Extrusion type solar backboard and preparing method thereof

A technology of solar backsheet and extrusion type, which is applied in the direction of chemical instruments and methods, other household appliances, electrical components, etc., and can solve the problem of low interlayer adhesion, low low temperature impact resistance, and poor low temperature impact resistance of solar backsheets. sexual issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

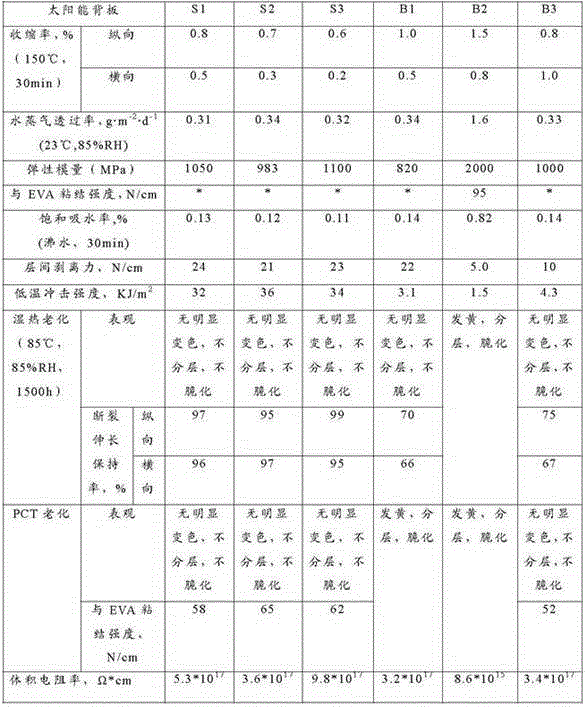

Examples

Embodiment 1

[0064] An extruded solar backboard, the backboard has a three-layer structure of inner layer / middle layer / outer layer;

[0065] (1) Inner layer structure: Add 10 parts of titanium dioxide R960 (DuPont, USA) and 0.3 parts of silane coupling agent 3-aminopropyltriethoxysilane KH550 (Danyang Organic Silicon Material Industry Co., Ltd.) into the high mixer In, stirring for 30 minutes, the rotating speed is 600 rev / min, to obtain the filler pretreated by silane coupling agent; 0.923 g / cm 3 , DSC melting point is 110°C, melt flow rate of 190°C / 2.16 kg is 1.8 g / 10 min), 33 parts of homopolypropylene 1300 (Beijing Yanshan Petrochemical Company, its DSC melting point is 160°C, 230°C / 2.16 kg The melt flow rate is 1.5 g / 10 min), 0.1 part of antioxidant tetrakis [β-(3', 5'-di-tert-butyl-4'-hydroxyphenyl) propionate] pentaerythritol ester (Beijing Addition Auxiliaries Research Institute, KY1010), 0.2 parts of UV absorber 2-hydroxy-4-n-octyloxybenzophenone (Beijing Addition Auxiliaries Re...

Embodiment 2

[0070] An extruded solar backboard, the backboard has an inner / outer two-layer structure;

[0071](1) Inner layer structure: 10 parts of titanium dioxide R960, 10 parts of talc powder (Lingshou County Shunxin Mineral Products Processing Factory) and 0.3 parts of silane coupling agent 3-glycidyl etheroxypropyltrimethoxysilane KH560 ( Danyang Organosilicon Material Industry Co., Ltd.) was added into a high mixer, stirred for 30 minutes at a speed of 600 rpm to obtain a filler pretreated by a silane coupling agent; then the filler pretreated by the above silane coupling agent was mixed with 34 parts of linear Low-density polyethylene LLDPE7042 (Sinopec Yangzi Petrochemical Co., Ltd., with a density of 0.918 g / cm 3 , DSC melting point is 121°C, melt flow rate of 190°C / 2.16 kg is 2 g / 10 min), 33 parts of random copolymerized polypropylene R370Y (Korean SK Group, its DSC melting point is 164°C, 230°C / 2.16 kg The melt flow rate is 18 g / 10 min), 33 parts of block copolymer polypropyl...

Embodiment 3

[0075] An extruded solar backboard, the backboard has a three-layer structure of inner layer / middle layer / outer layer;

[0076] (1) Inner layer structure: 10 parts of titanium dioxide R960, 10 parts of talc powder, 10 parts of sericite powder GA5 (Chuzhou Gray Mining Co., Ltd.) and 0.3 parts of silane coupling agent 3-aminopropyltriethoxysilane Add KH550 into a high mixer, stir for 30 minutes at a speed of 600 rpm to obtain a filler pretreated with a silane coupling agent; Segment copolymerized polypropylene K8303, 0.1 part of antioxidant tetrakis [β-(3', 5'-di-tert-butyl-4'-hydroxyphenyl) propionate] pentaerythritol ester, 0.2 part of ultraviolet absorber 2-hydroxy-4 -N-octyloxybenzophenone, 0.2 parts of light stabilizer bis(2,2,6,6-tetramethyl-4-piperidinyl) sebacate, mixed uniformly; The material is put into the A screw of the three-layer co-extrusion sheet unit, the screw diameter is 75 mm, and the aspect ratio is 33;

[0077] (2) Intermediate layer structure: Add 10 par...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Melting point | aaaaa | aaaaa |

| The melt flow rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com