Method for synthesizing water-dispersion organosilicon-polyurethane block copolymer

A block copolymer, silicone technology, applied in polyurea/polyurethane coatings, devices for coating liquid on surfaces, coatings, etc., can solve the problem of low reactivity, poor hydrolysis resistance, and low molecular weight of silane coupling agents problem, to achieve the effect of broad application prospects, good stability and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Synthesis of prepolymers:

[0031] Add toluene diisocyanate, polyoxypropylene ether diol (hydroxyl value = 105 to 117), castor oil, dimethylol propionic acid and a small amount of solvent in sequence according to the proportion given in Table 2. In a four-neck flask with a thermometer, a thermometer, and a nitrogen pipe, react at 60-70°C for about 3 hours, and when the free NCO reaches a predetermined value, lower the temperature to stop the reaction, and the isocyanate-terminated polyurethane prepolymer is obtained. The preparation of the prepolymer can also be prepared by a stepwise reaction, that is, TDI and N 210 , Castor oil reacted for about 3 hours under the above conditions, and then reacted with DMPA to obtain a water-dispersible anionic polyurethane prepolymer

[0032] Table 2. Raw material ratio for preparing water-dispersed silicone-modified polyurethane with different chain extenders (unit: mmol)

[0033] raw material

HDA

602

NS840 ...

Embodiment 2

[0051] Embodiment 2. reaction conditions and raw material proportioning are the same as embodiment 1. The effect of castor oil and its content on the water resistance of water-dispersed silicone-polyurethane block copolymer film-formers was investigated by changing the feed ratio of polyoxypropylene ether glycol and castor oil.

[0052] Table 7. Effect of castor oil content on the water resistance of water-dispersed silicone block polyurethane film-formers

[0053] Castor Oil and N 210

[0054] Note: The carboxyl content in the copolymer = 2.0%; the number average molecular weight of the chain extender NS is 1090; when castor oil and N 210 When the molar ratio of the castor oil is 0-0.16, the water absorption decreases with the prolongation of the soaking time, which is caused by the low content of castor oil, poor water resistance, and the loss of weight in the sample.

Embodiment 3

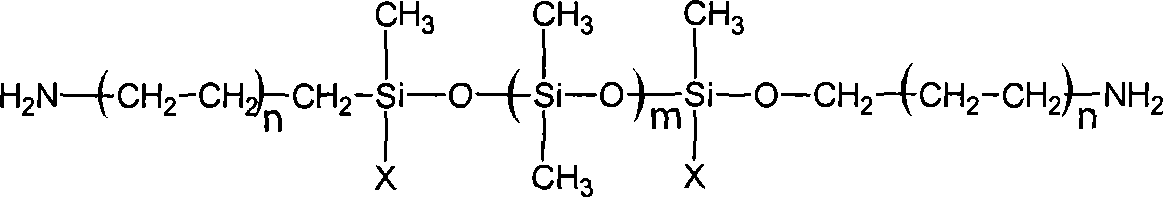

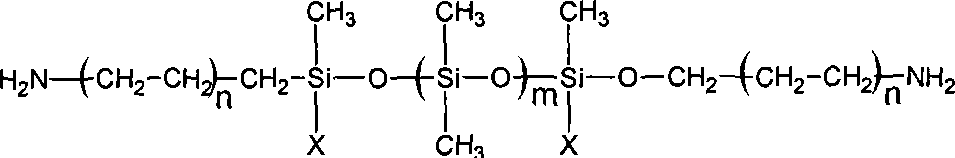

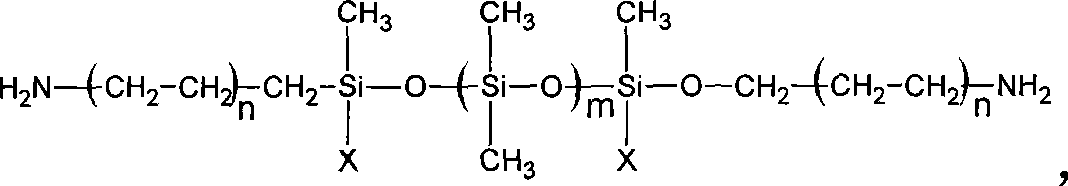

[0055] Example 3. Effect of block density and block length on the film performance of silicone-polyurethane block copolymer emulsion

[0056] The synthesis process is the same as in Example 1. The molar ratio of castor oil to polyoxypropylene ether glycol is 0.25, and the carboxyl content of the copolymer is 2.0%, and the molecular chain length and block density of the aminoalkyl polysiloxane oligomer of the chain extender are changed to investigate its dispersion in water. Effect of silicone-polyurethane block copolymer film formers on water resistance and mechanical properties. The ratio of raw materials is shown in Table 8 and Table 9.

[0057] Table 8. Raw material ratio of water-dispersed silicone-polyurethane block copolymers with different silicone block contents (unit: mmol)

[0058]

[0059] Note: The molecular weight of aminoalkylsiloxane oligomer NS is 1090

[0060] Table 9. Raw material ratio of silicone-polyurethane block copolymer emulsions with different s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com