Multi-phase copolymer polypropylene in-reactor alloy and preparation method thereof

A technology of in-kettle alloy and polypropylene, which is applied in the field of heterogeneous copolymer polypropylene in-kettle alloy and its preparation, can solve the problems of inability to adjust the molecular structure diversity of the rubber phase, poor catalytic copolymerization ability, and very limited control of material properties, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

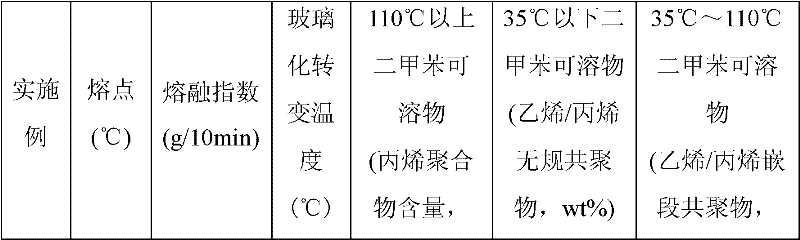

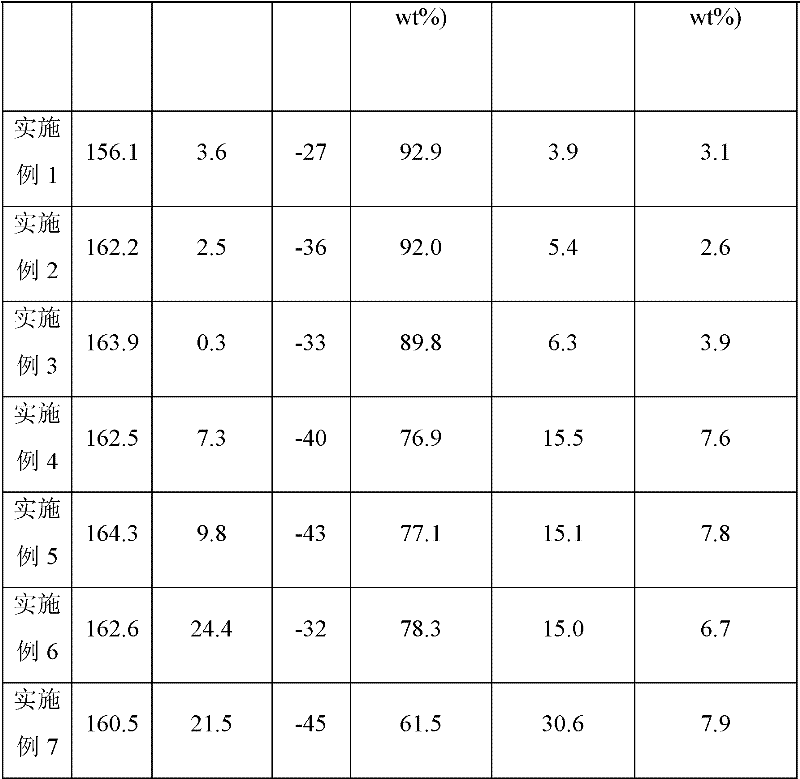

Embodiment 1

[0049] (1) Propylene polymerization

[0050] Add 2Kg propylene in a 10L polymerization reactor, and add 0.076g of external electron donor diphenyldimethoxysilane (DDS) successively at 20°C (the amount of this external electron donor is 2% of the molar amount of metal Ti element in the catalyst. 13 times), cocatalyst triethylaluminum (TEA) 0.58g (the addition of this cocatalyst is based on the mol ratio of Al and metal Ti in the catalyzer, is Al: Ti=212), Ziegler-Natta / metallocene composite catalyst A 0.05g, 0.3g of hydrogen gas was passed through, the temperature was raised to 75°C, and the pressure was 3.2MPa to react for 60min, and the obtained polypropylene was directly subjected to the next step of reaction.

[0051] (2) Ethylene / propylene copolymerization

[0052] Vent the remaining propylene in the reaction kettle in step 1 and lower the temperature to 50°C, then feed a mixture of 100g ethylene and 350g propylene, and 0.05g hydrogen, raise the temperature to 80°C, and r...

Embodiment 2

[0054] (1) Propylene polymerization

[0055] Add 2Kg of propylene into a 10L polymerization reactor, add 0.05g of Ziegler-Natta / metallocene composite catalyst B at 20°C, pass in 0.25g of hydrogen, raise the temperature to 70°C, and react for 60min under a pressure of 3MPa, and the obtained polypropylene is directly proceed to the next reaction.

[0056] (2) Ethylene / propylene copolymerization

[0057] In step 1), the residual propylene in the reactor was vented and cooled to 50°C, then a mixture of 100g ethylene and 350g propylene was introduced, 0.05g hydrogen was introduced, the temperature was raised to 80°C, and the pressure was 2.5MPa to react for 30 minutes to obtain The polypropylene kettle alloy is 1.12Kg, and the composition and properties of the product are shown in Table 1, wherein, as one of the components, the average isotacticity of xylene solubles above 110°C (that is, propylene polymer) is 95%.

Embodiment 3

[0059] (1) Homopolymerization of propylene

[0060] In a 10L polymerization reactor, add 2Kg propylene, and add cocatalyst triethylaluminum (TEA) 0.36g successively at 20°C (the addition amount of the cocatalyst is based on the molar ratio of Al to metal Ti in the catalyst, which is Al:Ti =109), Ziegler-Natta / metallocene composite catalyst C 0.05g, the temperature was raised to 75°C, and the pressure was 3.0MPa to react for 45min, and the obtained polypropylene was directly subjected to the next reaction.

[0061] (2) Ethylene / propylene copolymerization

[0062] Vent the remaining propylene in the reaction kettle in step 1) and lower the temperature to 50°C, then introduce a mixture of 150g ethylene and 300g propylene, raise the temperature to 90°C, and react for 30min at a pressure of 2.3MPa to finally obtain a polypropylene kettle alloy 1.03 Kg, the composition and properties of the product are shown in Table 1, wherein, as one of the components, the average isotacticity of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com