Method for preparing corrosion inhibition anion intercalated layered double hydroxides/oxide composite material and application

A technology of anion intercalation and composite materials, which is applied in the field of preparation and application of corrosion-inhibiting anion intercalation hydrotalcite/oxide composite materials, and can solve problems such as human body insecurity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] Implementation 1: Material Synthesis Method

example 1

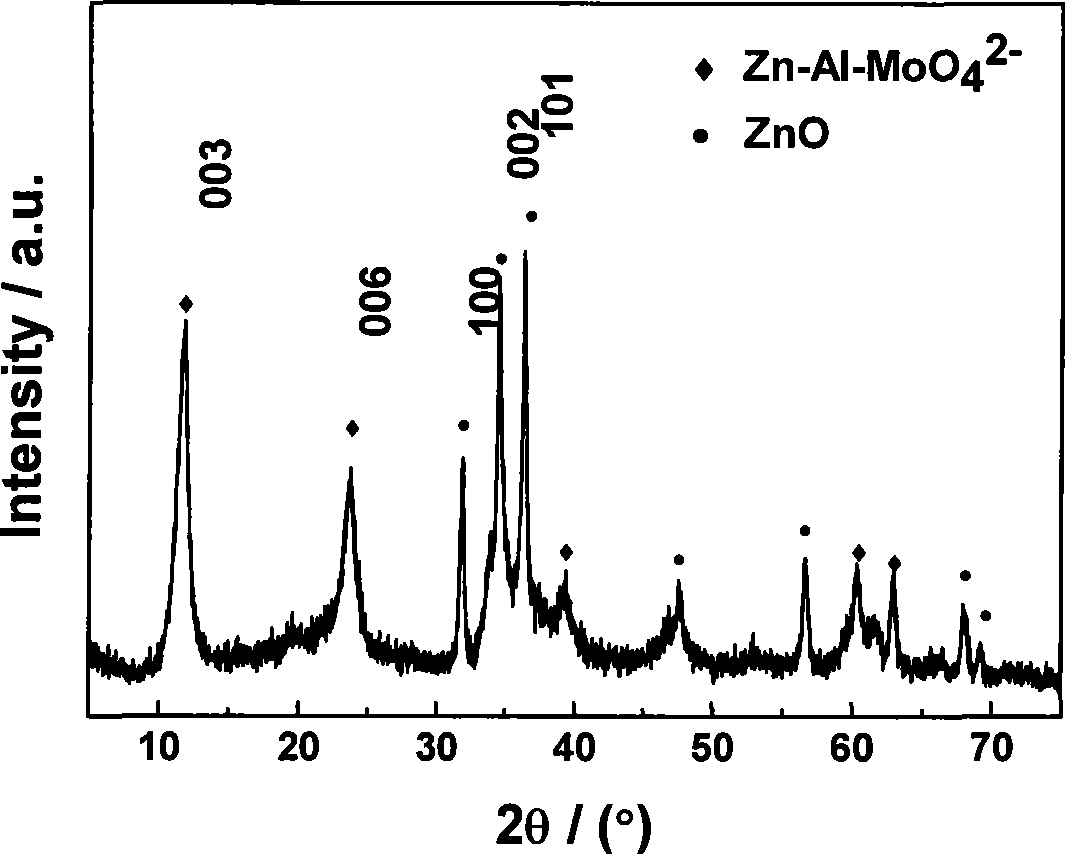

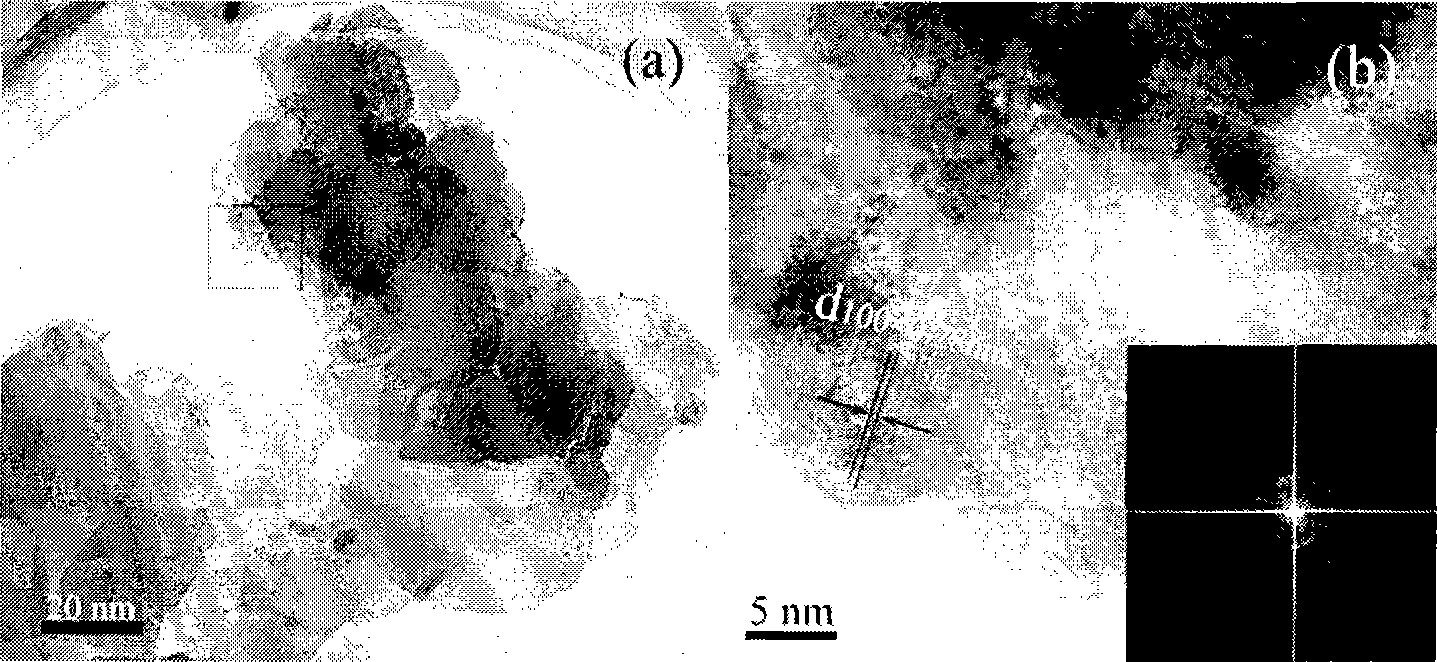

[0020] Example 1: Preparation of one-step co-precipitation method of molybdate corrosion inhibitor intercalated Zn-Al hydrotalcite / nano-ZnO composite

[0021] Step: take a certain amount of Zn (NO 3 ) 2 ·6H 2 O and Al(NO 3 ) 3 9H 2 O, ensure Zn / Al = 2.2 ~ 2.5 (molar ratio), dissolve in 200mL to remove CO 2 Distilled water, as a salt solution; make OH - / [Zn 2+ +Al 3+ ]=2.2 (mol ratio) NaOH is made into 2M solution, as alkaline solution; Take a certain amount of Na 2 MoO 4 .2H 2 O, make MoO 4 2- / Al 3+ The molar ratio is 2, dissolved in 100mL to remove CO 2 After distilling water, move it into a three-necked bottle, adjust the pH=9 to 10, and set aside; in a water bath at 75-80°C, add the salt solution and alkali solution drop by drop to the Na 2 MoO 4 In the three-necked bottle of the solution, control the pH value of NaOH to always keep it between 10.0 and 11.0. Nitrogen protection, reflux for 12 hours and then sink for 12 hours. Filter with suction, wash th...

example 2

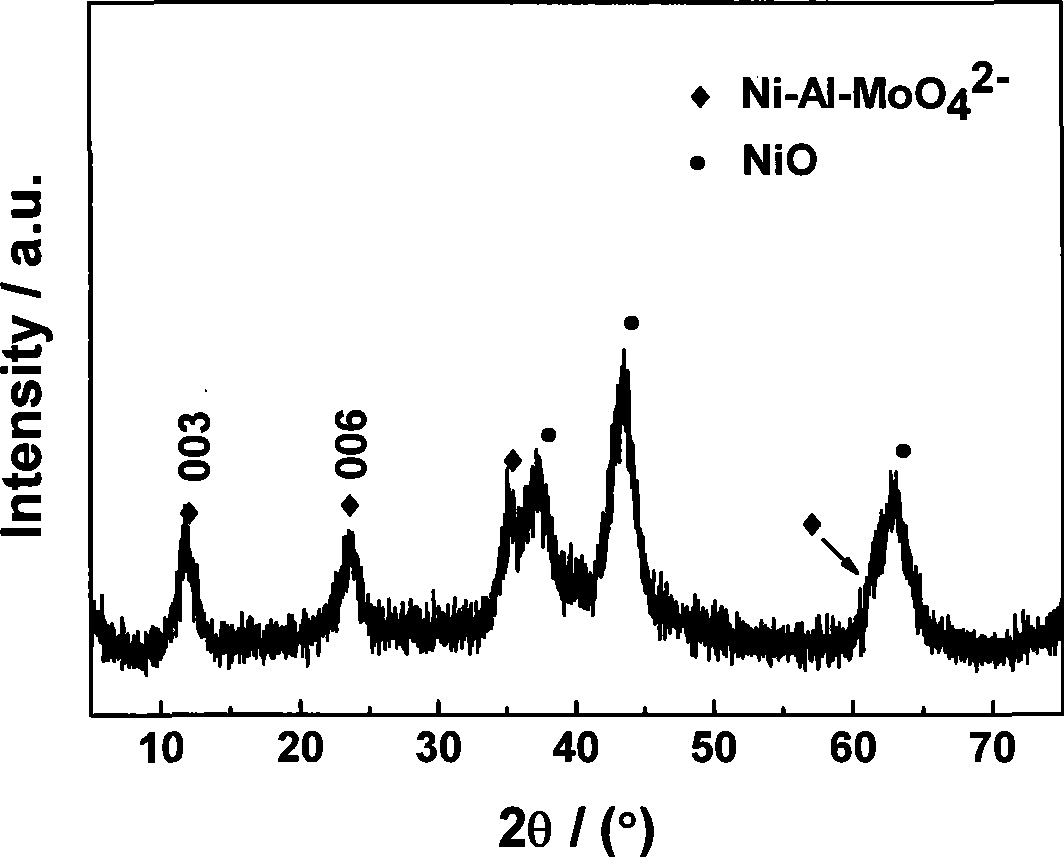

[0022] Example 2: Molybdate corrosion inhibitor intercalated nickel-aluminum hydrotalcite / nano-nickel oxide composite

[0023]Step: Prepare Ni-Al-CO as Example 1 3 2- The hydrotalcite / nano-nickel oxide precursor was calcined at 620°C for 3h. After roasting, the samples were soaked in CO removal 2 In distilled water, add sodium molybdate salt solution and alkali solution (diluted ammonia water) drop by drop at the same speed at the same time, in N 2 Reaction for 4h under protection, satisfying MoO 4 2- / Al 3+ The molar ratio is 0.8-1.2, and the pH is 9.5. Filtration, CO removal 2 The filter cake was washed with distilled water until neutral, dried in an oven at 80°C, and ground.

[0024] The above examples further describe the technical solutions of the present invention, but the specific methods, formulations and instructions used are not limitations of the present invention.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com