Automatic zipper head

An automatic head and zipper technology, applied in the field of zippers, can solve the problems of complicated assembly and inconvenient operation, and achieve the effects of convenient operation, simple assembly, and ensuring elastic stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

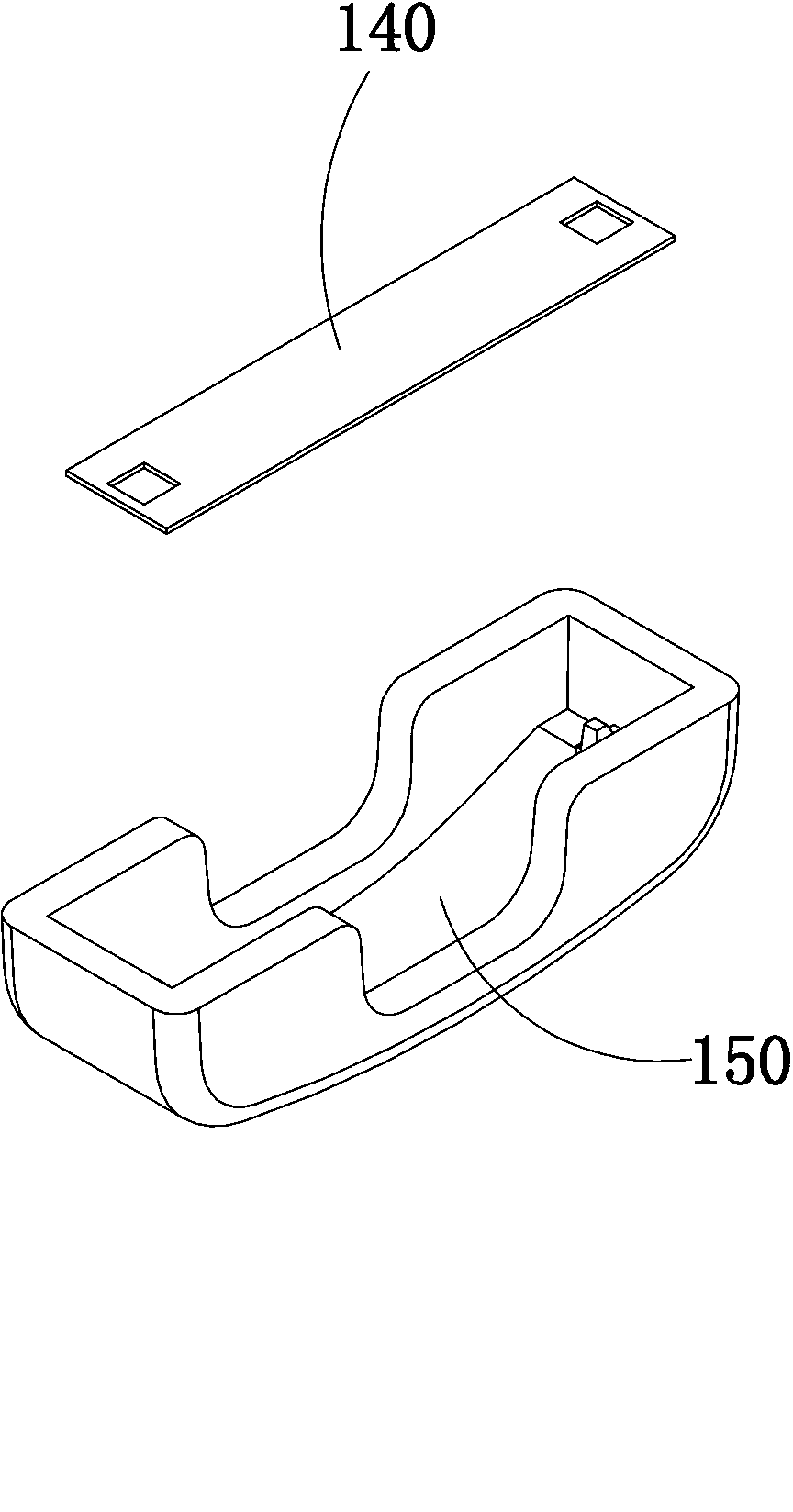

[0033] see Figure 1 to Figure 3 , the zipper automatic head includes a slider body 110 , a pull piece 120 , a hook 130 , a straight elastic piece 140 and a cap 150 . The slider body 110 , the pull piece 120 , the hook 130 , the straight elastic piece 140 and the cap 150 are sequentially arranged from bottom to top, and assembled to form the automatic head of the zipper. Both ends of the horse hook 130 are inserted into the slider body 110 , and the horse hook 130 and the slider body 110 form a receiving space for accommodating the end of the pull piece 120 . see image 3 , Figure 6 The two ends of the cap 150 are mechanically connected to the slider body 110, the two ends of the straight elastic piece 140 are mechanically connected to the inner wall of the cap 150, the straight elastic piece 140 and the cap 150 form an elastic space, the The middle part of the straight elastic piece 140 is adjacent to the horse hook 130 .

[0034] read on Figure 1 to Figure 3 , the sli...

Embodiment 2

[0041] The automatic head of the zipper in the present embodiment 2 is roughly the same as the automatic head of the zipper in the embodiment 1, the main difference is:

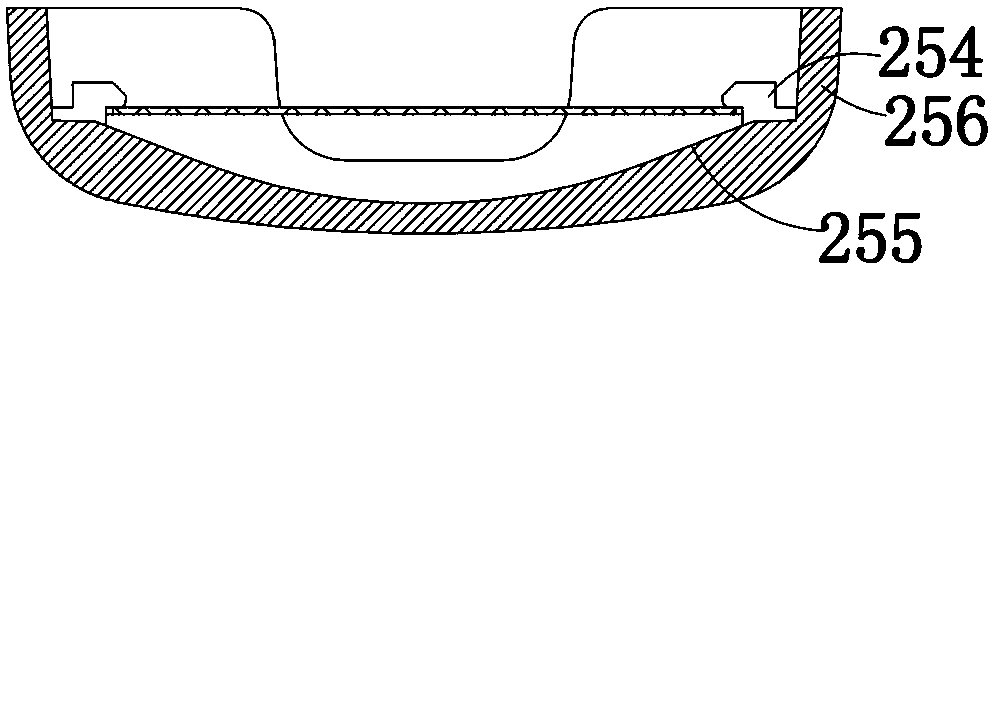

[0042] see Figure 7 , the first pier portion and the second pier portion all include fixing protrusions 254, and each fixing protrusion 254 is respectively arranged on the side inner walls 256 of the first pier portion and the second pier portion, and the fixing protrusions are respectively It is perpendicular to the side inner walls 256 of the first pier and the second pier.

Embodiment 3

[0044] The automatic head of the zipper in the present embodiment 3 is roughly the same as the automatic head of the zipper in the embodiment 1, the main difference is:

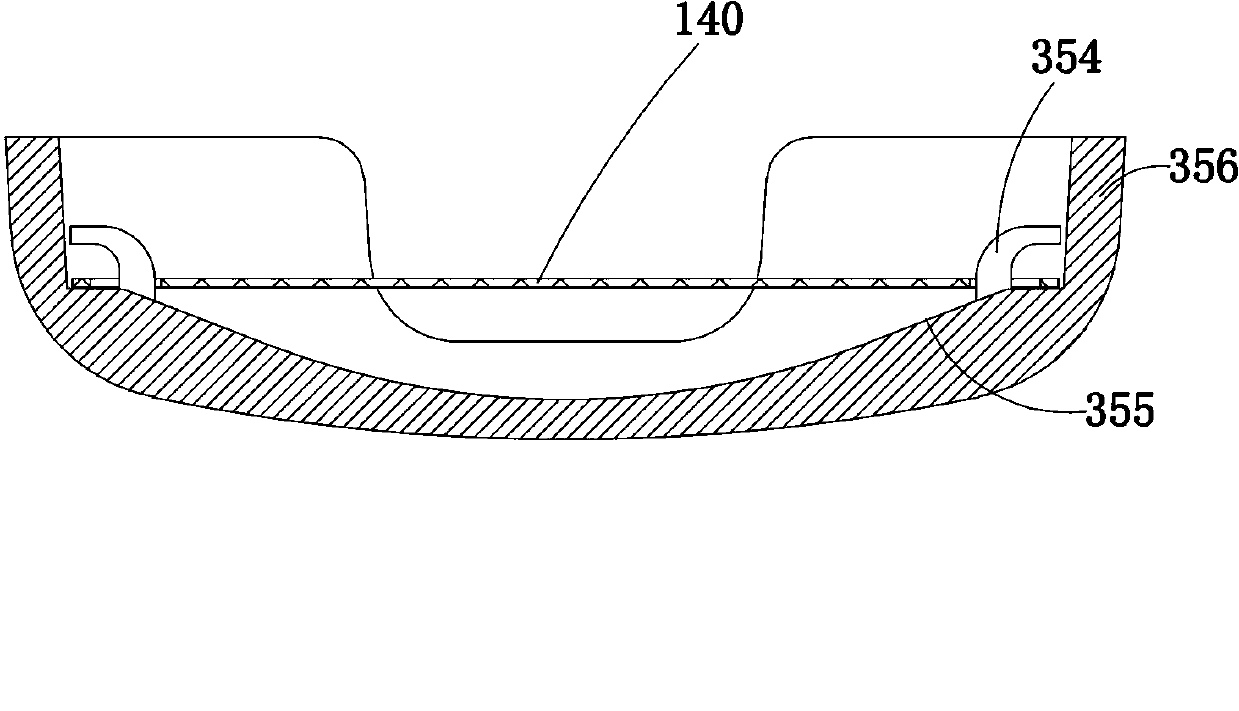

[0045] see Figure 8 , Figure 9 , the first pier portion and the second pier portion both include fixing protrusions 354, and the two fixing protrusions 354 are arc-shaped protrusions, and the two ends of each fixing protrusion 354 are respectively arranged on each pier portion The top inner wall 355 and the side inner wall 356 are vertically arranged with the top inner wall 355 and the side inner wall 356 respectively.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com