Abrasion-resistant high-flame-retardance PC material and preparation method thereof

A high flame retardant and wear resistance technology, applied in the field of high wear resistance flame retardant PC materials and their preparation, can solve the problems of poor wear resistance, unsatisfactory materials, deterioration of mechanical properties of materials, etc., to improve mechanical properties , Improve thermal stability, increase the effect of retention length

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

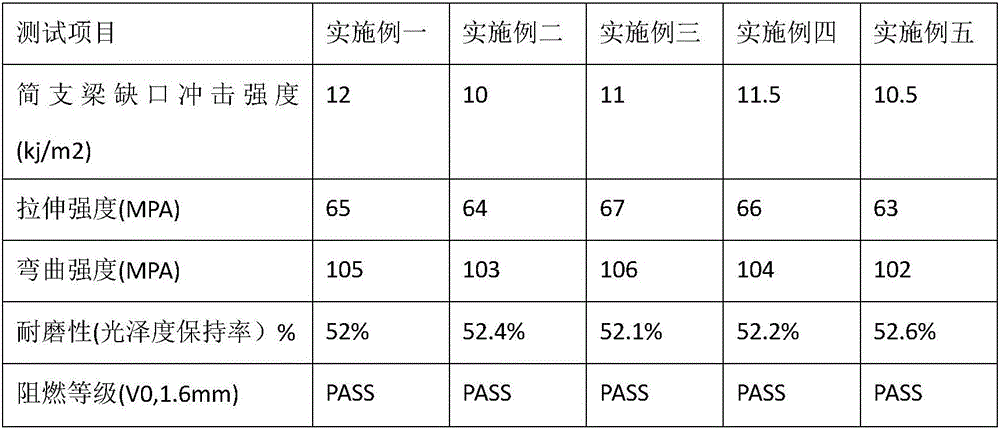

Examples

Embodiment 1

[0033] A wear-resistant and highly flame-retardant PC material, including the following raw materials in weight ratio:

[0034] PC: 80 parts, glass fiber: 10 parts, toughening agent: 3 parts, compatibilizer: 6.5 parts, wear-resistant agent: 3 parts, coupling agent: 0.5 parts, anti-dripping agent: 0.3 parts, flame retardant : 0.5 parts, antioxidant: 1.3 parts, UV absorber: 1 part, lubricant: 0.5 parts.

[0035] Further, the PC is a mixture of different bisphenol A polycarbonates. By mixing different bisphenol A polycarbonates, a polycarbonate mixture with better comprehensive performance is obtained, so that it not only has higher mechanical properties and Thermodynamic properties, but also its high fluidity, good processing performance.

[0036] Further, the glass fiber is an alkali-free glass fiber, the diameter of the glass fiber is 13 μm, the diameter of the glass fiber monofilament is small, the aspect ratio of the glass fiber after shearing is high, and its surface is st...

Embodiment 2

[0052] A wear-resistant and highly flame-retardant PC material, including the following raw materials in weight ratio:

[0053] PC: 75 parts, glass fiber: 8 parts, toughening agent: 1 part, compatibilizer: 8 parts, wear-resistant agent: 4 parts, coupling agent: 0.5 parts, anti-dripping agent: 0.5 parts, flame retardant : 0.2 parts, antioxidant: 0.2 parts, UV absorber: 1 part, lubricant: 0.5 parts.

[0054] Further, the PC is a mixture of different bisphenol A polycarbonates. By mixing different bisphenol A polycarbonates, a polycarbonate mixture with better comprehensive performance is obtained, so that it not only has higher mechanical properties and Thermodynamic properties, but also its high fluidity, good processing performance.

[0055] Further, the glass fiber is an alkali-free glass fiber, the diameter of the glass fiber is 12 μm, the diameter of the glass fiber monofilament is small, the aspect ratio of the glass fiber after shearing is high, and its surface is strict...

Embodiment 3

[0071] A wear-resistant and highly flame-retardant PC material, including the following raw materials in weight ratio:

[0072] PC: 70 parts, glass fiber: 5 parts, toughening agent: 5 parts, compatibilizer: 5 parts, wear-resistant agent: 5 parts, coupling agent: 0.5 parts, anti-dripping agent: 0.6 parts, flame retardant : 0.9 parts, antioxidant: 0.8 parts, UV absorber: 1 part, lubricant: 0.5 parts.

[0073] Further, the PC is a mixture of different bisphenol A polycarbonates. By mixing different bisphenol A polycarbonates, a polycarbonate mixture with better comprehensive performance is obtained, so that it not only has higher mechanical properties and Thermodynamic properties, but also its high fluidity, good processing performance.

[0074] Further, the glass fiber is an alkali-free glass fiber, the diameter of the glass fiber is 14 μm, the diameter of the glass fiber monofilament is small, the aspect ratio of the glass fiber after shearing is high, and its surface is stric...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com