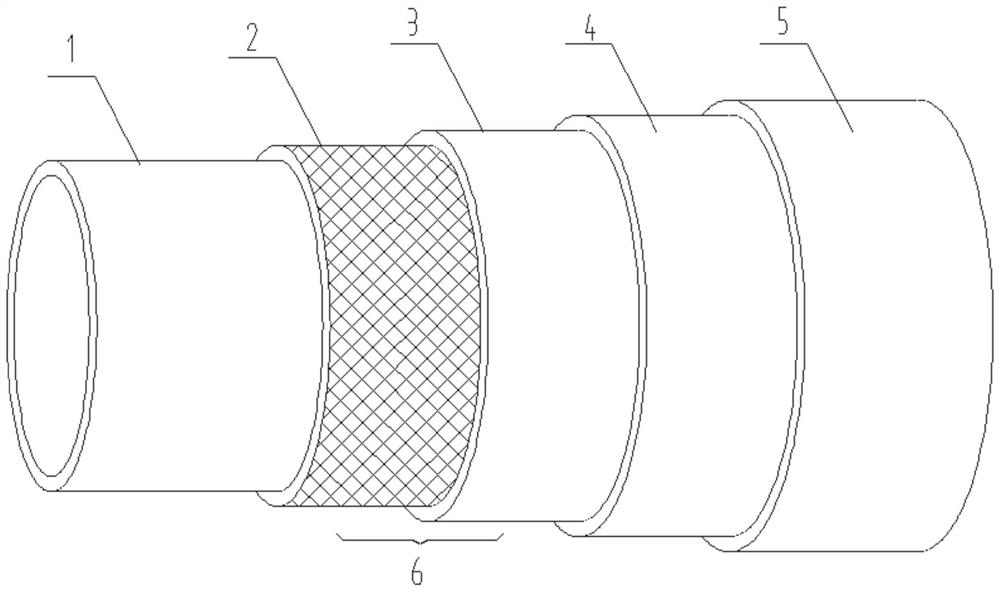

Steel wire mesh framework reinforced polypropylene composite pipe and preparation method and application of steel wire mesh framework reinforced polypropylene composite pipe

A technology of polypropylene and steel wire mesh, applied in the direction of pipe, rigid pipe, pipeline protection, etc., can solve the problems of poor heat resistance, high brittleness of polypropylene matrix, etc., to solve low-temperature brittleness, improve low-temperature impact resistance, and low-temperature resistance sexually effective effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

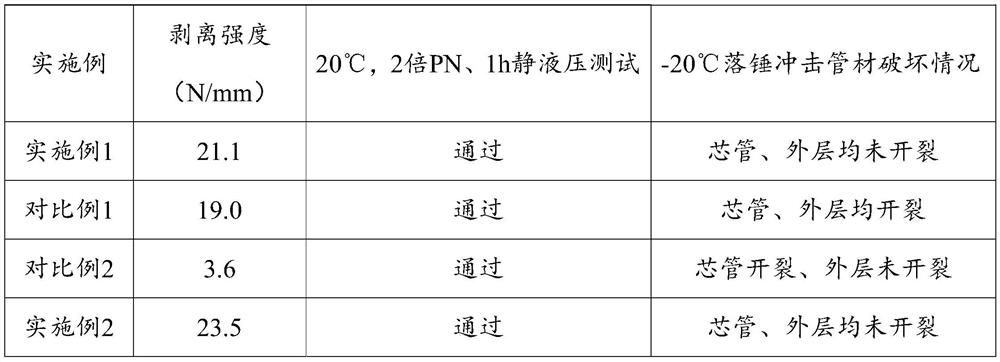

Embodiment 1

[0052] The first bonding resin formula: 25 parts of maleic anhydride grafted polypropylene;

[0053] Polypropylene: 59.7 parts;

[0054] Toughening agent: 10 parts;

[0055] Adhesion regulator: 5 parts;

[0056] Anti-aging additives: 0.3 parts;

[0057] The second bonding resin formula: ethylene octene copolymer: 59.5 parts;

[0058] Polypropylene: 20 parts;

[0059] Polyethylene: 20 parts;

[0060] Anti-aging additives: 0.5 parts;

[0061] S1 Polypropylene core pipe extrusion: Extrude polypropylene core pipe through pipe processing equipment, and the extrusion temperature of the pipe is 180°C;

[0062] S2 steel wire winding: on the core tube, a layer of steel wire is wound left-handed, and then a layer of steel wire is wound right-handed. The winding angle of the steel wire is 54.5°;

[0063] S3 Extrusion of the first adhesive resin layer: extrude the first adhesive resin on the winding steel wire layer, the thickness of the first adhesive resin layer is preferably to ...

Embodiment 2

[0085] First bonding resin formulation:

[0086] Maleic anhydride grafted polypropylene: 40 parts;

[0087] Polypropylene: 44.5 parts;

[0088] Toughening agent: 5 parts;

[0089] Adhesion regulator: 10 parts;

[0090] Anti-aging additives: 0.5 parts;

[0091] Second bonding resin formulation:

[0092] Ethylene octene copolymer: 69.5 parts;

[0093] Polypropylene: 10 parts;

[0094] Polyethylene: 20 parts;

[0095] Anti-aging additives: 0.5 parts;

[0096] S1 Polypropylene core pipe extrusion: Extrude polypropylene core pipe through pipe processing equipment, and the extrusion temperature of the pipe is 195°C;

[0097] S2 Winding of the first two layers of steel wire and extrusion of the first adhesive resin layer: First, a layer of steel wire is wound left-handed on the core tube, and then a layer of steel wire is wound right-handed. The winding angle of the steel wire is 54.5°; extrude on the wound steel wire layer The first adhesive resin is produced, the thickness...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com