Multi-pipe wind conveying feeder for fishponds

A technology of wind conveying and multi-pipeline, applied in fish farming, application, animal husbandry, etc., can solve the problem of not meeting market needs, and achieve the effect of high work efficiency, large throwing area and large throwing volume.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

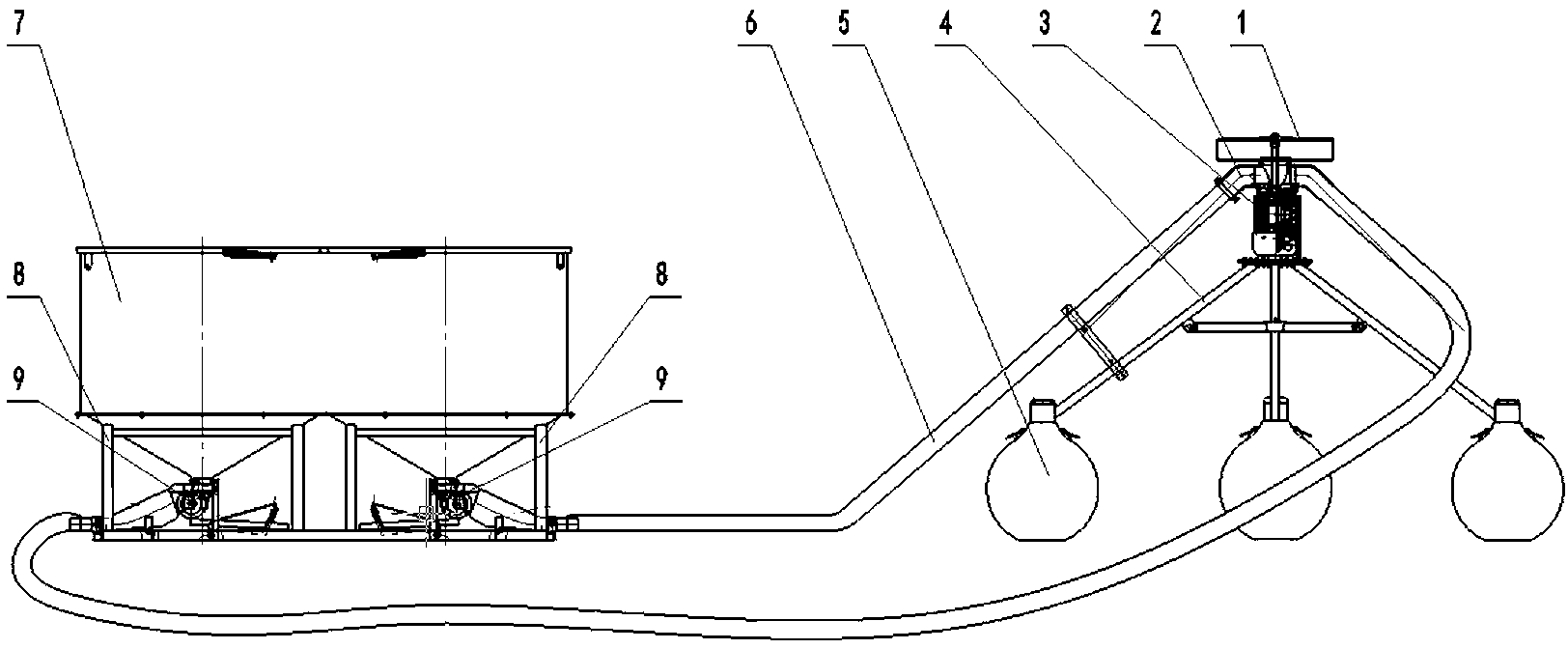

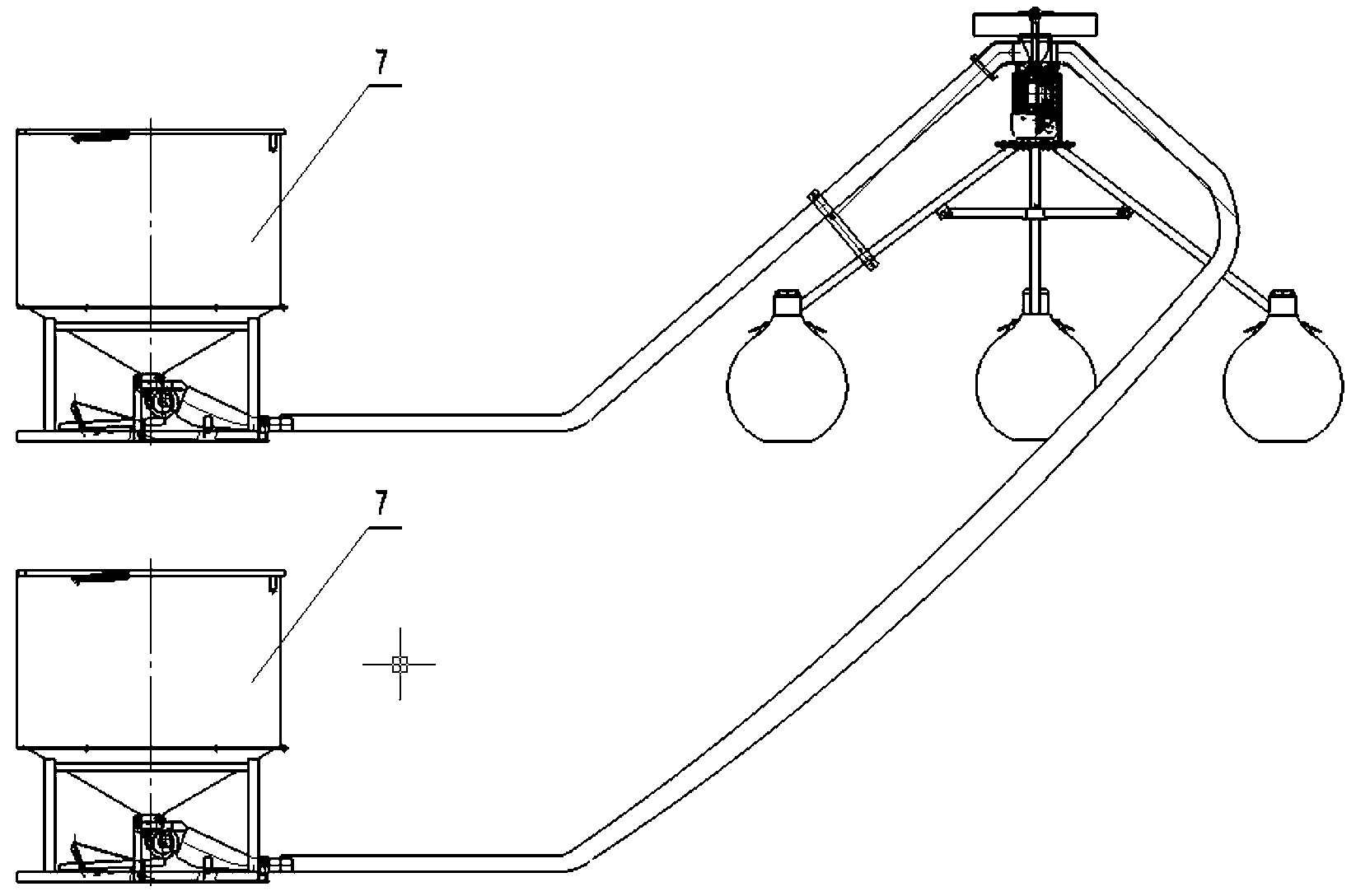

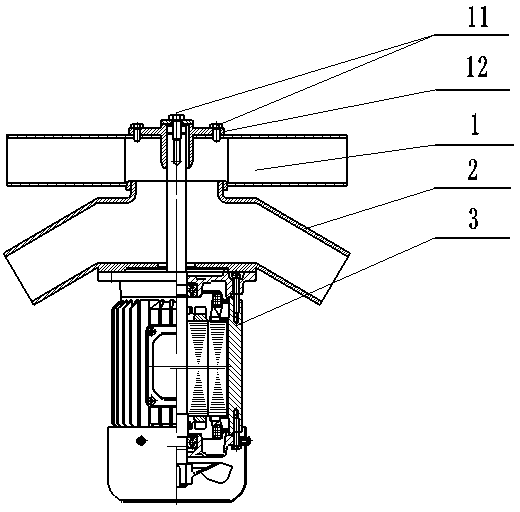

[0013] Such as figure 1 , 3 As shown in , 4, the feeding machine has a silo and several vibrating buckets, including a suction and throwing wind wheel 1, a multi-head wind drum 2, a long-axis motor 3, a support rod assembly 4, a floating body 5, a delivery pipe 6, Feed bin 7, base 8, receiving hopper 9, vibrating bucket 13 and vibrating motor 14, feeding bin 7, receiving hopper 9, vibrating bucket 13 and vibrating motor 14 are installed on the base 8, and some discharge holes are established at the bottom of feeding bin 7, The vibrating bucket 13 is installed below each discharge hole, the discharge port of the vibrating bucket 13 is aligned with the hopper 9, the vibrating bucket 13 is connected to the vibrating motor 14, the floating body 5 is installed at the bottom of the support rod assembly 4, and the long-axis motor 3 is installed on On the support rod assembly 4, the multi-head wind drum 2 is installed on the base of the long-axis motor 3 and locked with bolts. The t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com