Compound microorganism oil extraction method for low permeability oilfield

A technology of composite microorganisms and composite microorganisms, which is applied in the fields of mining fluids, earthwork drilling, wellbore/well components, etc., can solve the problems of large recoverable oil reserves, increase crude oil production, increase recovery, and increase spillover area effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

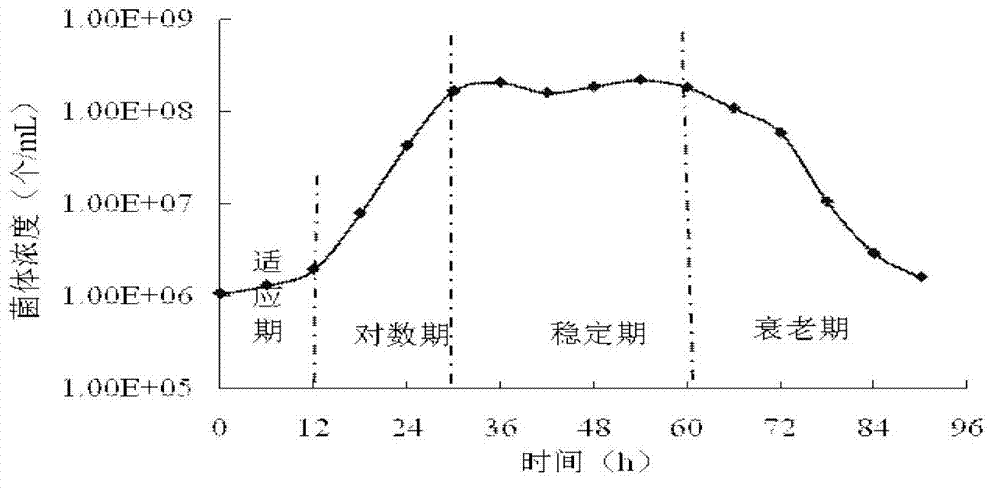

[0030] A method for composite microbial oil recovery in low-permeability oilfields, characterized in that the method comprises the following steps: 1) Surfactant-producing strains and polymer-producing strains are respectively cultured in shake flasks indoors, and amplified by primary and secondary seed tanks And production tank fermentation production, obtain the fermented liquid of the highly active surfactant-producing strain and the fermented liquid of producing the polymer strain;

[0031] 2) Mix the fermentation liquid of the surfactant-producing strain and the polymer-producing strain produced by fermentation in step 1) in a volume ratio of 1:1 to obtain a mixed liquid, that is, a composite microbial bacterial liquid;

[0032] 3) The composite microbial bacterial liquid obtained in step 2) is directly injected into the oil layer through the water injection well as an oil displacement agent, and crude oil is obtained from the production well.

Embodiment 2

[0034] 1. The method comprises the following steps:

[0035] 1) Surfactant-producing strains and polymer-producing strains are respectively cultivated in indoor shake flasks, first-level and second-level seed tanks are enlarged, and production tanks are fermented to obtain high-activity fermented surfactant-producing strains and Fermentation broth of polymer-producing strains;

[0036] 2) Mix the fermentation liquid of the surfactant-producing strain and the polymer-producing strain produced by fermentation in step 1) in a volume ratio of 1:1 to obtain a mixed liquid, that is, a composite microbial bacterial liquid;

[0037] 3) The composite microbial bacterial liquid obtained in step 2) is directly injected into the oil layer through the water injection well as an oil displacement agent, and crude oil is obtained from the production well.

[0038] The surfactant-producing strain is Pseudomonas aeruginosa YM4 (Pseudomonas aeruginosa), and its metabolite is a rhamnose surfacta...

Embodiment 3

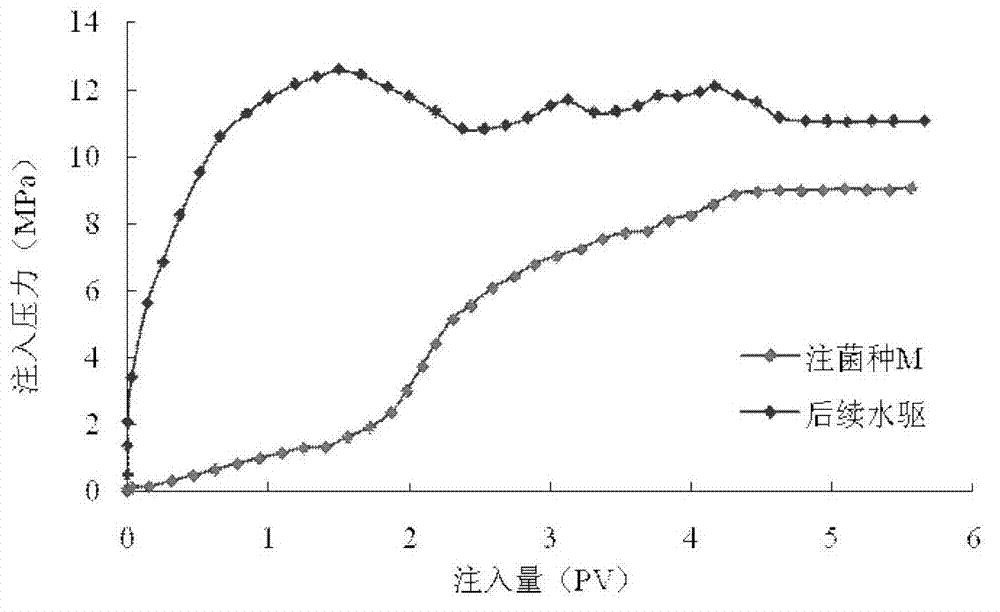

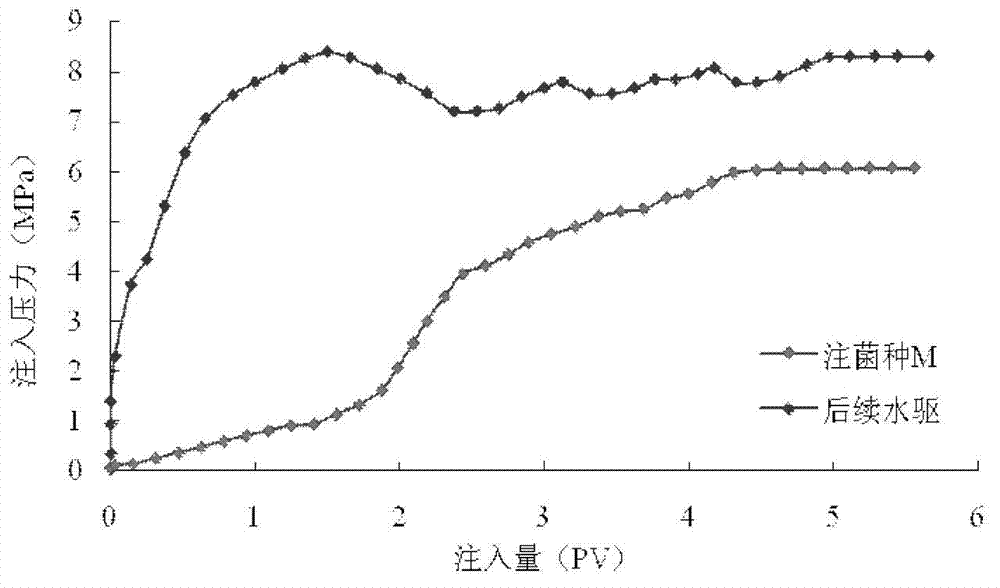

[0063] The present invention is applied on-site in the Yuanmao test area of Wayaobao Oil Production Plant of Yanchang Petroleum. The microbial oil displacement test of 10 injections and 32 extractions has been carried out. The method of injecting water injection wells has been adopted. Since the field test, the injection pressure has decreased, and the average injection pressure From 5.1MPa to 4.6Mpa, the depressurization range reaches 10%. The production of oil wells increased steadily. A total of 17 oil wells in the test area saw obvious oil increase effects, and the average daily oil production of a single well in the test well group increased by more than 20%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Salinity | aaaaa | aaaaa |

| Surface tension | aaaaa | aaaaa |

| Interfacial tension | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com