Silicon dioxide wall material microcapsule as well as preparation method and application thereof

A silica and microcapsule technology, applied in microcapsule preparation, microsphere preparation, etc., can solve the problems of unsatisfactory self-healing effect of concrete cracks, small particle size of silica wall material microcapsules, application limitations, etc. Excellent UV resistance, stable structure and performance, and the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

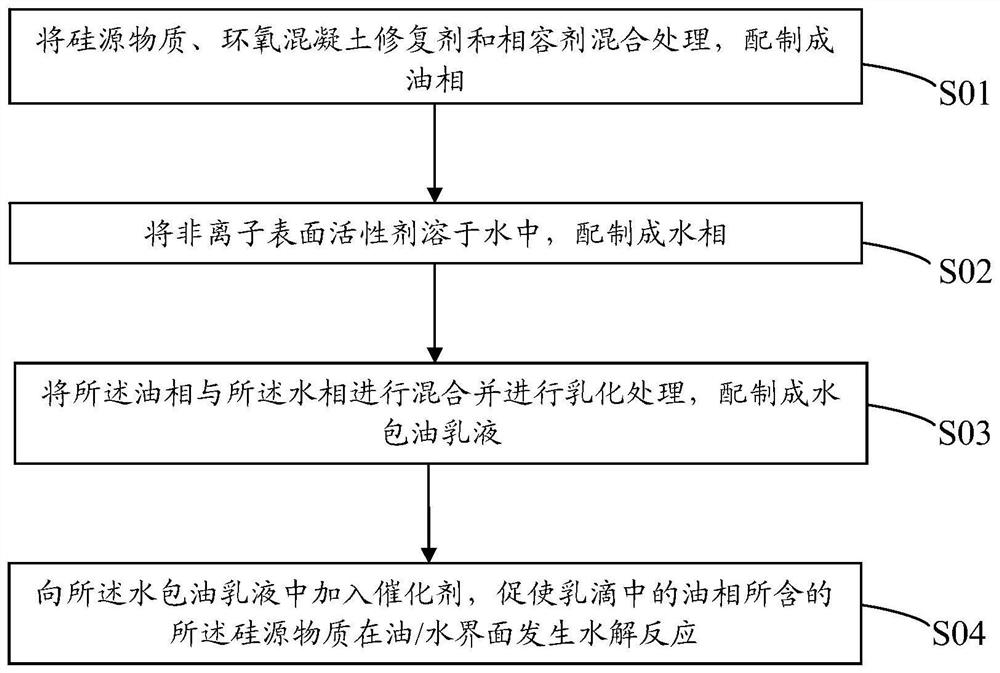

[0032] On the other hand, the embodiment of the present invention also provides a preparation method of the above-mentioned silica wall material microcapsules. The preparation method technological process of described silica wall material microcapsule is as follows figure 1 As shown, it includes the following steps:

[0033] Step S01: mixing silicon source material, epoxy concrete repair agent and compatibilizer to form an oil phase;

[0034] Step S02: dissolving the non-ionic surfactant in water to form an aqueous phase;

[0035] Step S03: mixing and emulsifying the oil phase and the water phase to prepare an oil-in-water emulsion;

[0036] Step S04: Adding a catalyst to the oil-in-water emulsion to promote the hydrolysis reaction of the silicon source material contained in the oil phase in the emulsion droplets at the oil / water interface to generate silica wall material microcapsules.

[0037] Wherein, in the step S01, the epoxy concrete repair agent has oily characterist...

Embodiment 1

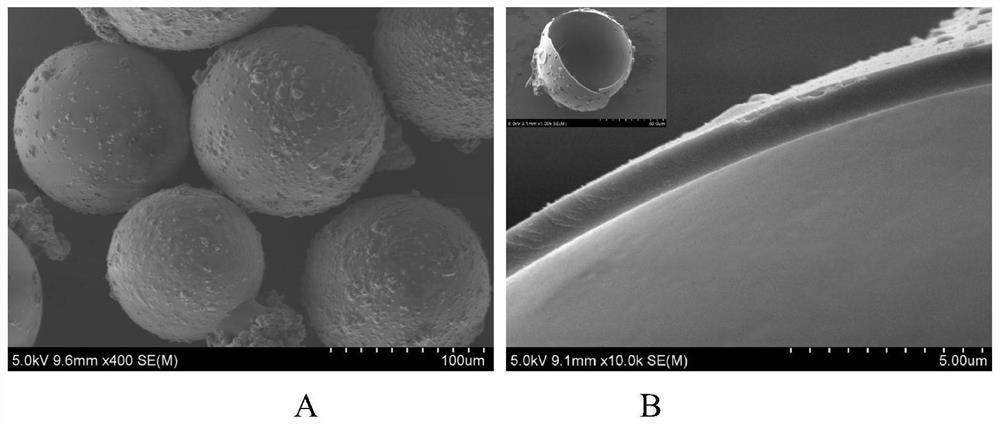

[0053] This embodiment provides a silica wall material microcapsule and a cultivation method for its preparation method. The silica wall material microcapsules include a silica microcapsule shell and a capsule core, and the silica microcapsule shell is coated on the capsule core. Wherein, the average particle size of the silica microcapsules is 110.7 μm, the average wall thickness of the shell is 1.8 μm, and the capsule core contains alicyclic epoxy UVR-6128.

[0054] The preparation method of the silica wall material microcapsules comprises the following steps:

[0055] S11: Take 5g of epoxy resin E-51 (viscosity 11,000mPa·s), 4g of cycloaliphatic epoxy UVR-6128, and 10g of ethyl orthosilicate, and stir and mix at room temperature until a uniform oil phase is obtained;

[0056] S12: Mix 2g of polyether poloxame 407 and 150mL of deionized water with magnetic stirring at 35°C to form a solution, that is, a homogeneous aqueous phase;

[0057] S13: Slowly drop the oil phase int...

Embodiment 2

[0061] This embodiment provides a silica wall material microcapsule and a cultivation method for its preparation method. The silica wall material microcapsules include a silica microcapsule shell and a capsule core, and the silica microcapsule shell is coated on the capsule core. Wherein, the average particle size of the silica microcapsules is 110.7 μm, the average wall thickness of the shell is 1.8 μm, and the capsule core contains alicyclic epoxy ERL-4221.

[0062] The preparation method of the silica wall material microcapsules comprises the following steps:

[0063] S11: Take 5g of epoxy resin E-44 (viscosity 20,000mPa·s), 3g of cycloaliphatic epoxy ERL-4221, and 10g of phenyltrimethoxysilane at room temperature with magnetic stirring and mixing until a uniform oil phase is obtained;

[0064] S12: Mix 2g of PS50-b-PEO114 nonionic amphiphilic block polymer (MW:PS:5000, PEO:5000Dalton) and 150mL of deionized water with magnetic stirring at 35°C to make a solution, that is,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com