Filter unit for wastewater treatment and production of drinking water

A wastewater treatment and filter technology, applied in water/sewage treatment, biological water/sewage treatment, water/sludge/sewage treatment, etc., can solve the problem of not being connected to the public wastewater network, unable to replace the filter board /membrane etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

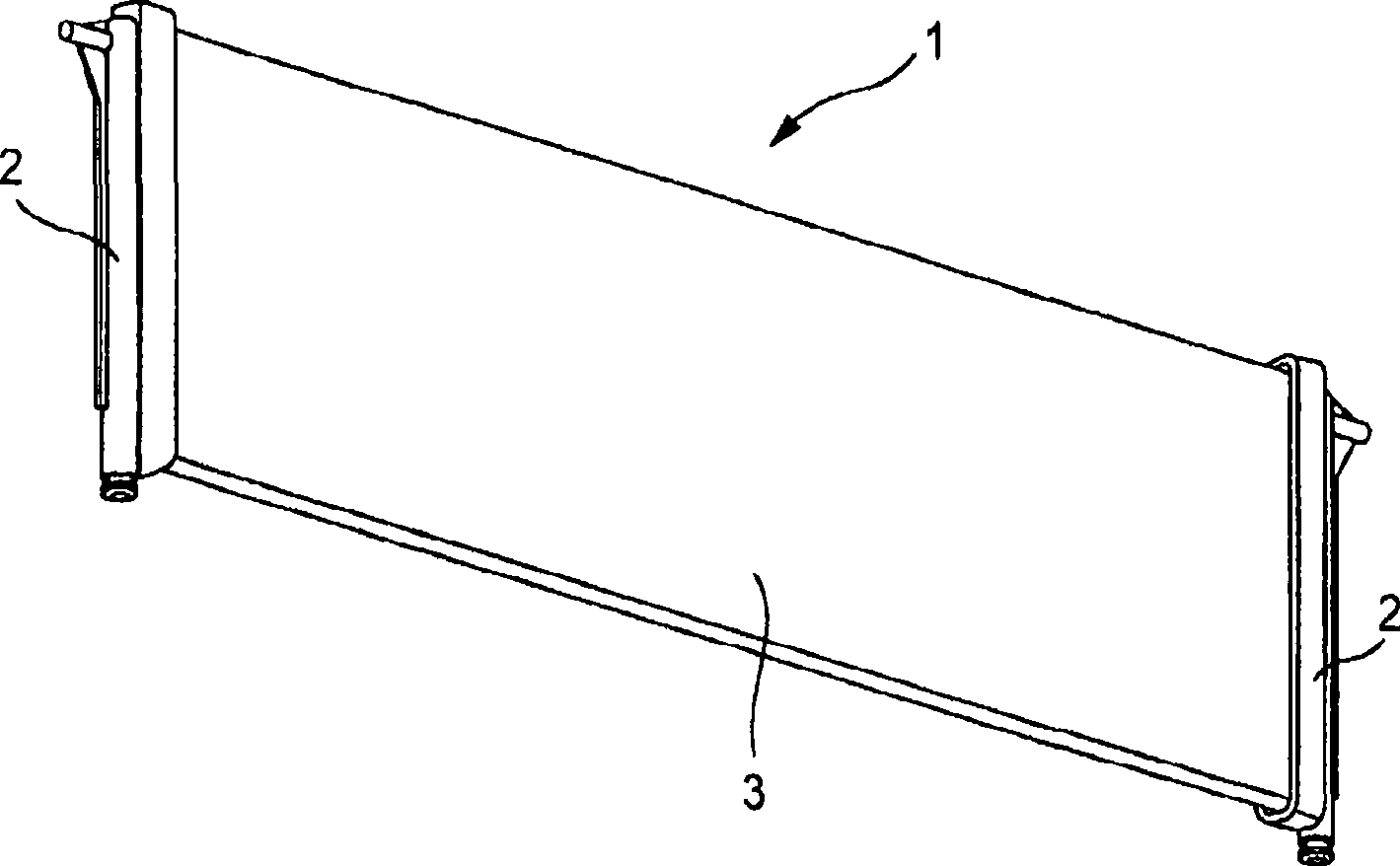

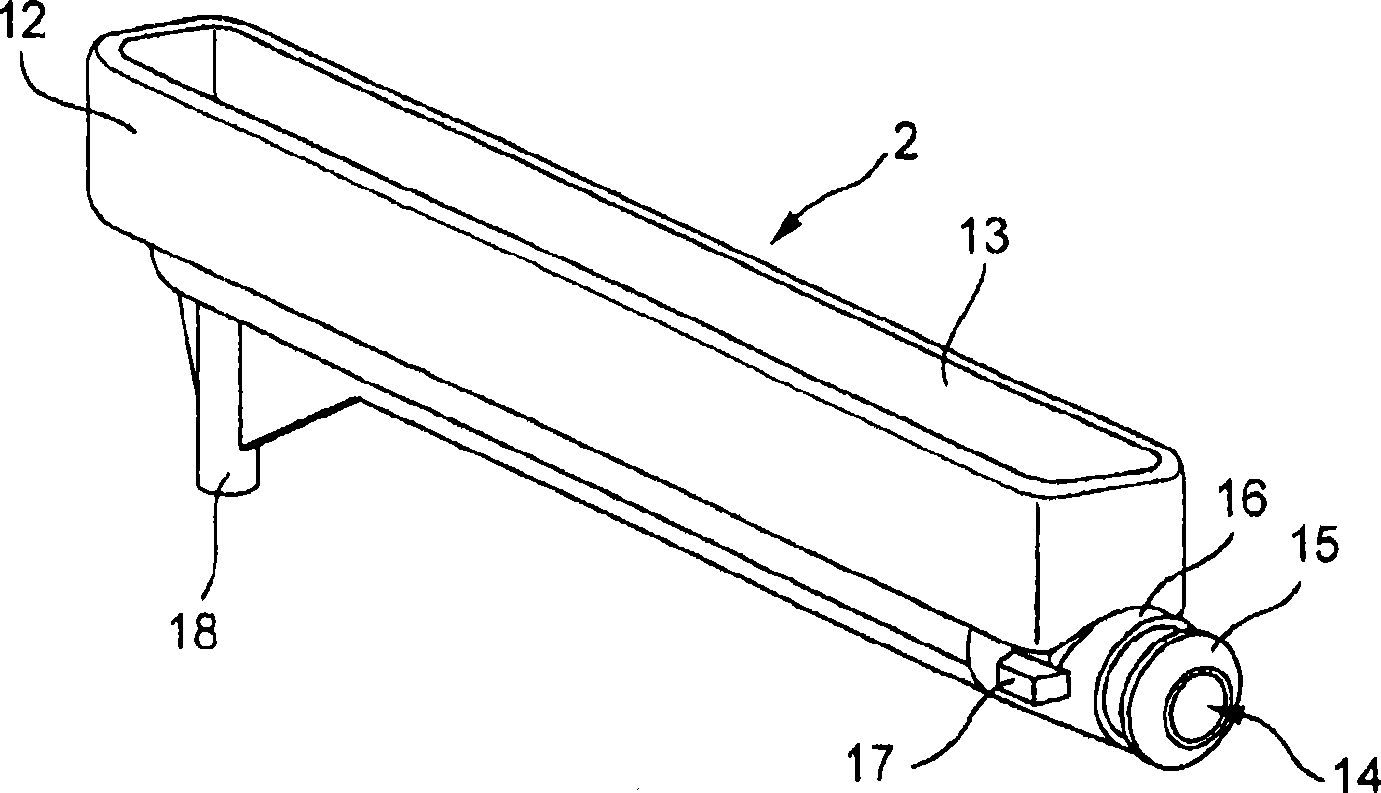

[0087] figure 1 shows a filter unit according to the invention comprising two mounts 2 in which flat filters 3 made of ceramic are fastened on two opposite end faces in a liquid-tight manner superior. In all cases, this fastening is carried out in the edge region belonging to the side of the filter 3, and this fastening is realized in particular by means of adhesive bonding, figure 1 Any details of the adhesive bonding are not shown. For this purpose, corresponding edge regions of the filter 3 are pushed into the two mounts 2 , so that an adhesive bond is provided between the inner surfaces of the mounts 2 and the corresponding outer surface of the filter 3 . The following will also combine figure 2 This is described in more detail.

[0088] according to figure 1 The filter 3 is a rectangular flat filter made of ceramics comprising alumina ceramics having a pore size of about 1 μm. The substrate material is produced in one piece by extrusion, in particular by means of s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com