Low temperature impact-resistant polypropylene composition

A technology of polypropylene composition and low temperature resistance, which is applied in the field of polypropylene modification, and can solve the problems of insignificant improvement in impact resistance, failure to meet the needs of safe driving of automobiles, and insufficient impact resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

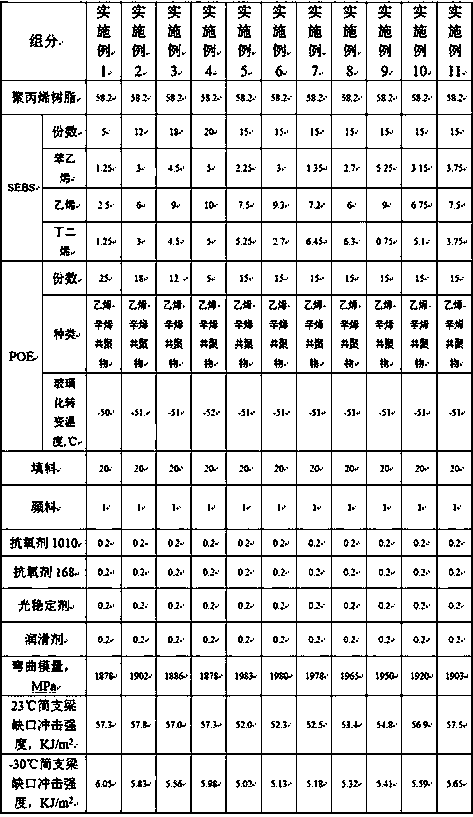

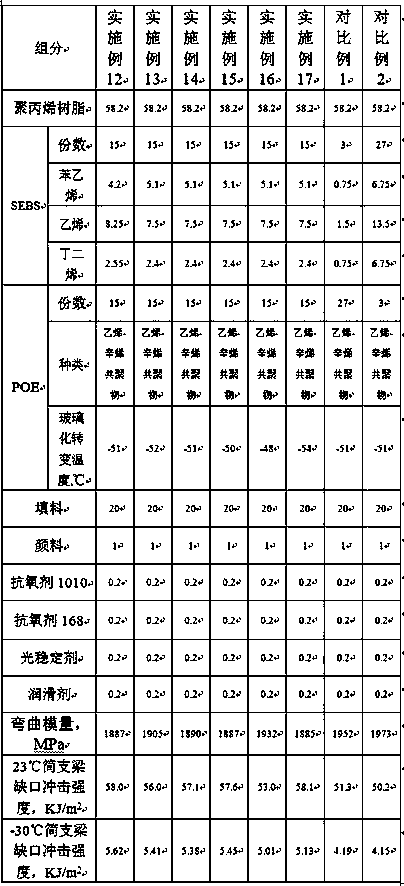

[0022] The following examples will further illustrate the present invention through specific implementation methods. The following examples are preferred trial methods of the present invention, but the implementation methods of the present invention are not limited by the following examples.

[0023] raw material

[0024] Polypropylene resin, copolymerized polypropylene resin, PP BX3800, produced by SK Company in South Korea, with a melt mass flow rate of 28.4 g / 10min at 190°C and a load of 2.16 Kg according to ISO1133 standard;

[0025] Hydrogenated styrene-butadiene block copolymer SEBS, produced by Kraton;

[0026] Polyolefin elastomer POE with a melt mass flow rate of 1 g / 10min and a density of 0.87 g / cm 3 :

[0027] Ethylene-octene copolymer, produced from Dow company;

[0028] Filler, talcum powder TYT-777A, produced by Beihai Group;

[0029] Pigment, carbon black M717, produced by CABOT company;

[0030] Antioxidant: hindered phenolic antioxidant 1010, phosphite an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melt mass flow rate | aaaaa | aaaaa |

| Melt mass flow rate | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com