Labor-saving hand riveter

A technology for riveting guns and gun barrels, which is applied in the field of hand tools, can solve problems such as complex structure of riveting guns, inconvenient operation, and low efficiency of use, and achieve the effects of simple structure, convenient operation, and high work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

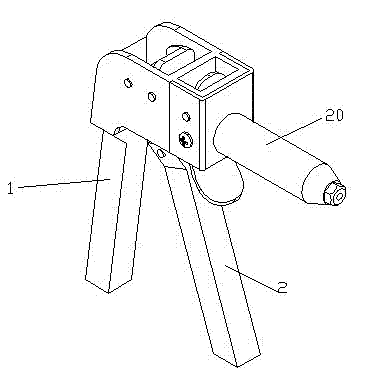

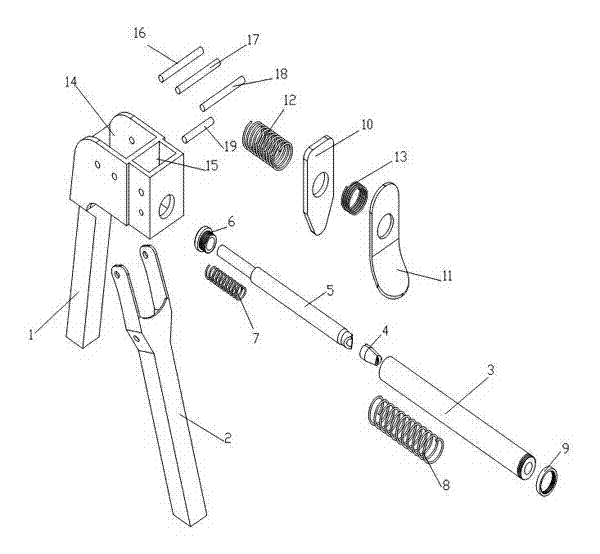

[0028] Such as figure 1 , a labor-saving riveting gun, comprising a gun body 1, a handle 2 and a riveting device, the handle is movably arranged on the gun body, and the riveting device is movably connected to the handle; the riveting device includes A gun barrel 3 and a tiger's mouth assembly 4 for clamping the rivet, the gun barrel 3 is driven and connected with the handle, and the gun barrel 3 can be stopped and released by a stopper 11 when the handle is driven to move. In the embodiment, the stopper is a pull button; the tiger jaw assembly is movably arranged in the gun barrel through an intermediate push assembly.

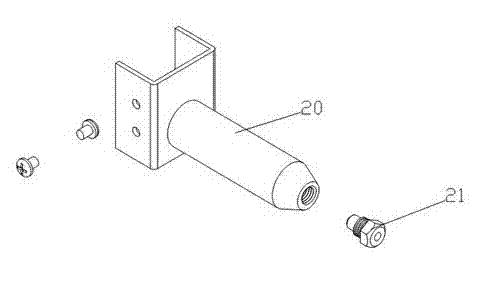

[0029] Such as Figure 4 , the gun barrel 3 is elastically connected to the gun body through the trigger 11, and the handle is pulled with one hand, and the handle drives the gun barrel to move on the gun body, and the trigger is pulled by hand. Buckle 11, and the described gun barrel is fixed by the described trigger; release the handle, and then pull the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com