Fuel cell hydrogen recovery device

A fuel cell and recovery device technology, applied in fuel cells, fuel cell additives, electrical components, etc., can solve problems such as wasting fuel hydrogen, leakage, and reducing the service life of solenoid valves, and achieve uniform and safe exhaust and ensure safety performance , the effect of ensuring safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

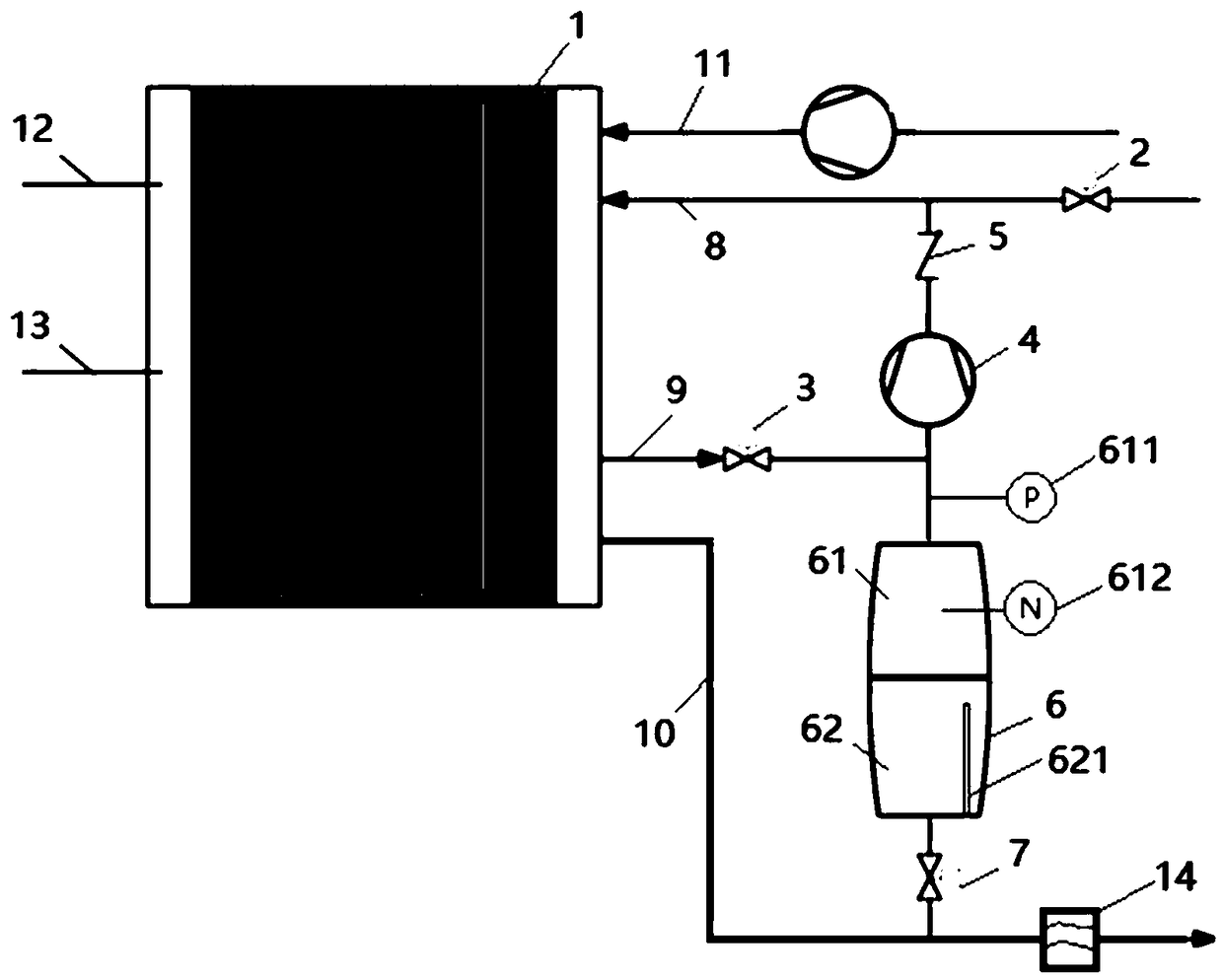

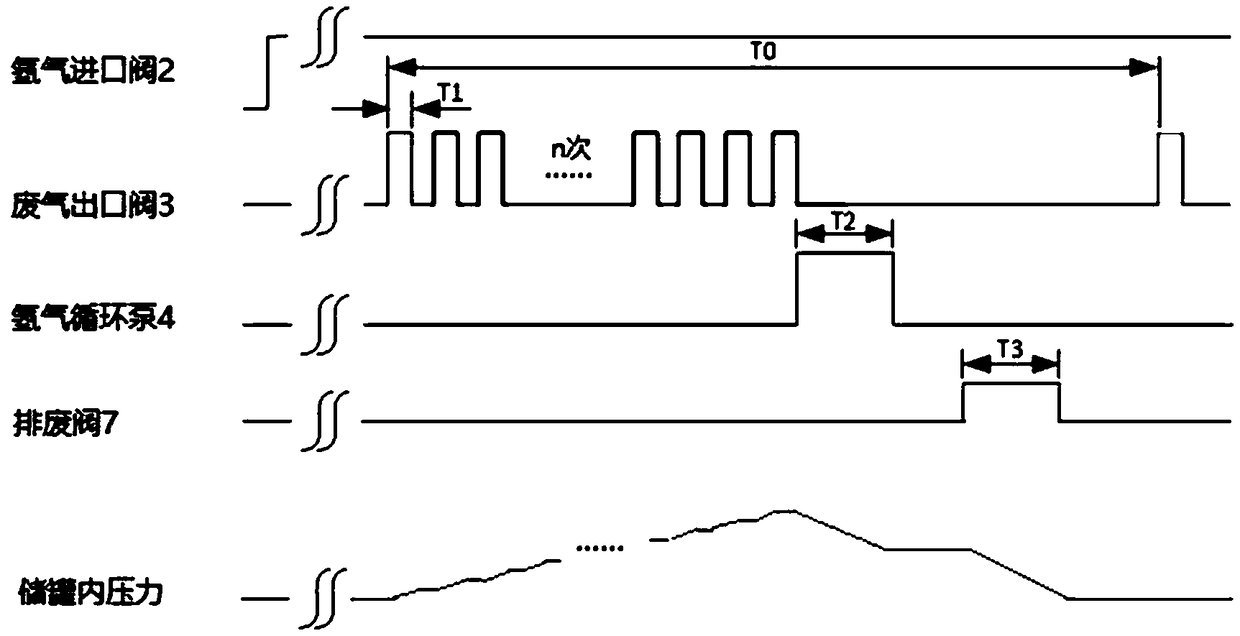

[0034] Such as figure 1 As shown, the present invention provides a fuel cell hydrogen recovery device, including a fuel cell 1, a controller, a hydrogen recovery pipe provided with a hydrogen circulation pump 4 and a shut-off valve 5, an air inlet pipe 11 connected to the fuel cell 1 and an air inlet pipe 11 respectively. Exhaust pipe 10, hydrogen inlet pipe 8 with hydrogen inlet valve 2 and hydrogen exhaust pipe 9 with hydrogen outlet valve 3, hydrogen recovery pipe is connected with hydrogen inlet pipe 8, and the device also includes an integrated gas-liquid separation The storage tank 6, the gas-liquid separation storage tank 6 is integrally formed by the upper storage tank 61 and the lower gas-liquid separator 62 or separately connected through the mesh, and the storage tank 61 is respectively connected with the hydrogen exhaust pipe 9 and the hydrogen recovery pipe , the gas-liquid separator 62 discharges waste water and excess nitrogen through a waste discharge pipe prov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com