Polyphenyl ether polypropylene resin composition and preparation method thereof

A technology of polypropylene resin and polyphenylene ether, which is applied in the field of resin composition and its preparation, can solve the problems of increasing molding cycle and energy consumption, low stiffness of the composition, etc., and achieve an excellent balanced effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

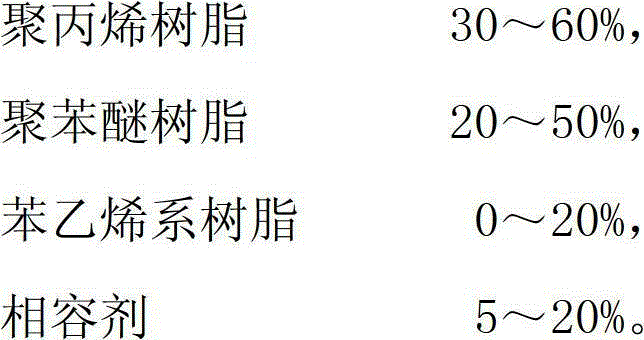

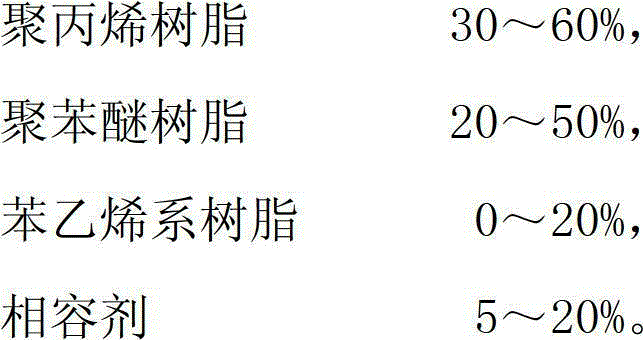

[0043] The polyphenylene ether polypropylene resin composition of the present embodiment comprises each component of the proportioning shown in Table 1;

[0044] In this example, the polypropylene resin used is the homopolypropylene resin of Shanghai Petrochemical Co., Ltd., and the MFR measured according to ASTM D-1238 at 230°C and a load of 2.16kg is 5-10g / 10min; the polyphenylene ether resin is Bluestar The poly(2,6-dimethyl-1,4-phenylene) ether resin of Chemical New Materials Co., Ltd. is measured with chloroform solution at 30°C. Its relative viscosity is 0.30-0.50, and its weight average molecular weight and number average The molecular weight ratio is (2.2-5.0):1; the styrene-based resin is rubber-modified polystyrene resin from Chimei Company, and the MFR is 4-8g / 10min measured at 200°C and 5.0kg load according to ASTM D-1238; The compatibilizer used is Yueyang Petrochemical Company's styrene-ethylene / butylene-styrene (SEBS) block copolymer, YH-500 series linear struct...

Embodiment 2

[0049] The present embodiment is the same as embodiment 1, the difference is:

[0050] The polyphenylene ether polypropylene resin composition of the present embodiment comprises each component of the proportioning shown in Table 1;

[0051] In this example, the compatibilizer used is the styrene-ethylene / butylene-styrene (SEBS) block copolymer of Yueyang Petrochemical Company, YH-600 series four-arm star-shaped structure product, which contains styrene mass The percentage content is 30-35%.

[0052] This embodiment also relates to the preparation method of the aforementioned polyphenylene ether polypropylene resin composition, comprising the following steps:

[0053] (a) Pre-mixing: Mix the polyphenylene ether resin, styrene-based resin and compatibilizer in the ratio shown in Table 1 and add them into a medium-speed mixer. The mixing time is 5-10 minutes, and mix well;

[0054] (b) Add the product of the step (a) into a twin-screw extruder with a temperature of 270-320°C. ...

Embodiment 3

[0056] The polyphenylene ether polypropylene resin composition of the present embodiment comprises each component of the proportioning shown in Table 1;

[0057] In this example, the polypropylene resin used is a crystalline propylene-ethylene block copolymer; the polyphenylene ether resin is obtained by copolymerization of 2,6-dimethylphenol, 2,3,6-trimethylphenol and o-cresol Copolymer; styrene resin is styrene-acrylonitrile copolymer; compatibilizer is methyl styrene-isoprene-methyl styrene block copolymer with star structure.

[0058] This embodiment also relates to the preparation method of the aforementioned polyphenylene ether polypropylene resin composition, comprising the following steps:

[0059] (a) Premixing: Mix the polyphenylene ether resin and compatibilizer in the ratio shown in Table 1 and add them into a medium-speed mixer. The mixing time is 10-15 minutes, and mix well;

[0060] (b) Add the product of the step (a) into a twin-screw extruder with a temperatu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com