High-impact-resistance PVC profile meeting high-speed extrusion requirement and preparing method thereof

A high-speed extrusion, high-impact technology, applied in the field of high-impact PVC profiles and its preparation, can solve the problems that cannot meet the requirements of high-speed extrusion, etc., to achieve not easy to vulcanize pollution, excellent low-temperature impact resistance, smooth and delicate surface Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

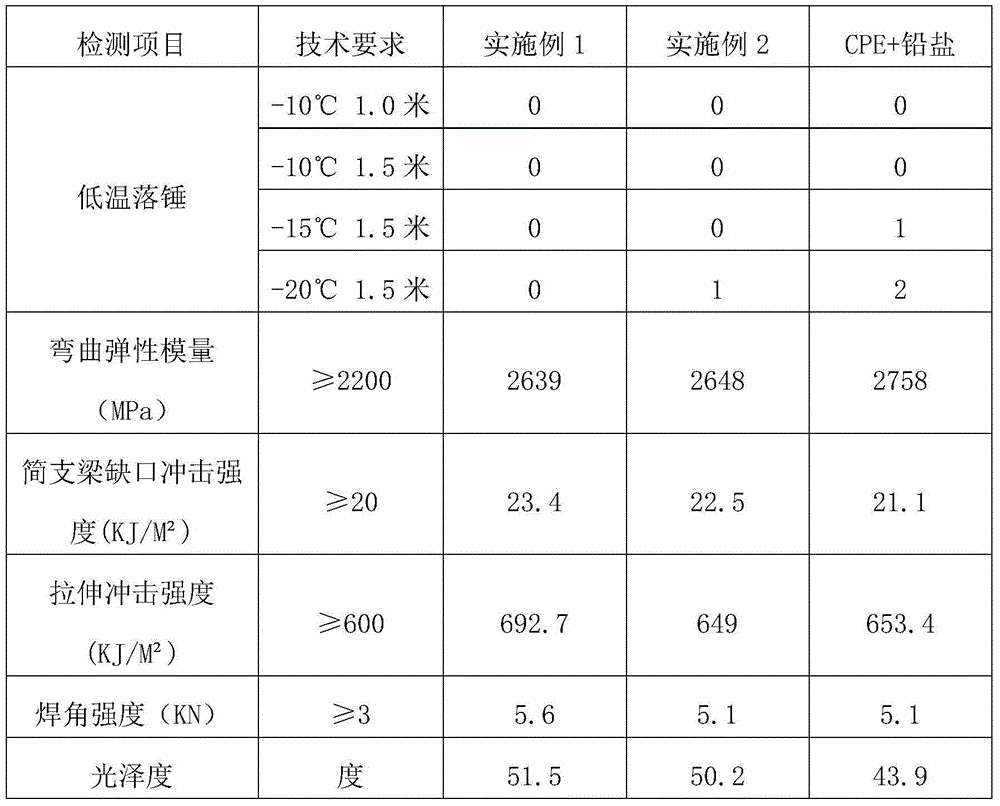

Examples

Embodiment 1

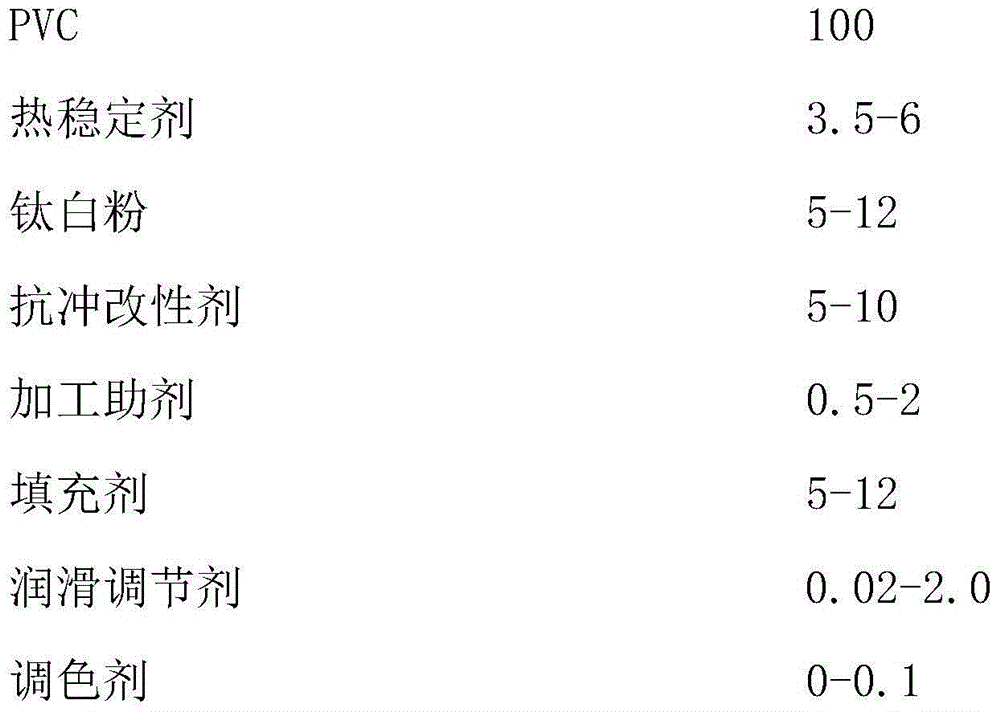

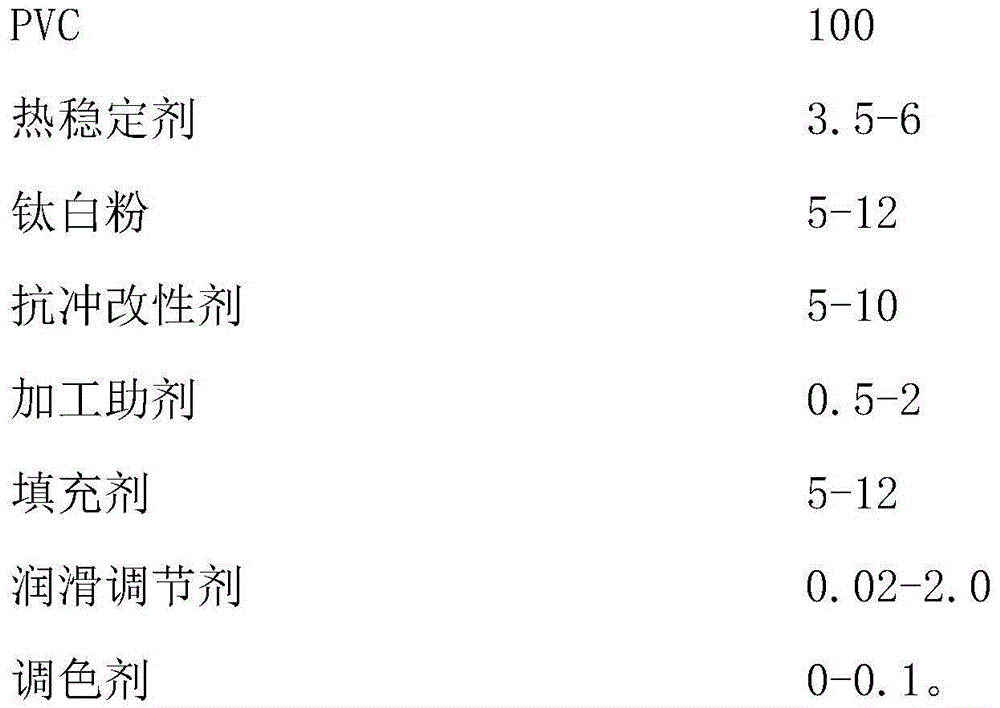

[0041] A high-impact PVC profile satisfying high-speed extrusion, comprising the following substances in parts by weight:

[0042] 100 parts of PVC, 8 parts of titanium dioxide, 10 parts of light calcium carbonate, 7 parts of impact-resistant ACR modifier, 1 part of ACR processing aid acrylate polymer, 3.7 parts of environmentally friendly calcium zinc stabilizer, high-density oxidized polyethylene 0.05 parts of wax, 0.03 parts of ultramarine.

[0043] A preparation method for a high-impact PVC profile meeting high-speed extrusion, comprising the following steps:

[0044] (1) Through the automatic batching system, the required materials are automatically measured according to the above weight parts, and then put into the thermal mixer for mixing. During the thermal mixing process, the moisture in the mixture is fully removed by thermal mixing, and the materials are hot mixed. After mixing in the machine to 120°C, discharge it into the cold mixer, and cold mix to 40°C, remove ...

Embodiment 2

[0047] A high-impact PVC profile satisfying high-speed extrusion, comprising the following substances in parts by weight:

[0048] 100 parts of PVC, 8 parts of titanium dioxide, 10 parts of light calcium carbonate, 6 parts of impact-resistant ACR modifier, 1 part of ACR processing aid acrylate polymer, 3.7 parts of environmentally friendly calcium zinc stabilizer, high-density oxidized polyethylene 0.1 part of wax, 0.03 part of ultramarine blue.

[0049] A preparation method for a high-impact PVC profile meeting high-speed extrusion, comprising the following steps:

[0050] (1) Through the automatic batching system, the required materials are automatically measured according to the above formula ratio, and then put into the thermal mixer for mixing. During the thermal mixing process, the moisture in the mixture is fully removed by thermal mixing, and the materials are thermally mixed. After mixing in the machine to 120°C, it is discharged into a cold mixer, and cold mixed to 45...

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com