Full-bore multistage-key switch type fracturing slide sleeve

A technology of key switch and fracturing sliding sleeve, which is applied in the direction of mining fluid, wellbore/well components, earthwork drilling and production, etc. It can solve the problems of error accumulation, sliding sleeve easy to fail, and identification mechanism failure, etc., and achieve good recognition effect , avoid superposition, easy to open and close

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0061] Below in conjunction with accompanying drawing, the present invention will be further described:

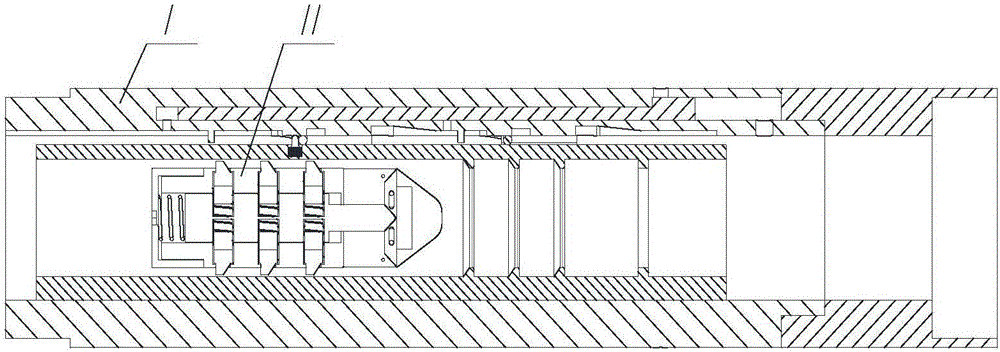

[0062] Depend on figure 1 Shown: sliding sleeve actuator I and sliding sleeve switch mechanism II.

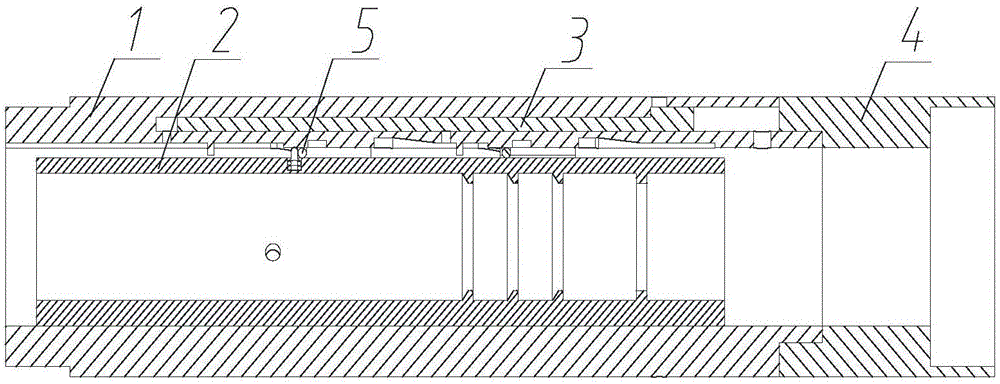

[0063] Depend on figure 2 Shown: the sliding sleeve actuator, including the sliding sleeve main body 1, the inner cylinder 2, the pressure regulating piston 3, the base 4, and the pulling rod 5.

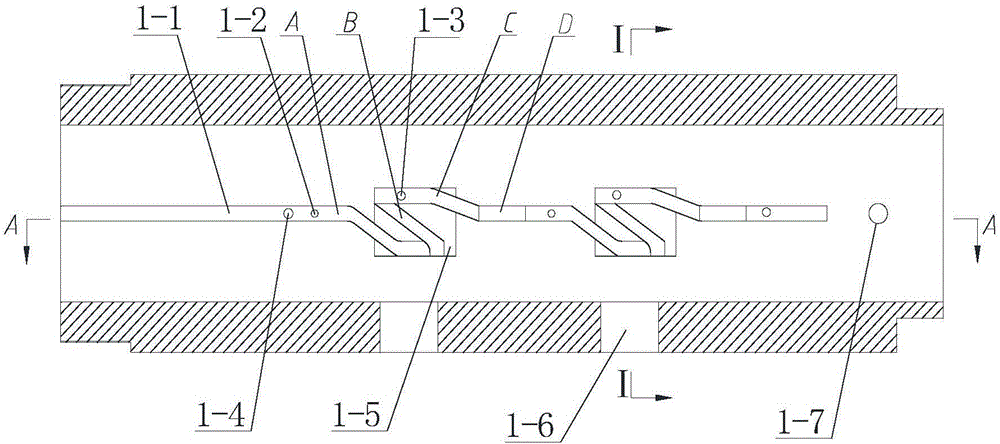

[0064] Depend on Figure 3A combine Figure 3B , 3C As shown: the main body 1 of the sliding sleeve is cylindrical, and both ends of the main body 1 of the sliding sleeve have external threads, the upper end of which is threaded with other components or other tools, and the lower end is threaded with the base.

[0065] A grooved guide rail 1-1 is provided along the inner wall of the main body of the sliding sleeve, and the entire grooved guide rail 1-1 is provided with a primary fracturing section, a secondary fracturing section...n fracturing sections, and each fracturing s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com