Production method of red mud complexed polyvinyl chloride colorized rigid plastic

A polyvinyl chloride and rigid plastic technology, applied in chemical instruments and methods, layered products, synthetic resin layered products, etc., can solve monotony, can not solve the color, it is difficult to ensure the stability of red mud plastic silver gray, etc. problems, to achieve the effect of improving compatibility, improving tensile toughness and low temperature impact resistance, and colorful colors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

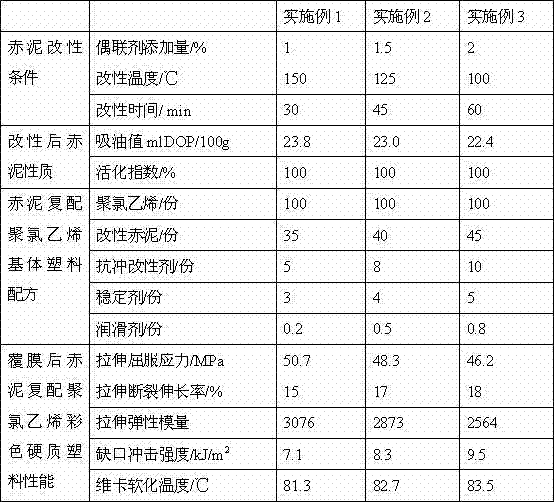

[0030] Using dry red mud from a domestic alumina plant as raw material, it is classified into two parts: +800 mesh and -800 mesh through air classifier. -800 mesh red mud is modified with polyvinyl chloride, impact modifier, stabilizer The modified red mud compound polyvinyl chloride color rigid plastic is obtained by high-speed mixing of agent and lubricant, melt extrusion and surface coating treatment. The formula composition content, processing conditions and technical performance indexes of each embodiment are shown in Table 1.

[0031] Table 1 formula composition content, processing condition and technical performance index of each embodiment of the present invention

[0032]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com