IXPE electron radiation on crosslinking polyethylene conductive foam and preparation method thereof

A technology of cross-linked polyethylene and conductive foam, which is applied in the field of IXPE electronic radiation cross-linked polyethylene conductive foam and its preparation, can solve the problems of poor comprehensive performance of conductive foam, and achieve excellent surface quality, fine and uniform cells , The effect of long-term stability of conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

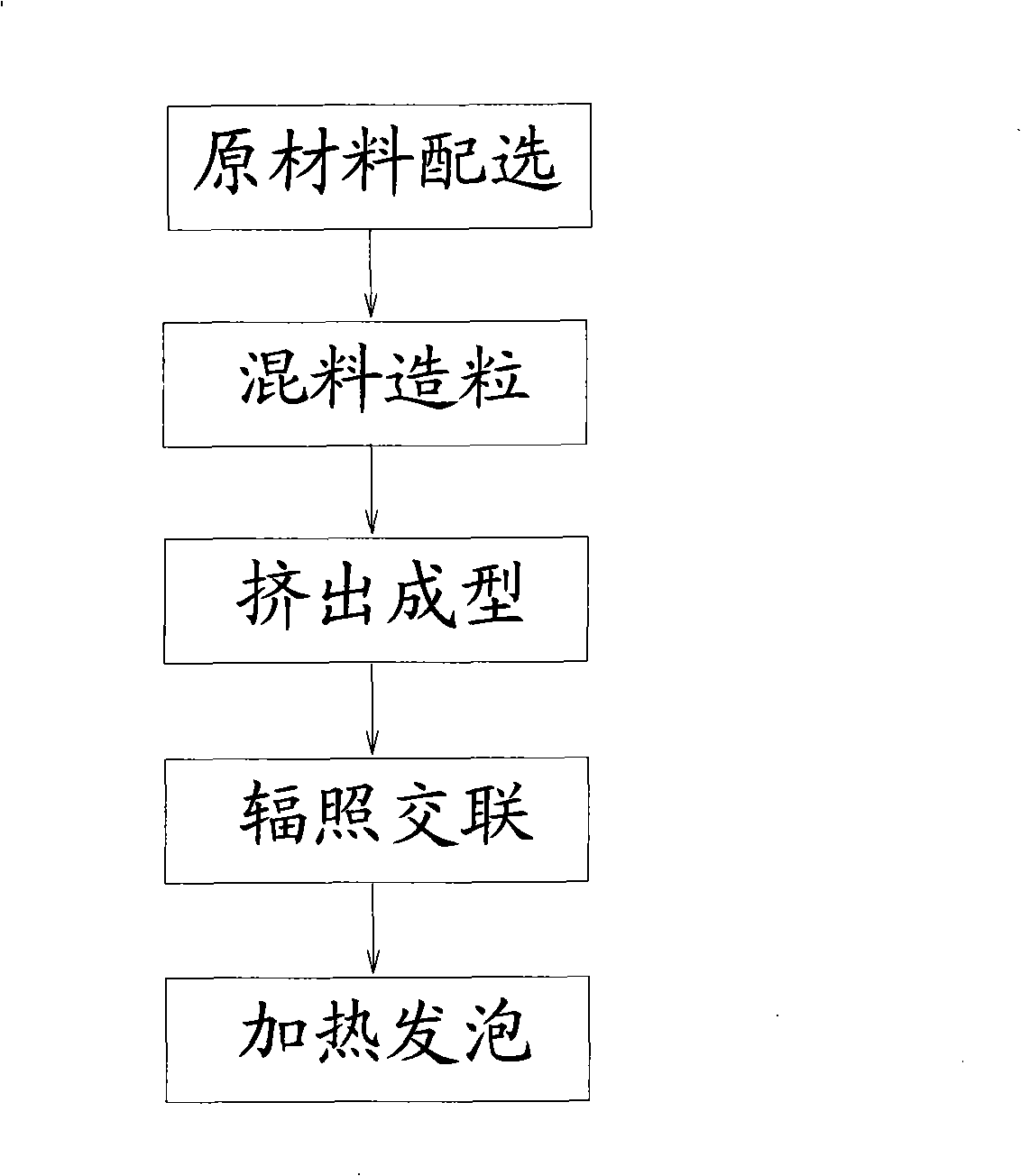

[0020] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

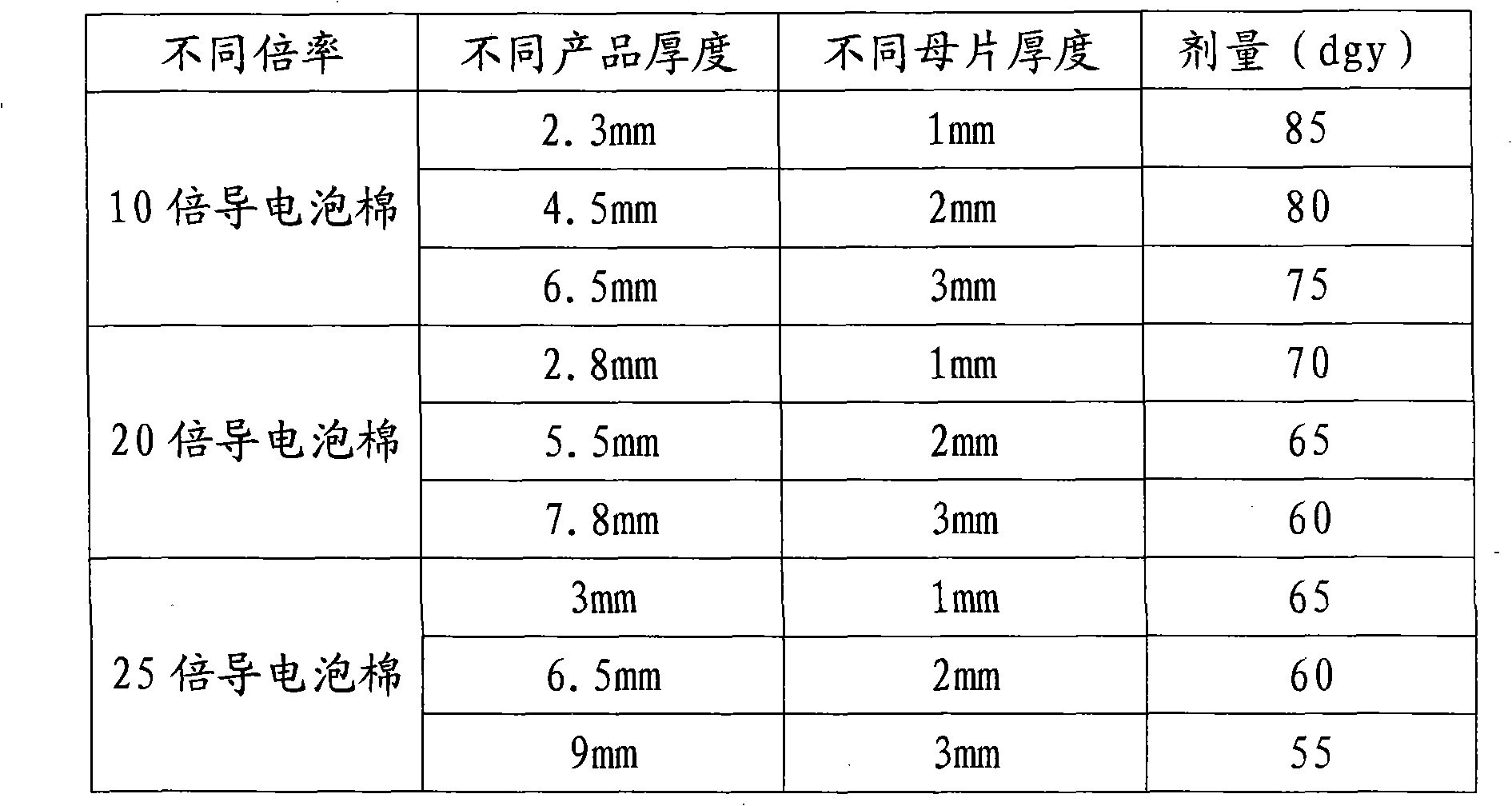

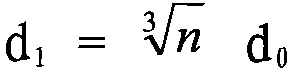

[0021] Radiation cross-linking is that ionizing radiation makes linear polyethylene cross-link polymers with a certain network structure, and polyethylene is a crystalline linear polymer material. When the crystal structure is melted, the melt viscosity will drop sharply, which is not conducive to gas retention and difficult Made into foam material. Radiation cross-linking can be cross-linked through special radiation processing to improve the temperature-viscosity change of polyethylene. After this radiation modification process, it is beneficial to retain gas during the foaming process and form a more delicate cell structure. Among the raw materials of polyethylene foaming system, various additives can also improve the quality of foaming according to a certain proportion. By adding special conductive carbon black, special IXPE radiation cross-linked polyeth...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com