Polyester resin for epoxy resin-cured precoated anticorrosive powder coating and preparation method thereof

A technology of epoxy resin curing and powder coating, which is applied in the direction of epoxy resin coating, powder coating, anti-corrosion coating, etc. It can solve the problems of optimization and improvement, no performance, no report on the use of pre-coating powder coating, etc., and achieve anti-corrosion performance Excellent, improved bending resistance, improved damage resistance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The content of the present invention is described in more detail below through the examples, but the following examples are only used to illustrate the content of the present invention, rather than limitation, therefore, any changes within the meaning and scope equivalent to the claims of the present invention, should be considered to be included in the scope of the claims.

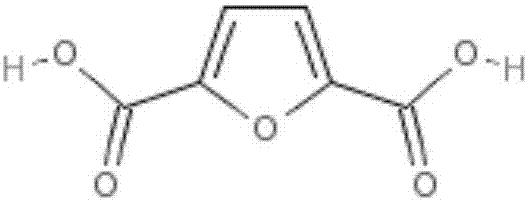

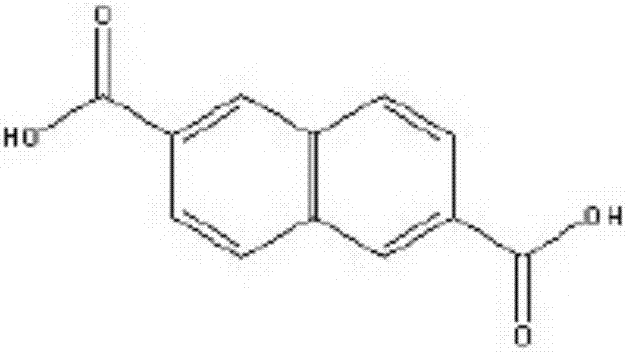

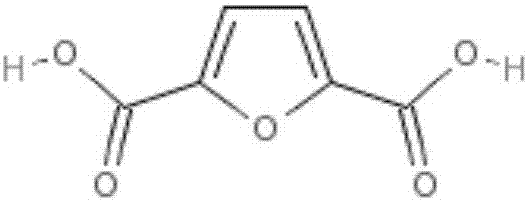

[0026] A polyester resin for epoxy resin curing pre-coating anti-corrosion powder coating, characterized in that it comprises the following components and their mass percentages: polyol: 30-50%; furandicarboxylic acid 5-35%; naphthalene dicarboxylic acid 5- 25%; polybasic acid 5-40%; acidolysis agent 5-20%; catalyst 0.04-0.15%; curing accelerator 0.01-1.0%; / g, a polyester resin with a viscosity of 2500-5000mPa.s, a number-average molecular weight of 2000-4000, and a glass transition temperature of 55-75°C.

[0027] Wherein, the furandicarboxylic acid is 2,5-furandicarboxylic acid, and its chemica...

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com