Continuous brazing composite aluminum-based brazing wire applying nanometer aluminum trioxide and preparation method of continuous brazing composite aluminum-based brazing wire applying nanometer aluminum trioxide

A technology of aluminum oxide and composite aluminum, applied in welding equipment, welding/welding/cutting articles, welding media, etc., can solve the problems of reduced toughness and plasticity, increased brittleness, unfavorable extrusion molding, etc., to improve toughness and Effect of plasticity, elimination of brittleness, and improvement of extrusion forming performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

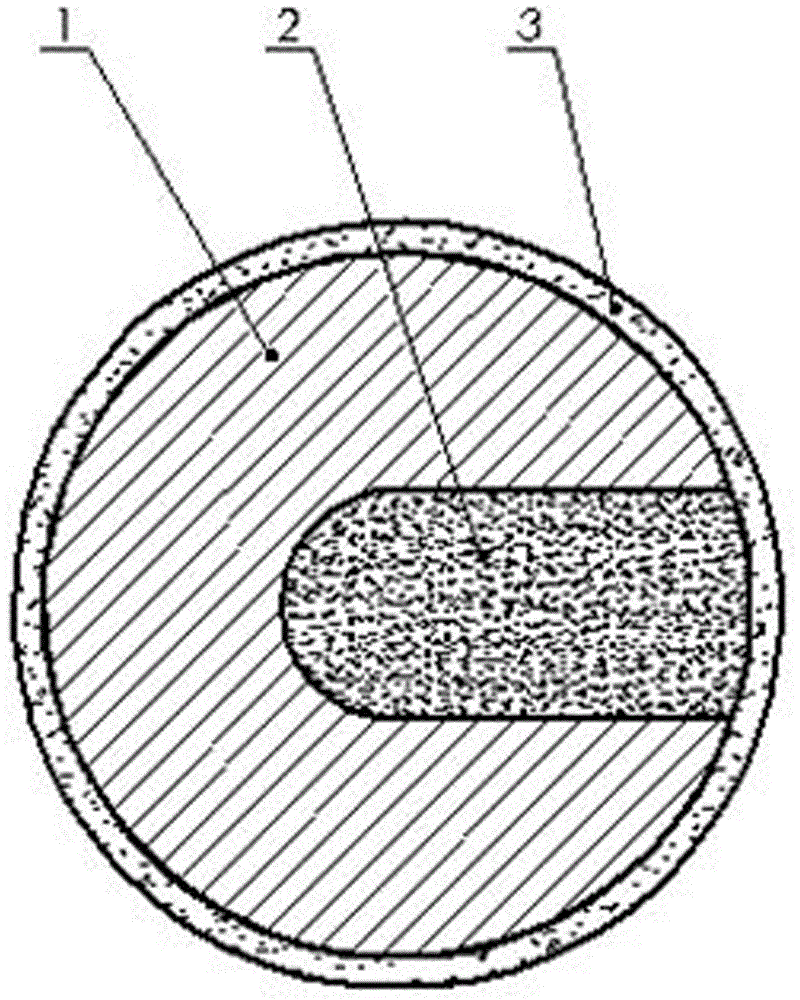

[0040] The continuous brazing composite aluminum-based brazing wire using nano-alumina is composed of an aluminum-based brazing core material with grooves on the outer surface and a non-corrosion composite of aluminum wrapped in the groove on the surface of the core material. Flux and the moisture-proof coating sprayed on the surface of the flux. The aluminum-based brazing wire core material is an aluminum alloy profile with a "C"-shaped cross-section and a circular outer circumference. The outer diameter of the circle is ф2.0mm, and the weight ratio of the chemical composition of the solder is: Al: 74; Si : 5; Zn: 13; Cu: 6; Ni: 2; trace elements: Sr: 0.02; Mg: 0.01; rare earth Ce: 0.02, nano-Al 2 o 3 : 0.01. The weight ratio of each component of the composite flux is: Nocolok (K 3 AlF 6 +KAIF 4 Eutectic): 50; KBr: 10; CsF: 5, the state is a 300 mesh powder mixture. The carrier of the composite flux is polyethylene glycol with a relative molecular weight of 6000, and it...

Embodiment 2

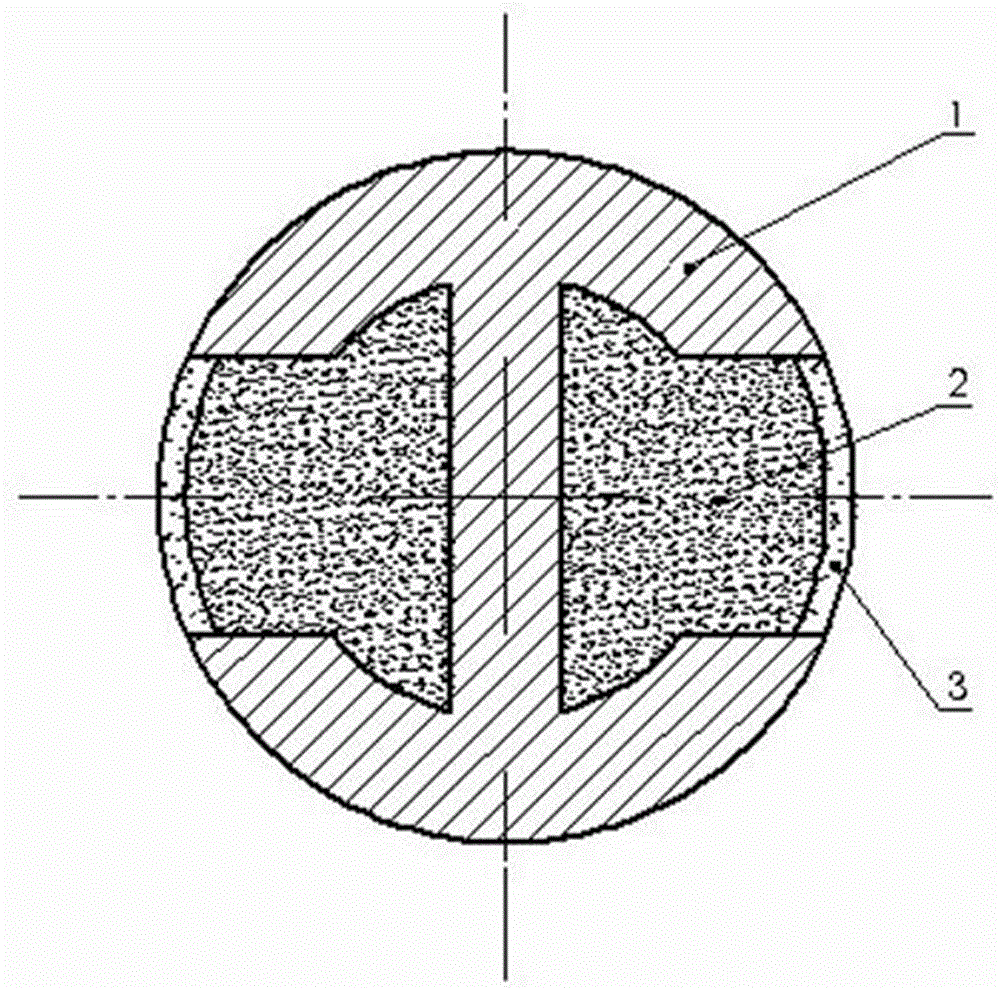

[0044] Continuous brazing composite aluminum-based brazing wire core material has a "Y"-shaped cross-sectional shape and a circular profile on the outer circumference. The diameter of the circle is Φ8.0mm, and the weight ratio of the chemical components of the brazing alloy is: AL;81.5; Si: 12; Zn: 4; Cu: 2; Ni: 0.5, Sr: 0.1; Mg: 0.1; Ce: 0.01; Nano Al 2 o 3 : 0.15. The weight ratio of each component of the composite flux is: Nocolok (K 3 AlF 6 +KAIF 4 Eutectic): 60; KBr: 12; CsF: 6, the state is a powder mixture of 800 mesh. The carrier of the composite flux is polyethylene glycol with a relative molecular weight of 10,000, and its weight ratio is 22.

[0045] The weight ratio of each component of the composite brazing wire coating layer is: Nocolok (K 3 AlF 6 +KAIF 4 Eutectic): 40; KBr: 8, synthetic resin: 52, and the coating thickness on the wire surface is 80 μm.

[0046] All the other are with embodiment 1.

Embodiment 3

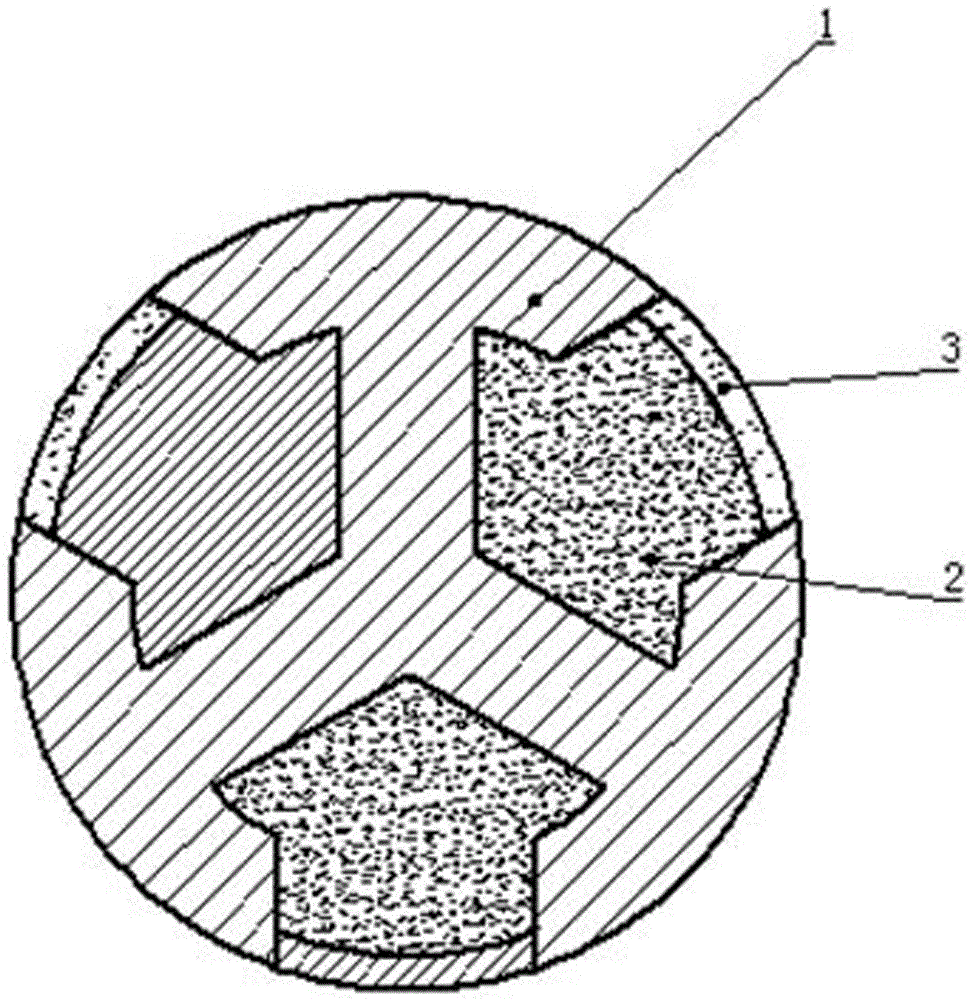

[0048] The continuous brazing composite aluminum-based brazing wire using nano-aluminum oxide has a cross-sectional shape of a "c"-shaped structure and a circular outer circumference. The outer diameter of the circle is ф2.5mm. The weight ratio of chemical composition is: Al: 73; Si: 10; Zn: 10; Cu: 4; Ni: 3; trace elements are: Sr: 0.01; Mg: 0.05; rare earth Ce: 0.1, nanometer Al 2 o 3 : 0.2. The weight ratio of each component of the composite flux is: Nocolok (K 3 AlF 6 +KAIF 4 Eutectic): 55; KBr: 11; CsF: 4, the state is a 300-mesh powder mixture. The carrier of the composite flux is polyethylene glycol with a relative molecular weight of 8000, and its weight ratio is 30.

[0049] The weight ratio of each component of the composite aluminum-based brazing wire coating layer is: Nocolok (K 3 AlF 6 +KAIF 4 Eutectic): 50; KBr: 10, synthetic resin: 40, the coating thickness on the wire surface is 40μm.

[0050] All the other are with embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com