Ultrahigh-strength active powder concrete and preparation method thereof

A technology of active powder and concrete, which is applied in the direction of climate sustainability, sustainable waste treatment, solid waste management, etc., can solve the problems of compressive and flexural strength that cannot meet ultra-high compressive strength, and achieve improved flexural and Compressive strength, best durability and shear stability, effect of high compressive strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

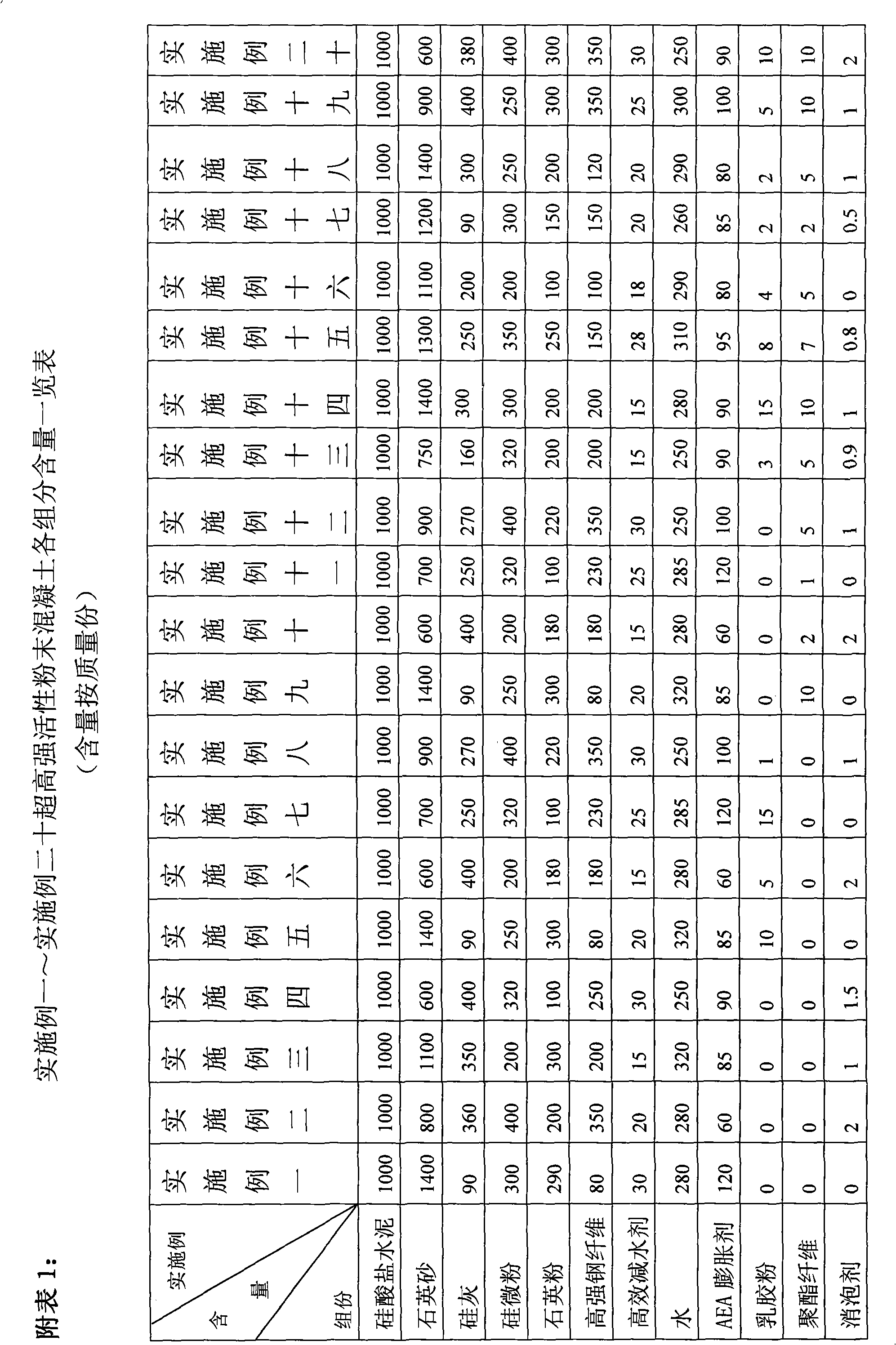

[0046] An ultra-high-strength reactive powder concrete and a manufacturing method thereof. The ultra-high-strength reactive powder concrete is composed of the following raw materials mixed. In the mixture, the content of each component is calculated as:

[0047] 1000 parts of 42.5 Portland cement, 1400 parts of 20-100 mesh quartz sand, SiO 2 ≥95% silica fume 90 parts, 1500 mesh silica powder 300 parts, 300 mesh quartz powder 290 parts, high strength steel fiber 80 parts, superplasticizer 30 parts, water 280 parts, AEA expansion agent 120 parts.

[0048] The production method is: prepare the above-mentioned components in proportion, first pour the high-efficiency water reducer and water into the mixer at the same time and stir for about 1 minute to make them uniform, and then mix the remaining materials - cement, quartz sand, silica fume , microsilica powder, quartz powder, AEA expansion agent, defoamer and other materials are poured into the mixer, stirred evenly to form a pas...

Embodiment 5 Embodiment 8

[0052] An ultra-high-strength reactive powder concrete and its manufacturing method, its main components and manufacturing method are basically the same as in Example 1, the difference is that latex powder is added to the components of the ultra-high-strength reactive powder concrete, each component The content is calculated as:

[0053] Portland cement 1000 parts, quartz sand 600-1400 parts,

[0054] 90-400 parts of silica fume, 200-400 parts of silica powder,

[0055] 100-300 parts of quartz powder, 80-350 parts of high-strength steel fiber,

[0056] 15-30 parts of superplasticizer, 250-320 parts of water,

[0057] 60-120 parts of AEA expansion agent, 1-15 parts of latex powder,

[0058] 0-2 parts of defoamer.

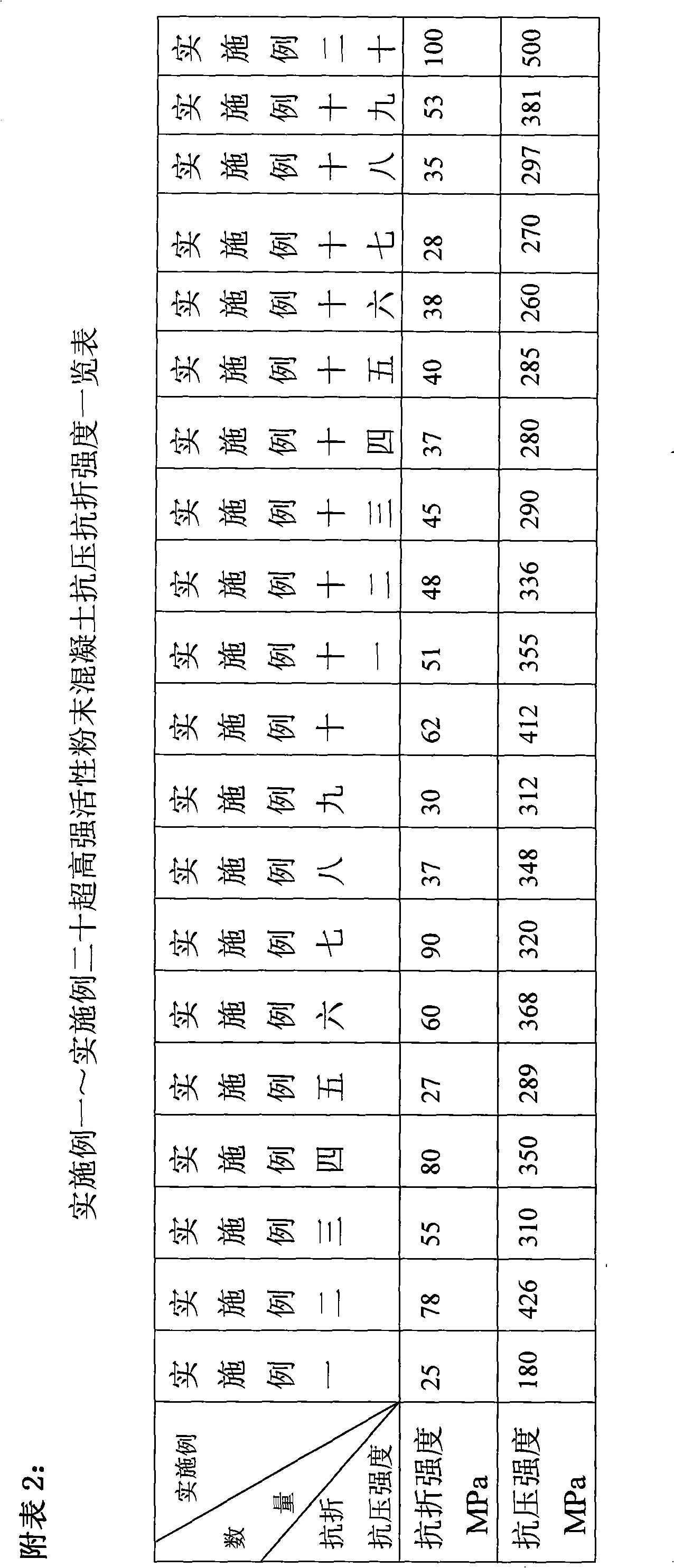

[0059] For the specific components of each embodiment, please refer to the attached table 1: "Example 1-Example 20 Ultra-high-strength reactive powder concrete component content list", the data of Example 51-Example 8.

[0060] The flexural strength of the ultra...

Embodiment 9 Embodiment 12

[0062] An ultra-high-strength reactive powder concrete and a manufacturing method thereof, its main components and manufacturing method are basically the same as in Example 1, the difference is that polyester fibers are added to the components of the ultra-high-strength reactive powder concrete, and each group Parts content is calculated as:

[0063] Portland cement 1000 parts, quartz sand 600-1400 parts,

[0064] 90-400 parts of silica fume, 200-400 parts of silica powder,

[0065] 100-300 parts of quartz powder, 80-350 parts of high-strength steel fiber,

[0066] 15-30 parts of superplasticizer, 250-320 parts of water,

[0067] 60-120 parts of AEA expansion agent, 1-10 parts of polyester fiber,

[0068] 0-2 parts of defoamer.

[0069] For the specific components of each embodiment and the flexural strength and compressive strength of the manufactured ultra-high-strength reactive powder concrete, please refer to the data of Examples 9 to 12 in Attached Table 1 and Attache...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Flexural strength | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

| Flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com