Polymer-metal ion complex gel electrolyte and preparation method and application thereof

A technology of gel electrolyte and metal ions, which is applied in the direction of capacitor electrolyte/absorbent, circuit, photovoltaic power generation, etc., can solve the problems of cumbersome gel electrolyte method and the inability to guarantee the contact performance of the interface between the electrolyte and the working electrode, so as to overcome the possibility of preparation Poor operability, excellent machinability, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Add 100 mL of toluene into a 250 mL three-necked flask, add 5 mL of 4-vinylpyridine and 20 mL of acrylonitrile into it under magnetic stirring, and control the temperature at 70°C under a nitrogen atmosphere. Azobisisobutyronitrile was added, and after 2 hours, the reaction was stopped and cooled. The product generated by the reaction was obtained by filtration, washed with toluene for 2 times, and then washed with anhydrous ether for 3 times. Put the treated product into a vacuum oven and dry at 50° C. for 48 hours to obtain a copolymer of 4-vinylpyridine and acrylonitrile. Wherein, the molar percentage of 4-vinylpyridine is 25%. The number average molecular weight of the obtained polymer was 4,000.

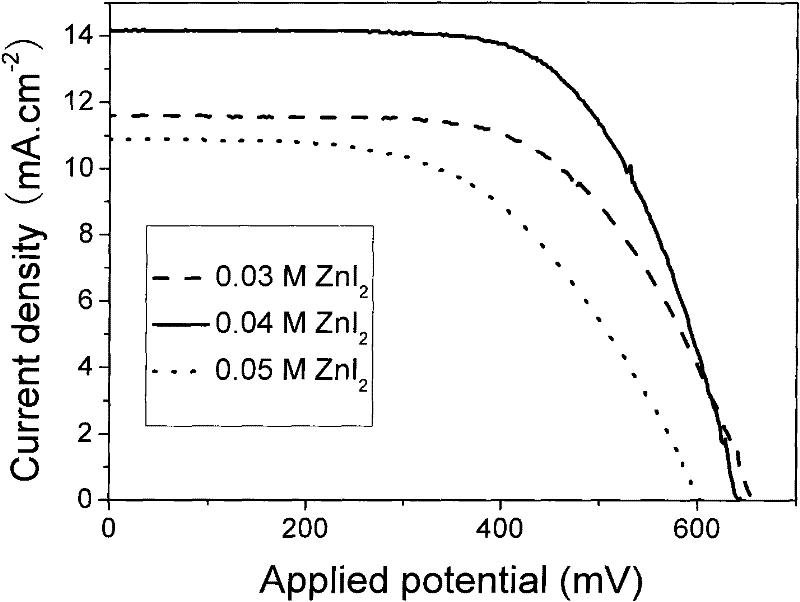

[0035] Get above-mentioned gained copolymer 0.015g, 0.16g EC, 0.04g PC, 0.0083g KI, 0.0015g I 2 Add it to a 5ml weighing bottle, stir to dissolve it, and then add 0.014g ZnI 2 , stirred to make it dissolve completely, and the polymer-metal ion complex gel electrolyte ...

Embodiment 2

[0038]Add 60 mL of toluene into a 100 mL three-necked flask, add 2 mL of 4-vinylpyridine and 8 mL of acrylonitrile into it under magnetic stirring, and control the temperature at 80°C under a nitrogen atmosphere. Azobisisobutyronitrile was added, and after 2 hours, the reaction was stopped and cooled. The product generated by the reaction was obtained by filtration, washed with toluene for 2 times, and then washed with anhydrous ether for 4 times. Put the treated product into a vacuum oven and dry at 40° C. for 40 hours to obtain a copolymer of 4-vinylpyridine and acrylonitrile. Wherein, the molar percentage of 4-vinylpyridine is 26%, and the data molecular weight of the obtained polymer is 4000.

[0039] Get above-mentioned gained copolymer 0.045g, 0.48g EC, 0.12g PC, 0.0249g KI, 0.0045g I 2 Add it to a 5ml weighing bottle, stir to dissolve it, and then add 0.06g ZnI 2 , stirred to make it dissolve completely, and the polymer-metal ion complex gel electrolyte was obtained....

Embodiment 3

[0042] Add 250 mL of toluene into a 500 mL three-necked flask, add 10 mL of 4-vinylpyridine and 40 mL of acrylonitrile into it under magnetic stirring, and control the temperature at 85°C under a nitrogen atmosphere. Benzoyl peroxide was added, and after 2.5 hours, the reaction was stopped and cooled. The product generated by the reaction was obtained by filtration, washed with toluene for 4 times, and then washed with anhydrous ether for 5 times. Put the treated product into a vacuum oven and dry at 55° C. for 56 hours to obtain a copolymer of 4-vinylpyridine and acrylonitrile. Wherein, the molar percentage of 4-vinylpyridine is 24%, and the number average molecular weight of the obtained polymer is 4000.

[0043] Get above-mentioned gained copolymer 0.015g, 0.16g EC, 0.04g PC, 0.0083g KI, 0.0015g I 2 Add it to a 5ml weighing bottle, stir to dissolve it, and then add 0.009g ZnI 2 , stirred to make it dissolve completely, and the polymer-metal ion complex gel electrolyte wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com