Supernylon 6 alloy and method for prearing supernylon 6 alloy by means of in-situ reaction compatibilization

A nylon and super-tough technology, applied in the field of super-tough nylon 6 alloy, can solve problems such as poor mechanical properties of blends, and achieve the effects of easy popularization and application, high notched impact strength and low water absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

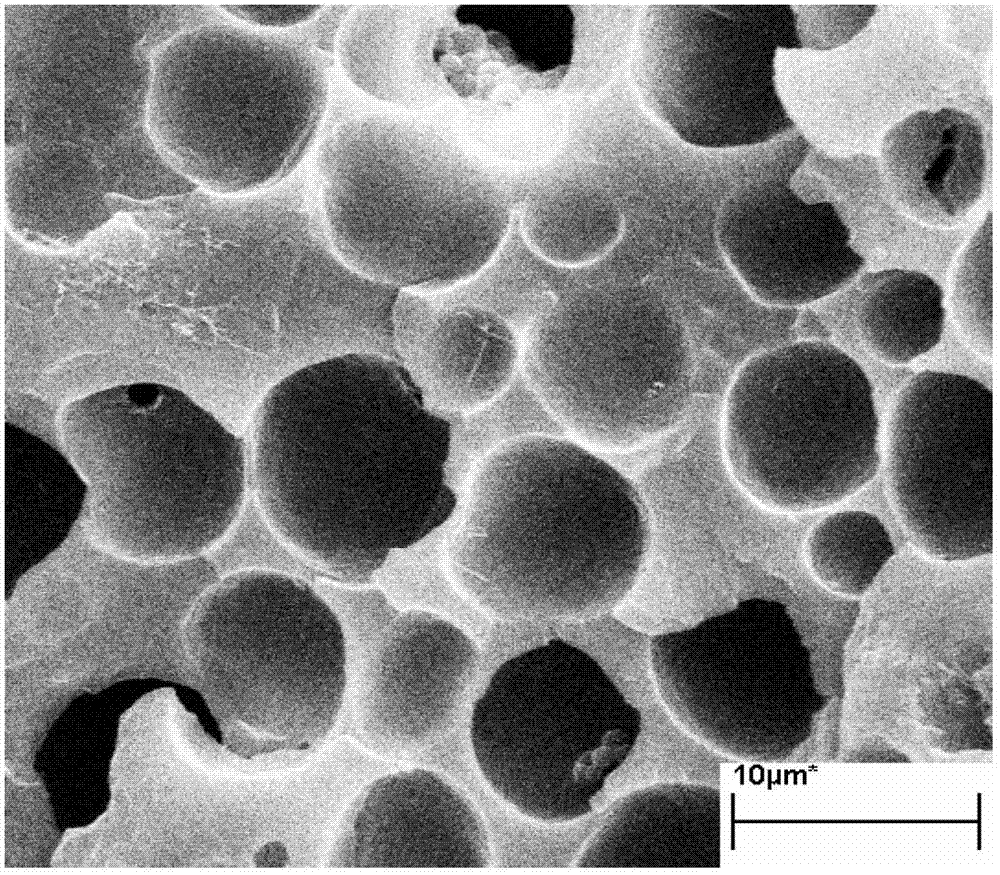

Embodiment 1

[0049] The super-tough nylon 6 alloy prepared by the in-situ reaction compatibilization method is blended with the following raw materials: 90 parts by weight of nylon 6 (PA6), 10 parts of ethylene and octene copolymer (POE), 2,5-dimethyl- 2,5-Di-tert-butylperoxyhexane (L-101) 0.1 part, maleic anhydride (MAH) 1 part, high density polyethylene grafted maleic anhydride (HDPE-g-MAH) 2 parts.

[0050] The method for preparing super-tough nylon 6 alloy by in-situ reaction compatibilization method includes the following steps:

[0051] (1) Dissolve the initiator 2,5-dimethyl-2,5-di-tert-butylperoxide hexane and maleic anhydride in acetone, and place it for later use;

[0052] (2) Put nylon 6 in a vacuum oven for drying treatment, control the oven temperature at 90°C for 4 hours, and place the POE in a vacuum oven for drying treatment, control the oven temperature at 70°C for 4 hours, Then cool nylon 6 and POE to room temperature;

[0053] (3) Mix the dried nylon 6 and POE uniformly in the ...

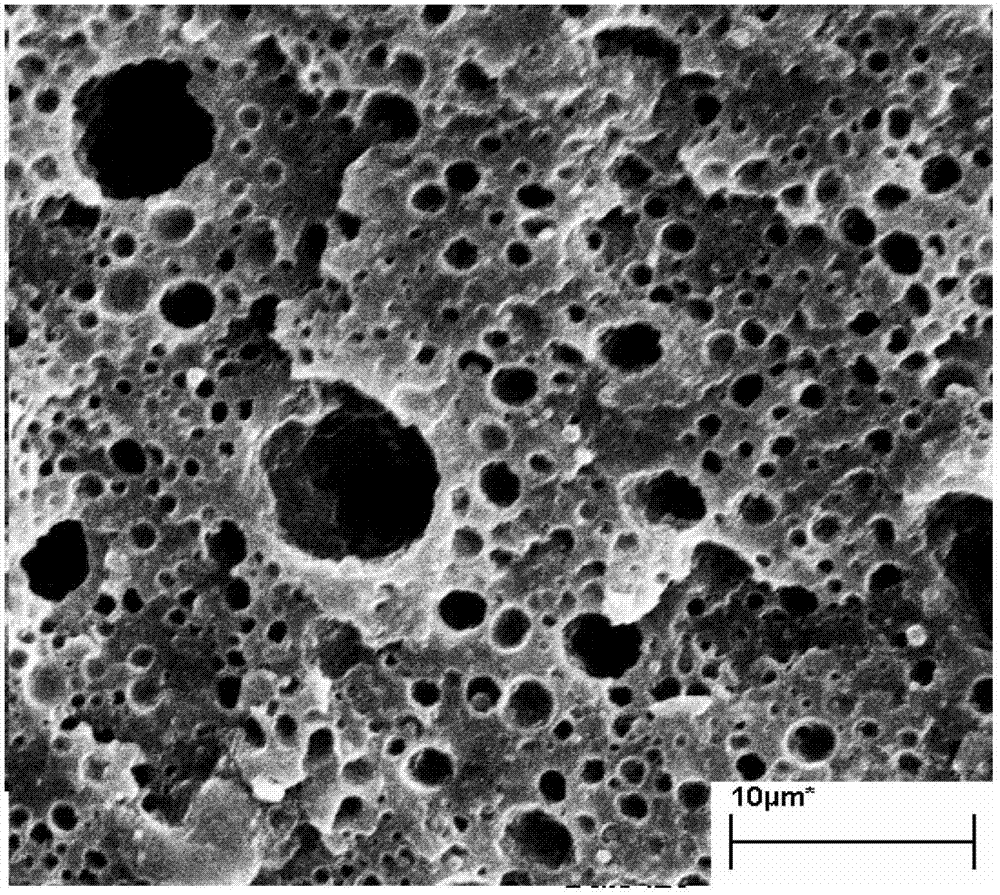

Embodiment 2

[0056] The super-tough nylon 6 alloy prepared by in-situ reaction compatibilization method is blended with the following raw materials by weight: 80 parts of nylon 6 (PA6), 20 parts of ethylene and octene copolymer (POE), 2,5-dimethyl- 2,5-Di-tert-butylperoxyhexane (L-101) 0.1 part, maleic anhydride (MAH) 1 part, high density polyethylene grafted maleic anhydride (HDPE-g-MAH) 2 parts.

[0057] The method for preparing super-tough nylon 6 alloy by in-situ reaction compatibilization method is the same as that in Example 1.

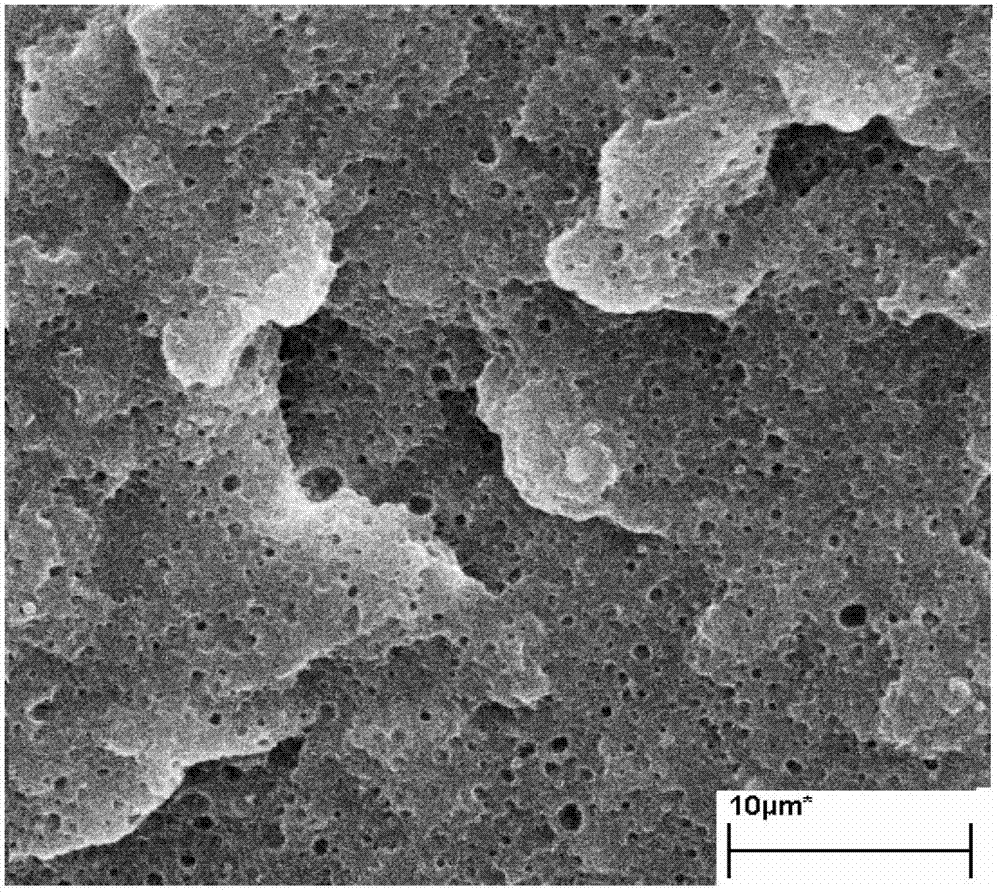

Embodiment 3

[0059] The super-tough nylon 6 alloy prepared by the in-situ reaction compatibilization method is blended with the following raw materials: 70 parts by weight of nylon 6 (PA6), 30 parts of ethylene and octene copolymer (POE), 2,5-dimethyl- 2,5-Di-tert-butylperoxyhexane (L-101) 0.1 part, maleic anhydride (MAH) 1 part, high density polyethylene grafted maleic anhydride (HDPE-g-MAH) 2 parts.

[0060] The method for preparing super-tough nylon 6 alloy by in-situ reaction compatibilization method is the same as that in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com