Novel polyamide adhesive

A polyamide hot-melt adhesive, dimerized amine technology, used in adhesives, other chemical processes, chemical instruments and methods, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] With 0.5 mole of sebacic acid, 0.25 mole of dipolyamine (Priamine1074, British Croda Company), 0.05 mole of hexamethylenediamine, 0.125 mole of piperazine, 0.075 mole of polytetramethylene ether diamine (THF-100) and 0.3g Put the antioxidant 1010 into a 1000ml four-necked flask, and raise the temperature to 160°C under the protection of nitrogen; after the components in the bottle are completely dissolved, start to raise the temperature slowly. Raise the temperature to 240°C within 1.5-2 hours; measure the water output; when it reaches more than 80% of the theoretical water output, gradually reduce the pressure; finally complete the entire reaction under high vacuum, and the vacuum reaction time is about 5-10 hours. Then pressurize to normal pressure with nitrogen and stir for half an hour. Finally, pour the polyamide on the surface of the PTFE board while it is hot, cool it and cut it into particles.

[0052] The obtained polyamide hot melt adhesive has a ring and bal...

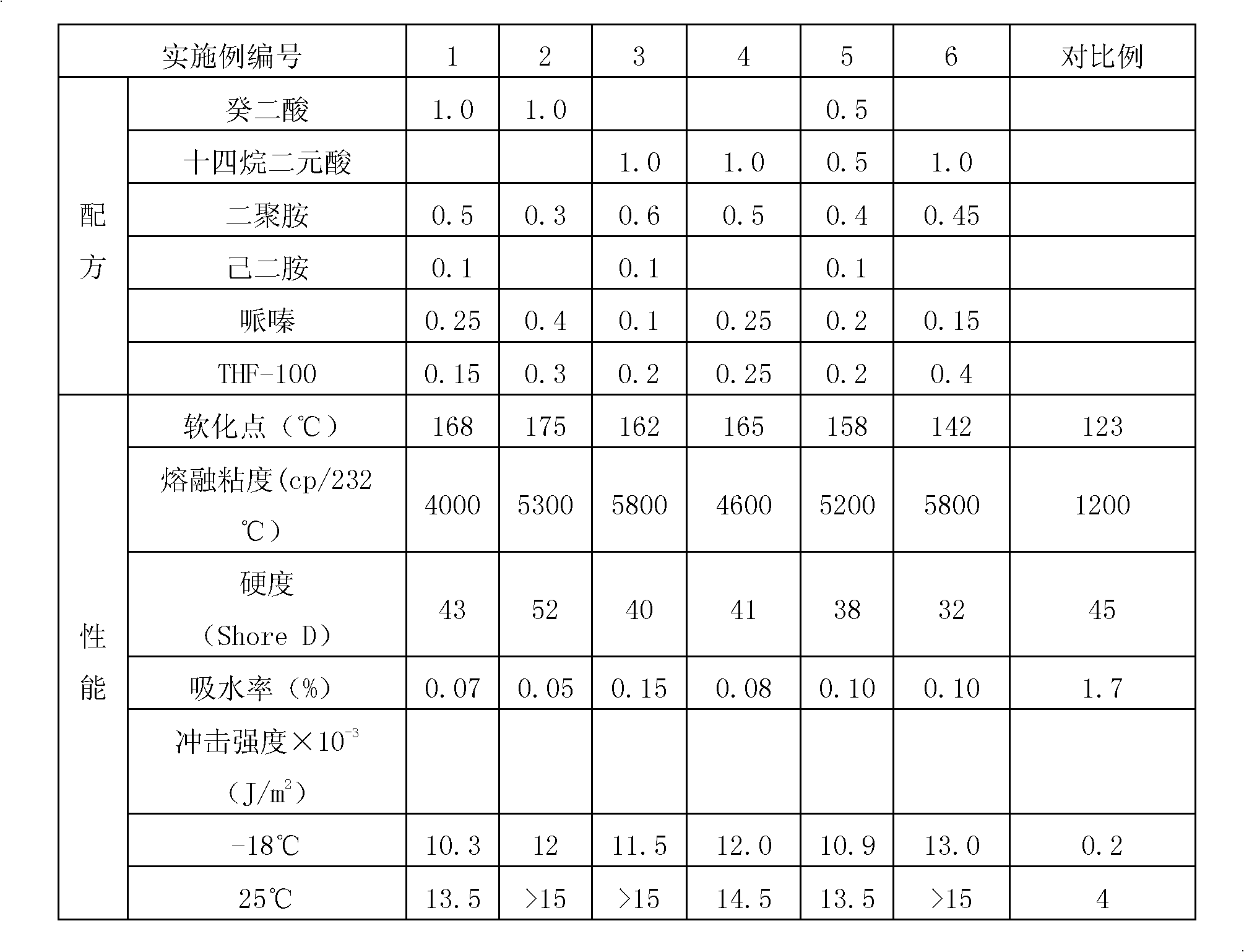

Embodiment 2~6

[0054] Examples 2-6 refer to the formulations in Table 1 and the above synthesis process to obtain polyamide products.

PUM

| Property | Measurement | Unit |

|---|---|---|

| amine value | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com