High-weather-resistant high-tenacity reinforced polypropylene material for post insulator and preparation method of reinforced polypropylene material

A post insulator and polypropylene material technology, applied in the field of post insulator reinforced polypropylene material with high weather resistance and high toughness and its preparation, can solve the problems of polypropylene material aging, poor weather resistance and physical performance deterioration of polypropylene, and achieve Effects of reducing damage, reducing luster, and stabilizing color

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

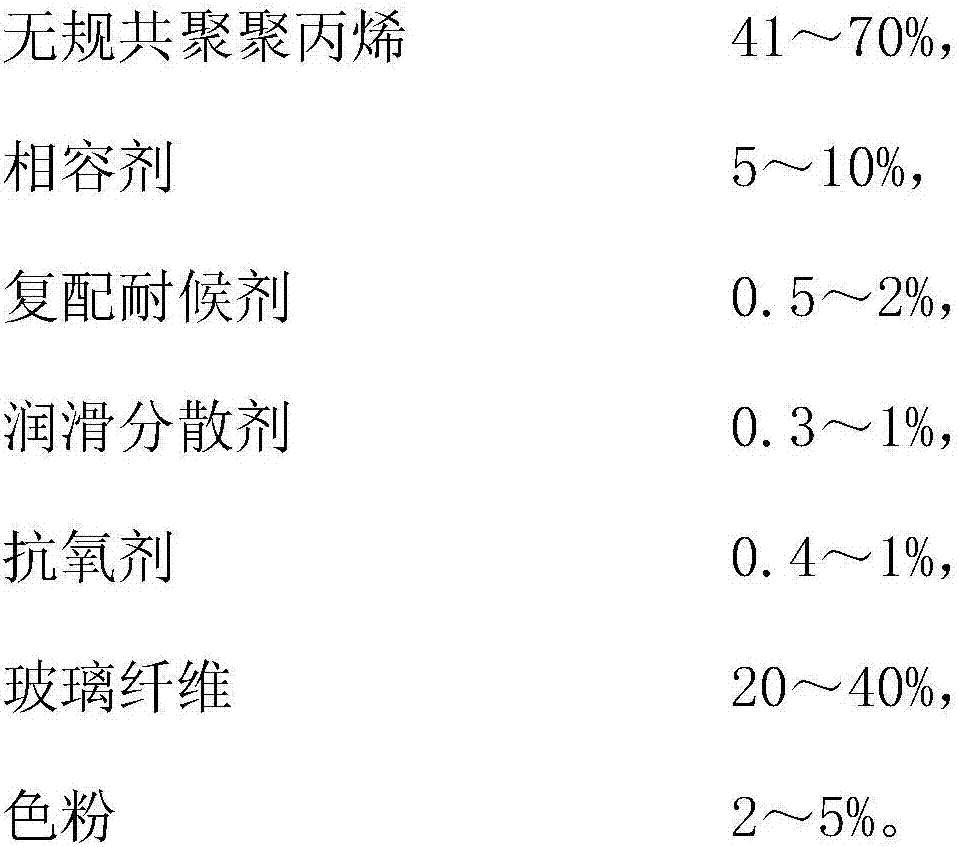

Method used

Image

Examples

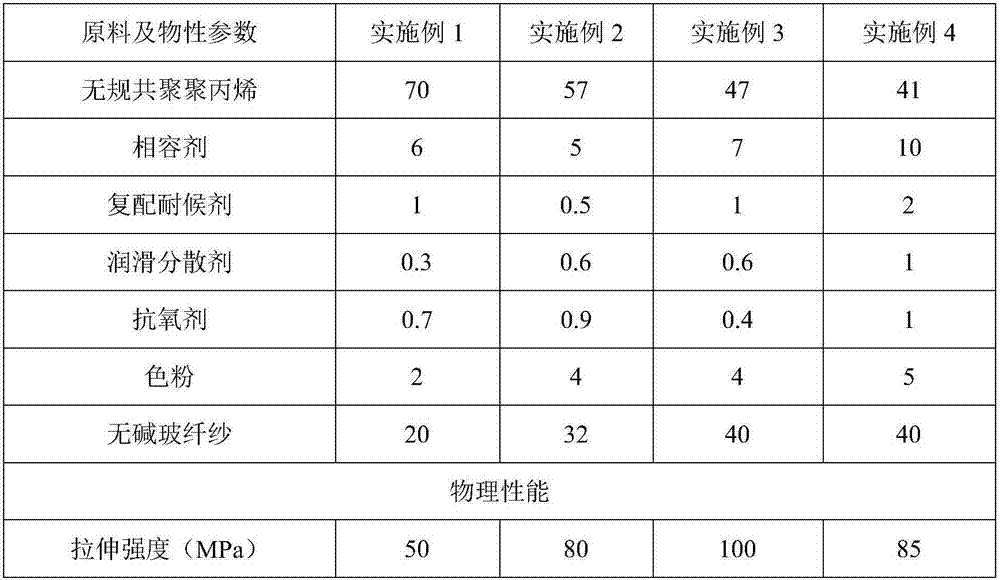

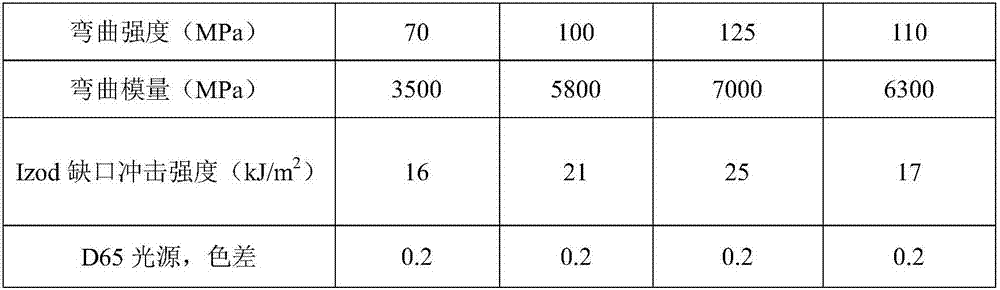

Embodiment 1

[0026] Weigh the raw materials according to the weight ratio, 70 parts of random copolymer polypropylene resin, 20 parts of alkali-free glass fiber yarn, 6 parts of compatibilizer (maleic anhydride and polyethylene), and compound weathering agent (anti-ultraviolet absorber) 1 part, lubricating dispersant (EBS mixed with polyethylene wax) 0.3 part, antioxidant (hindered phenols) 0.7 part, green toner 2 parts, mix in a high-speed mixer for 5-8 minutes, and then mix the mixed material It is placed in a twin-screw extruder for melting and granulation. The extrusion process is: the temperature in the first zone is 150℃, the second to fourth zone is 170~185℃, and the fifth to ninth zone is 185~ 210℃, head temperature is 205℃, screw speed of main engine is 350~420rpm, feeding frequency is 18~24Hz.

Embodiment 2

[0028] Weigh the raw materials according to the weight ratio, random copolymer polypropylene resin 57 parts, alkali-free glass fiber yarn 32 parts, compatibilizer (methacrylic acid and glycidyl methacrylate and styrene and butadiene) 5 Parts, 0.5 parts of weathering agent (light stabilizer), 0.6 part of lubricating dispersant (calcium stearate), 0.9 part of antioxidant (thioester antioxidant), 4 parts of green toner, mixed at high speed The machine is mixed for 5-8 minutes, and then the mixed material is placed in a twin-screw extruder to be melted and pelletized. The extrusion process is as follows: the temperature in the first zone is 150℃, and the second to fourth zone is 170~ 185℃, zone 5~9 zone 185~210℃, temperature of machine head is 205℃, screw speed of main engine 350~420rpm, feeding frequency 18~24Hz.

Embodiment 3

[0030] Weigh the raw materials according to the weight ratio: 47 parts of random copolymer polypropylene resin, 40 parts of alkali-free glass fiber yarn, 7 parts of compatibilizer (copolymer of acrylic acid and styrene and butadiene), and compound weathering agent ( Anti-ultraviolet absorber and light stabilizer mixed) 1 part, lubricating dispersant (mixed zinc stearate and silicone powder) 0.6 part, antioxidant (thioester antioxidant) 0.4 part, green toner 4 parts, Mix in a high-speed mixer for 5-8 minutes, then place the mixed material in a twin-screw extruder for melting and granulation. The extrusion process is as follows: the temperature in the first zone is 150°C, the second to the fourth zone It is 170~185℃, zone 5~9 is 185~210℃, head temperature is 205℃, screw speed of main engine is 350~420rpm, feeding frequency is 18~24Hz.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com