High-content-rice husk fiber-filled PBAT-based composite material and preparation method and application thereof

A composite material, high-content technology, applied in the field of degradable materials, can solve the problems of high production cost, insufficient tensile strength, flexural modulus rigidity index, high price, etc., and achieve low production cost, low price and easy control Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

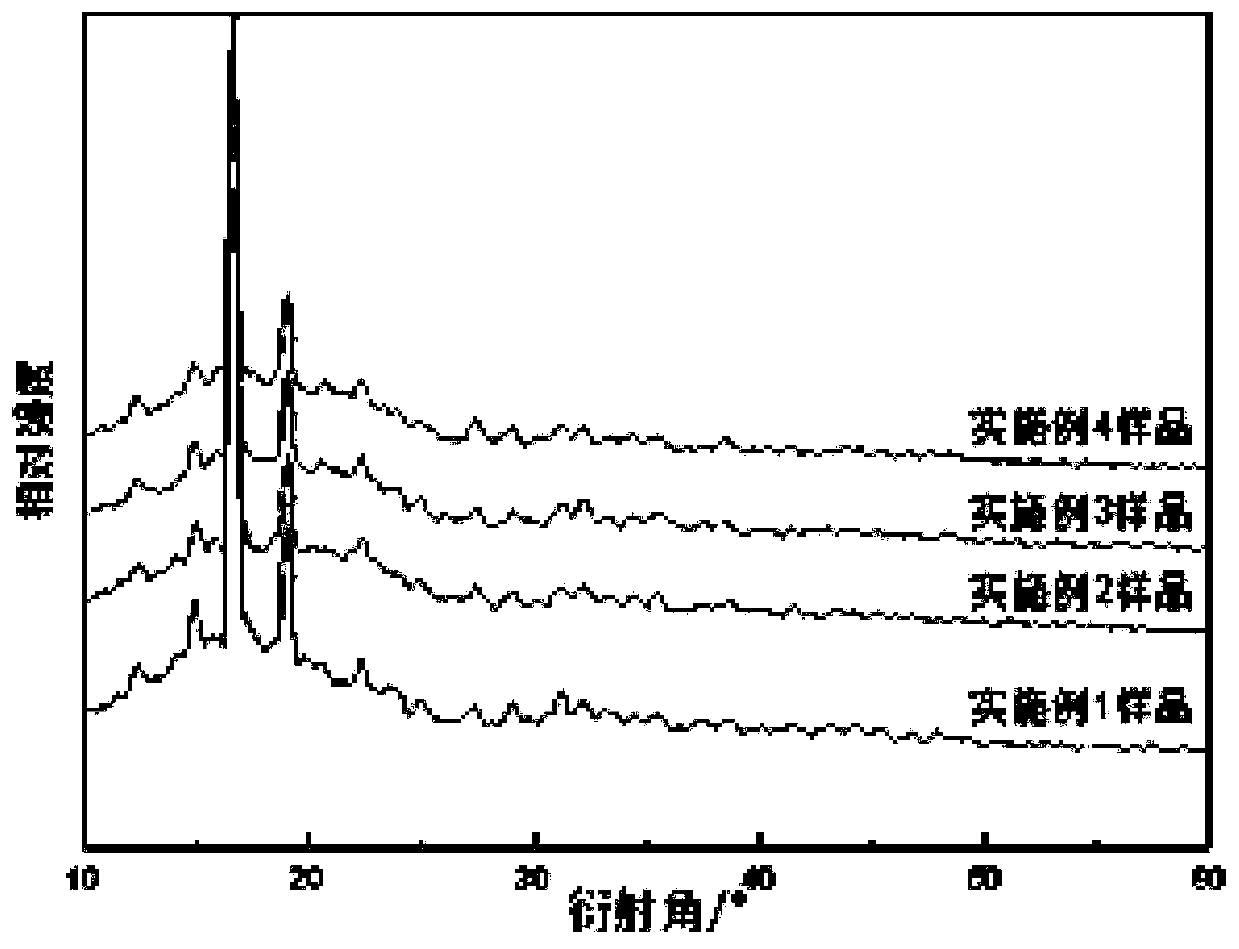

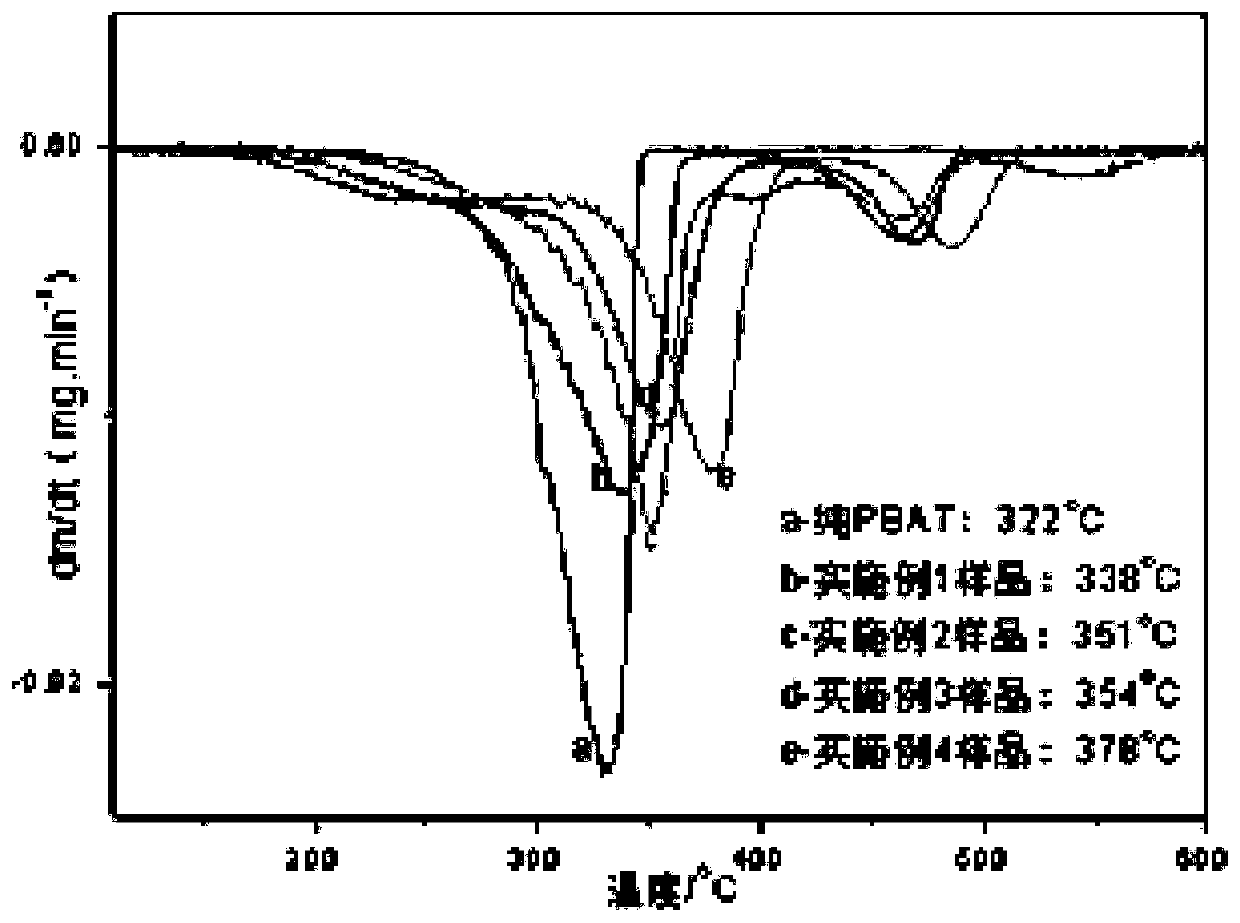

Embodiment 1

[0026] A PBAT-based composite material filled with high rice husk fiber content, comprising the following parts by weight: 100 parts of rice husk powder, 90 parts of PBAT, 10 parts of PLA, 2 parts of hyperdispersant CH-1A, 5 parts of PBS-g-MAH, hard 1 part of calcium stearate, 2 parts of stearic acid.

[0027] Its preparation method comprises the following steps:

[0028] A. Put 80-mesh rice husk powder with a fiber aspect ratio of 10 in a drying oven at 70°C for 12 hours;

[0029] B. Put the dried rice husk powder in step A into a high-speed mixer, add hyperdispersant, and mix and stir at 110°C for 8 minutes; then add PLA, PBS-g-MAH, continue stirring for 1 minute, and then add PBAT, Calcium stearate, stearic acid, continue to mix and stir for 1min;

[0030] C. After crushing the material mixed in step B, it is added to the twin-screw extruder. From the feed to the discharge port, the temperatures of the six heating sections are 145°C, 160°C, 170°C, and 170°C respectively. ...

Embodiment 2

[0034] A PBAT-based composite material filled with high rice husk fiber content, comprising the following parts by weight: 100 parts of rice husk powder, 80 parts of PBAT, 15 parts of PLA, 3 parts of hyperdispersant CH-2C, 13 parts of PBS-g-GMA, hard 2.5 parts of calcium stearate, 3 parts of stearic acid.

[0035] Its preparation method comprises the following steps:

[0036] A. Place the rice husk powder with an average particle size of 90 mesh and a fiber aspect ratio of 20 in an oven at 80°C for 11 hours;

[0037] B. Put the dried rice husk powder in step A into a high-speed mixer, add hyperdispersant, and mix and stir for 10 minutes at 120°C; then add PLA, PBS-g-GMA, continue stirring for 2 minutes, and then add PBAT, Calcium stearate, stearic acid, continue to mix and stir for 2 minutes;

[0038] C. After crushing the mixed material in step B, put it into the twin-screw extruder. From the feed to the discharge port, the temperatures of the six heating sections are 155°C...

Embodiment 3

[0042] A PBAT-based composite material filled with high rice husk fiber content, comprising the following parts by weight: 100 parts of rice husk powder, 70 parts of PBAT, 25 parts of PLA, 5 parts of hyperdispersant CH-6, 20 parts of PLA-g-GMA, hard 4 parts of barium stearate, 4 parts of stearic acid.

[0043] Its preparation method comprises the following steps:

[0044] A. Place the rice husk powder with an average particle size of 100 mesh and a fiber aspect ratio of 30 in a drying oven at 90°C for 10 hours;

[0045] B. Put the dried rice husk powder in step A into a high-speed mixer, add hyperdispersant, and mix and stir for 12 minutes at 130°C; then add PLA, PLA-g-GMA, continue stirring for 3 minutes, and then add PBAT, Barium stearate, stearic acid, continue to mix and stir for 3 minutes;

[0046] C. After crushing the mixed material in step B, put it into the twin-screw extruder. From the feed to the discharge port, the temperatures of the six heating sections are 165...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Impact strength | aaaaa | aaaaa |

| Impact strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com