High-temperature resistant assistant steam expelling foaming agent

A technology for assisting steam and foaming agents, which is applied in the direction of drilling compositions, chemical instruments and methods, etc., and can solve the problems that foaming agents cannot meet high temperature resistance, fluorine-containing surfactants are extremely expensive, and are difficult to popularize and use. , to achieve the effects of improving the development effect, good plugging and profile control ability, and increasing the displacement volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

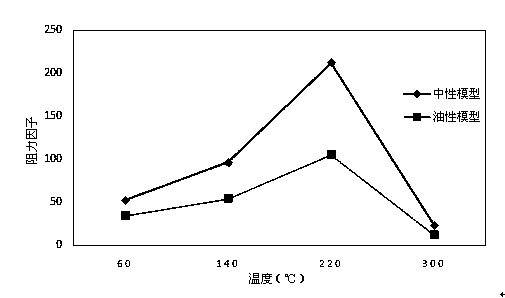

[0019] Embodiment 1 A kind of high temperature resistant auxiliary steam flooding foaming agent

[0020] The ingredients and their parts by weight are: 8 parts of foaming agent, 22 parts of foam stabilizer and 70 parts of water;

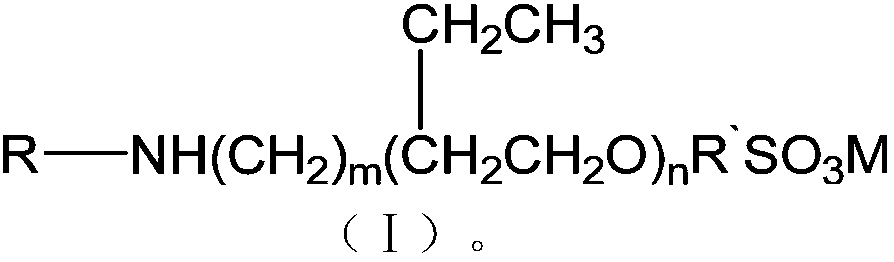

[0021] Blowing agent is the product of the reaction of N-dodecyl polyethylene and butylene ether polymer sodium tetradecylsulfonate, and the structural formula obtained is shown in (I):

[0022]

[0023] In the described blowing agent structural formula (I), R is dodecyl, m is 3, n is 22, R' is tetradecyl, and M is sodium ion;

[0024] The foam stabilizer is polyacrylamide.

Embodiment 2

[0025] Embodiment 2 A kind of high temperature resistant auxiliary steam flooding foaming agent

[0026] The ingredients and parts by weight are: 5 parts of foaming agent, 30 parts of foam stabilizer and 60 parts of water;

[0027] Blowing agent is the product of the reaction of N-heptyl polyethylene and butylene ether polymer sodium octadecylsulfonate, and the structural formula obtained is similar to the blowing agent structural formula in Example 1; wherein R is a heptyl group, m is 2, n is 35, R' is octadecyl, and M is a potassium ion;

[0028] Described foam stabilizer is polyvinyl alcohol.

Embodiment 3

[0029] Embodiment 3 A kind of high temperature resistant auxiliary steam flooding foaming agent

[0030] The ingredients and their parts by weight are: 10 parts of foaming agent, 10 parts of foam stabilizer and 85 parts of water;

[0031] Blowing agent is the product of the reaction of N-octadecyl polyethylene and butylene ether polymer sodium decanyl sulfonate, and the structural formula obtained is similar to the blowing agent structural formula in Example 1; wherein R is octadecyl , m is 4, n is 10, R' is a decanyl group, and M is an ammonium ion;

[0032] The foam stabilizer is an alkanolamide.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com