Environment-friendly modified polypropylene profiled bar base station antenna casing and preparation method

An environment-friendly, base station antenna technology, applied in the field of special-shaped material housing and its preparation, can solve the problems of poor weather resistance and aging resistance, achieve low dielectric loss tangent, balance rigidity, and improve the effect of UV resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

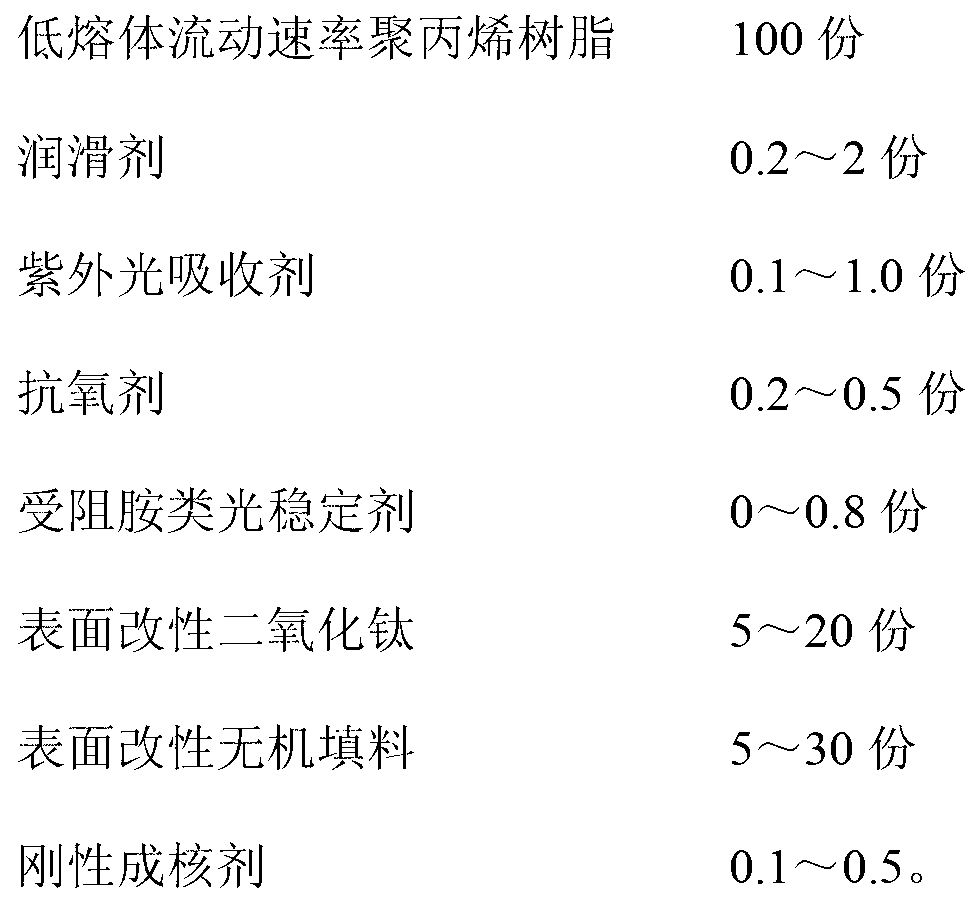

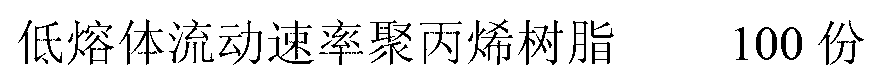

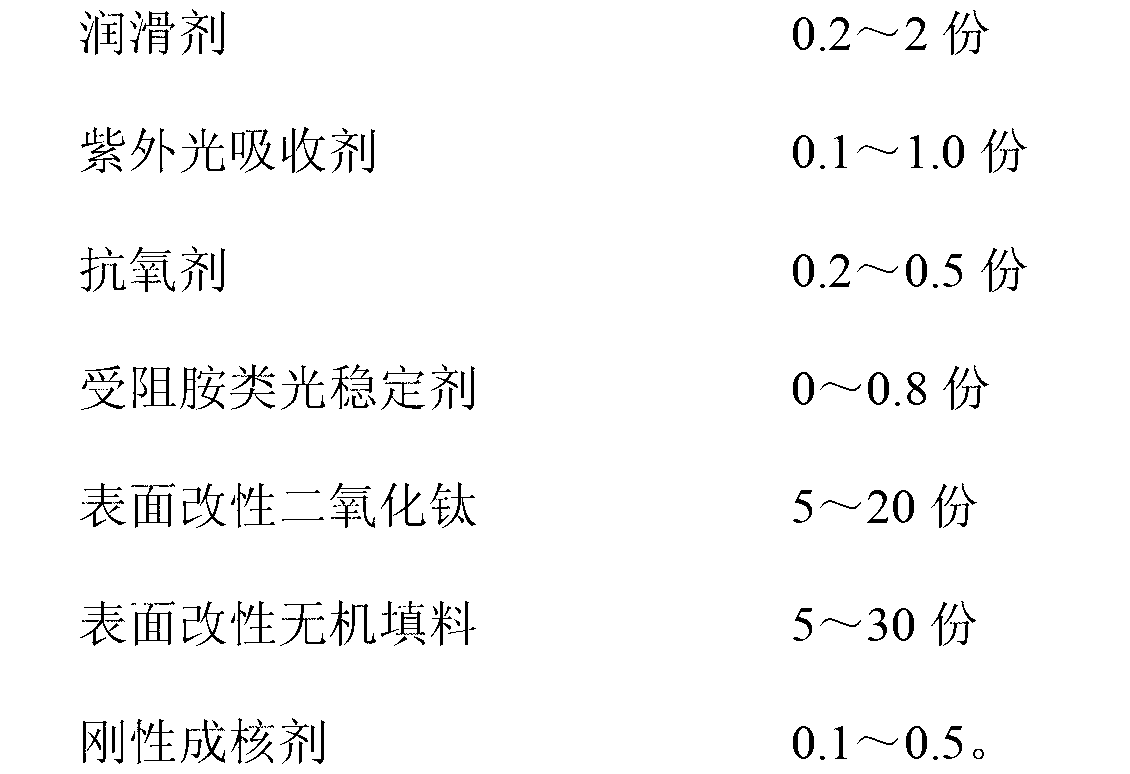

Method used

Image

Examples

Embodiment 1

[0037] Raw material formula: homopolypropylene (melt flow rate measured at 230°C×2160g=0.8g / 10min) 35, random copolymerized polypropylene (melt flow rate measured at 230°C×2160g=0.5g / 10min) 65, Stearic acid 0.1, calcium stearate 0.1, ultraviolet absorber UV 531 0.5, antioxidant 1010 0.3, hindered amine light stabilizer C944 0.3, rutile TiO 2 10. Surface modification of CaCO 3 20. Nucleating agent NAA325 0.2.

[0038] Preparation Process:

[0039] ① Pre-dispersion of functional additives: Put 10 parts of random copolymerized PP resin powder and all lubricants, ultraviolet light absorbers, antioxidants, hindered amine light stabilizers, and rigid nucleating agents into the high-speed mixer And other functional additives, control the speed of the mixer at a low speed below 500rpm and stir for 3 minutes at a material temperature of about 40°C to discharge to the silo.

[0040] ②Surface modification of inorganic fillers: First, add 100 kg of CaCO to a high-speed mixer with tem...

Embodiment 2

[0046] Raw material formula: homopolypropylene (melt flow rate measured at 230°C×2160g=0.3g / 10min) 60, random copolymerized polypropylene (melt flow rate measured at 230°C×2160g=0.3g / 10min) 40, Zinc stearate 0.1, oleic acid amide 0.1, ultraviolet absorber UV 326 0.5, antioxidant B215 0.2, hindered amine light stabilizer T770 0.2, rutile TiO 2 5. Surface modified mica 25, nucleating agent NAP-71 0.1.

[0047] Preparation Process:

[0048] ① Pre-dispersion of functional additives: Put 10 parts of homopolymer PP resin powder in the formula and all lubricants, ultraviolet light absorbers, antioxidants, hindered amine light stabilizers, rigid nucleating agents, etc. into the high-speed mixer Functional additives, control the speed of the mixer at a low speed below 500rpm, stir for 6 minutes, and discharge to the silo at a material temperature of about 40°C.

[0049] ②Surface modification of inorganic fillers: First, add 100 kg of mica to a high-speed mixer at a temperature contr...

Embodiment 3

[0055] Raw material formula: random copolymerized polypropylene (melt flow rate measured at 230°C×2160g=0.5g / 10min) 30, block copolymerized polypropylene (melt flow rate measured at 230°C×2160g=0.5g / 10min) 70 , zinc stearate 0.2, magnesium stearate 0.3, UV absorber UV 326 0.3, UV absorber UV 531 0.2, antioxidant 168 0.2, antioxidant 1010 0.2, hindered amine light stabilizer T770 0.1, Hindered amine light stabilizer HS-765 0.1, rutile TiO 2 15, surface modified talc powder 5, surface modified attapulgite 15, nucleating agent NAP-71 0.1, nucleating agent NAA325 0.1.

[0056] Preparation Process:

[0057] ① Pre-dispersion of functional additives: Put 10 parts of block copolymerized PP resin powder and all lubricants, ultraviolet light absorbers, antioxidants, hindered amine light stabilizers, and rigid nucleating agents into the high-speed mixer And other functional additives, control the speed of the mixer at a low speed below 500rpm and stir for 5min at a material temperatur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com