Low-temperature impact resistance PP-R tubing and preparation method thereof

A low-temperature impact-resistant, PP-R technology, applied in the field of PP-R pipe and its preparation, can solve the problem that the internal pressure resistance of the pipe decreases, the content of PP-B material is high, and the mixture of PP-R material and PP-B material is not good. Very uniform and other problems, to achieve the effect of good internal pressure resistance and improved low temperature impact resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

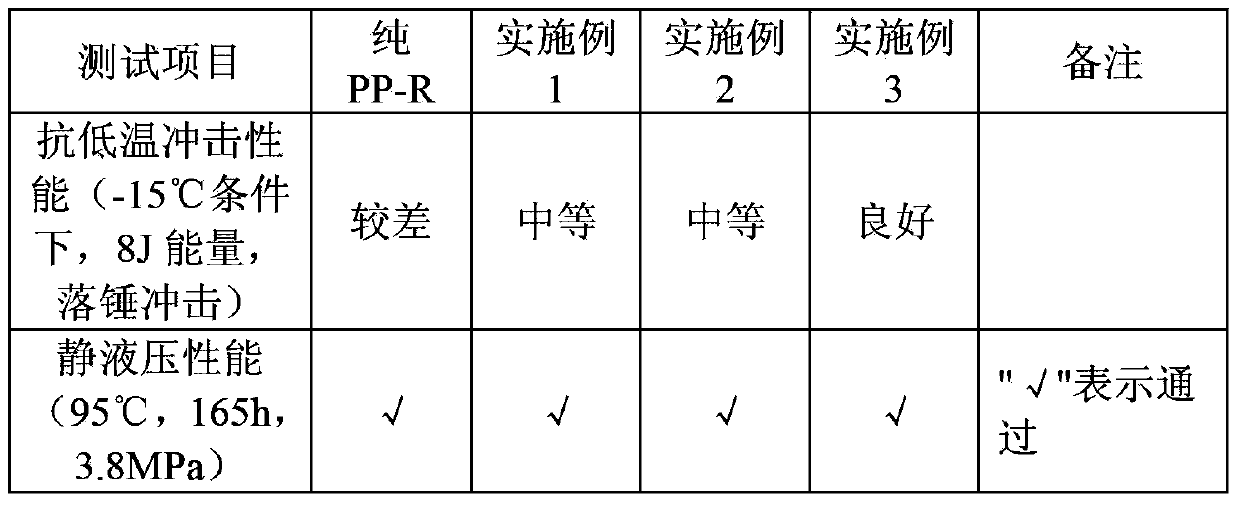

Embodiment 1

[0033] Take 90kg random copolymerized polypropylene powder, 9.5kg block copolymerized polypropylene powder, 0.3kg N,N'-dicyclohexyl-2,6-naphthalene dicarboxamide β crystal nucleating agent, and other processing aids (Auxiliaries commonly used in this field are generally antioxidants and lubricants. According to the actual addition, the addition amount should not exceed 0.3%, the same as the following examples.) Stir in a mixer for 5 minutes. The mixture is extruded and granulated in a twin-screw extruder at 190° C. to prepare a composite material, and then the composite material is extruded at 190° C. to form a low-temperature impact-resistant pipe.

Embodiment 2

[0035] Take 80kg random copolymerized polypropylene powder, 19.5kg block copolymerized polypropylene powder, 0.5g group IIa beta crystal nucleating agent (composite ratio of calcium stearate and pimelic acid 1:1), other processing Auxiliary, stir in the mixer for 5min. The mixture is extruded and granulated in a twin-screw extruder at 200°C to prepare a composite material, and then the composite material is extruded at 200°C to form a low-temperature impact-resistant pipe.

Embodiment 3

[0037] Take 70kg of random copolymerized polypropylene powder, 29kg of block copolymerized polypropylene powder, 1kg of lanthanide mononuclear metal compound β crystal form nucleating agent, and other processing aids, and stir in a mixer for 5 minutes. The mixture is extruded and granulated in a twin-screw extruder at 220°C to prepare a composite material, and then the composite material is extruded at 220°C to form a low-temperature impact-resistant pipe.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com