Low-temperature impact resistant, cracking resistant and flame-retardant polypropylene material, and preparation method and applications thereof

A technology of flame-retardant polypropylene and low-temperature resistance, which is applied in the application field of automotive exterior decoration and functional parts. It can solve the problems of poor low-temperature impact resistance, poor low-temperature impact performance, and insufficient notch impact strength, etc., and achieve good low-temperature impact resistance. Ability, improved crack resistance, better toughening effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

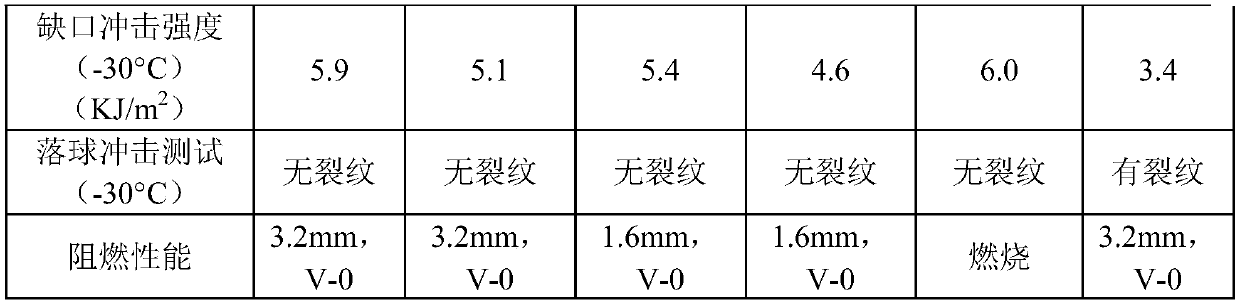

Examples

Embodiment 1

[0040] A low-temperature impact-resistant, crack-resistant, and flame-retardant polypropylene material, comprising the following components in parts by weight: 71.2 parts of polypropylene resin, 7 parts of POE, 15 parts of decabromodiphenylethane, 5 parts of antimony white, 0.8 parts of stabilizer, 1 part of toner.

[0041] The preparation method of the above-mentioned low-temperature impact-resistant, crack-resistant and flame-retardant polypropylene material is as follows: each component is placed in a high-speed mixer and fully stirred to obtain a premix, and the premix is added to the main feeding port of the twin-screw extruder, Melt extrusion, granulation and drying are carried out to obtain a low-temperature impact-resistant, crack-resistant, and flame-retardant polypropylene material.

[0042] Among them, the melt extrusion temperature of the twin-screw extruder is: the temperature of the first zone is 100-120°C, the temperature of the second zone is 190-210°C, the t...

Embodiment 2

[0044] A low-temperature impact-resistant, crack-resistant, flame-retardant polypropylene material, comprising the following components in parts by weight: 61.2 parts of polypropylene resin, 7 parts of POE, 10 parts of talcum powder, 15 parts of decabromodiphenylethane, 5 parts of antimony white, 0.8 parts of stabilizer, 1 part of toner.

[0045] The preparation method of the above-mentioned low-temperature impact-resistant, crack-resistant and flame-retardant polypropylene material is as follows: each component is placed in a high-speed mixer and fully stirred to obtain a premix, and the premix is added to the main feeding port of the twin-screw extruder, Melt extrusion, granulation and drying are carried out to obtain a low-temperature impact-resistant, crack-resistant, and flame-retardant polypropylene material.

[0046] Among them, the melt extrusion temperature of the twin-screw extruder is: the temperature of the first zone is 100-120°C, the temperature of the second z...

Embodiment 3

[0048]A low-temperature impact-resistant, crack-resistant, flame-retardant polypropylene material, comprising the following components in parts by weight: 60.2 parts of polypropylene resin, 10 parts of POE, 21 parts of decabromodiphenylethane, 7 parts of antimony white, 0.8 parts of stabilizer, 1 part of toner.

[0049] The preparation method of the above-mentioned low-temperature impact-resistant, crack-resistant and flame-retardant polypropylene material is as follows: each component is placed in a high-speed mixer and fully stirred to obtain a premix, and the premix is added to the main feeding port of the twin-screw extruder, Melt extrusion, granulation and drying are carried out to obtain a low-temperature impact-resistant, crack-resistant, and flame-retardant polypropylene material.

[0050] Among them, the melt extrusion temperature of the twin-screw extruder is: the temperature of the first zone is 100-120°C, the temperature of the second zone is 190-210°C, the tempe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| impact strength | aaaaa | aaaaa |

| impact strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com