Oil intelligent-blending system for nylon production

An oily and intelligent technology, applied in the field of nylon production, can solve the problems of easy tow floating, low tow quality, untimely feedback, etc., and achieve the effects of convenient reuse, recycling, and avoiding contact impact.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

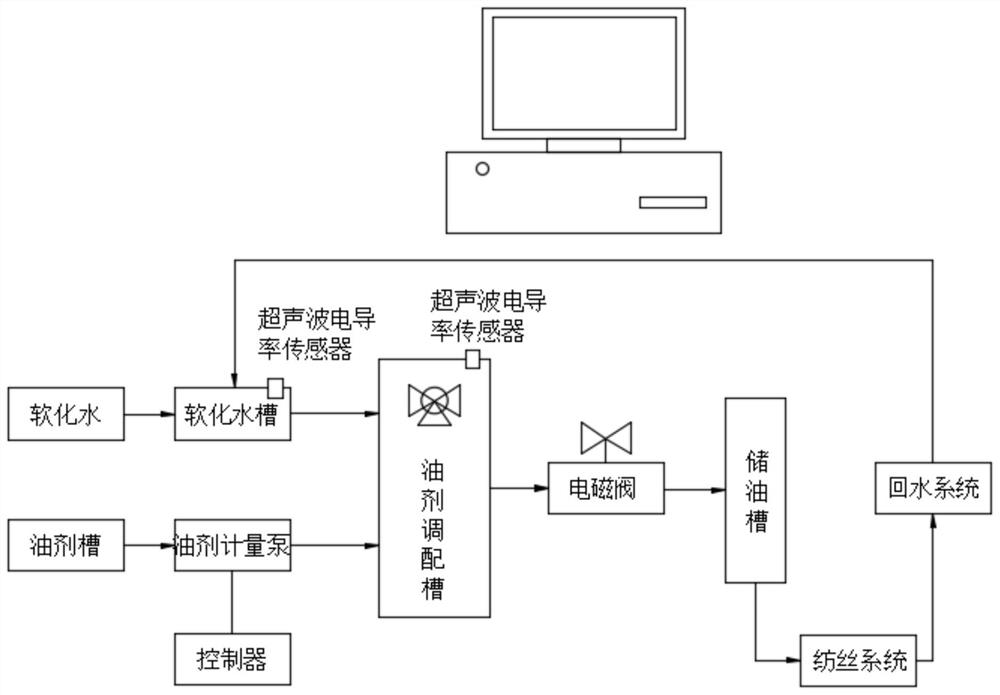

[0042] see figure 1 , an intelligent oil preparation system for nylon production, including a softening water tank and an oil preparation tank, the softening water tank is connected to an oil preparation preparation tank, the oil preparation tank is connected to an oil preparation metering pump, and the oil agent metering pump is connected to the oil preparation preparation tank , the softening water tank and the oil preparation tank are equipped with ultrasonic conductivity sensors, the ultrasonic conductivity sensors are connected to the control terminal, the control terminal can be a computer, the oil preparation tank is connected to a solenoid valve, and the solenoid valve is connected to the control terminal, and the electromagnetic valve is connected to the control terminal. The valve is connected with an oil storage tank, the oil storage tank is connected with a spinning system, the spinning system is connected with a return water system, and the return water system is c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com