent KH560, neopentyl glycol, and a catalyst according to stoichiometric amounts, raise the temperature to 60°C and keep it for 2 hours, and then rapidly lower the temperature to Raise to 190°C, react for 4 hours, cool down to 50°C and discharge to obtain a hyperbranched polymer. The obtained hyperbranched polymer is added to the cyanic acid resin according to a certain proportion, heated and stirred evenly, and cured according to the standard procedure after vacuum defoaming, and finally demoulded to obtain the cured sample. The cured epoxy resin increases the tensile strength by more than 15%, the flexural strength by more than 20%, and the impact strength by 250% compared with the control group without hyperbranched polymer.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com