Polyether polyamide elastomer

A technology of polyamide elastomer and polyether type, which is applied in the field of polyether type polyamide elastomer, which can solve the problems of poor transparency and achieve the effects of excellent impact resistance and low temperature flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0145] Now, the present invention will be described below with reference to Examples and Comparative Examples. However, the present invention is not limited to these Examples.

[0146] Physical properties were measured in the following manner.

[0147] 1) Relative viscosity (ηr) (0.5 wt / vol% m-cresol solution, 25°C):

[0148] The Ostwald viscometer measures the concentration in the special grade reagent m-cresol as a solvent to be 5g / dm 3 Relative viscosity at time.

[0149] 2) Terminal carboxyl group concentration ([COOH]):

[0150] To about 1 g of the polymer was added 40 mL of benzyl alcohol, and the resulting mixture was heated under nitrogen to dissolve the polymer. To the obtained sample solution was added phenolphthalein as an indicator, and the solution was titrated using an N / 20 potassium hydroxide-ethanol solution.

[0151] 3) Terminal amino concentration ([NH 2 ]):

[0152] About 1 g of the polymer was dissolved in 40 mL of a mixed solution of phenol and meth...

preparation Embodiment 1

[0176] Preparation Example 1: Preparation of PAE1

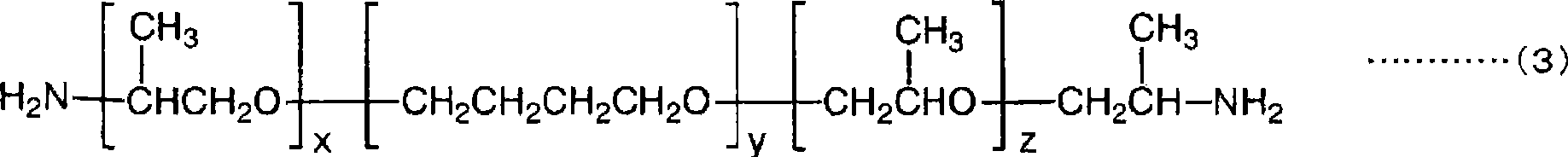

[0177] In a 70 L pressure vessel equipped with a stirrer, thermometer, torque gauge, pressure gauge, nitrogen inlet, pressure controller and polymer outlet, 14.000 kg of 12-aminododecanoic acid produced by UBE Industries Ltd., 0.986 kg Adipic acid of 4.628 kg of XYX type triblock polyether diamine (XTJ-542, produced by Huntsman Corp., total amine: 1.94 meq / g), 0.384 kg of isophorone diamine (product Name: VESTAMINIPD, manufactured by Degussa Japan Co., Ltd.), 6 g of sodium hypophosphite monohydrate, and 60 g of a heat-resistant agent (Tominox 917, manufactured by Yoshitomi Pharmaceutical Co., Ltd.). The gas inside the container was completely replaced with nitrogen. Then, while nitrogen gas was supplied at a rate of 186 liters / hour and the pressure inside the container was adjusted to 0.05 MPa, the container was heated from room temperature to 230° C. over 3.5 hours. While maintaining the pressure inside the vessel at 0.05 ...

preparation Embodiment 2

[0179] Preparation Example 2: Preparation of PAE2

[0180] In a 70 L pressure vessel equipped with a stirrer, thermometer, torque gauge, pressure gauge, nitrogen inlet, pressure controller and polymer outlet, 12.292 kg of 12-aminododecanoic acid produced by UBE Industries Co., Ltd., 1.246 kg Adipic acid, 6.000kg of XYX type triblock polyether diamine (XTJ-542, produced by Huntsman company, total amine: 1.94meq / g), 0.462kg of isophorone diamine (product name : VESTAMIN IPD, produced by Degussa Japan Co., Ltd.), 6 g of sodium hypophosphite monohydrate, and 60 g of a heat-resistant agent (Tominox 917, produced by Yoshitomi Pharmaceutical Co., Ltd.). The gas inside the container was completely replaced with nitrogen. Then, while nitrogen gas was supplied at a rate of 186 liters / hour and the pressure inside the container was adjusted to 0.05 MPa, the container was heated from room temperature to 230° C. over 3.5 hours. While maintaining the pressure inside the vessel at 0.05 MPa,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| bending strength | aaaaa | aaaaa |

| flexural modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com