Manufacturing method of acetic acid-containing cloth die cutting piece

A production method and technology of acetic acid cloth, applied in chemical instruments and methods, lamination auxiliary operations, cellulose plastic material layered products, etc., can solve problems such as low efficiency, waste of labor, poor products, etc., to improve production capacity, reduce Labor, the effect of improving the pass rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

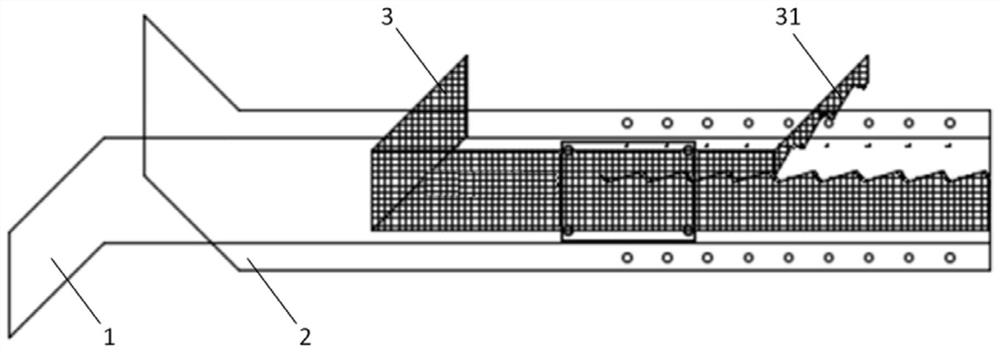

[0037] A production method of a die-cut piece containing acetate cloth, such as Figure 8 , the acetate cloth 3 comprises horizontal and vertical well-shaped weaving patterns, and the method comprises the following steps:

[0038] (1) The bonding of the first-level material tape: the release film 2 and the acetate cloth 3 are sequentially bonded on the protective film 1 to form a first-level material tape;

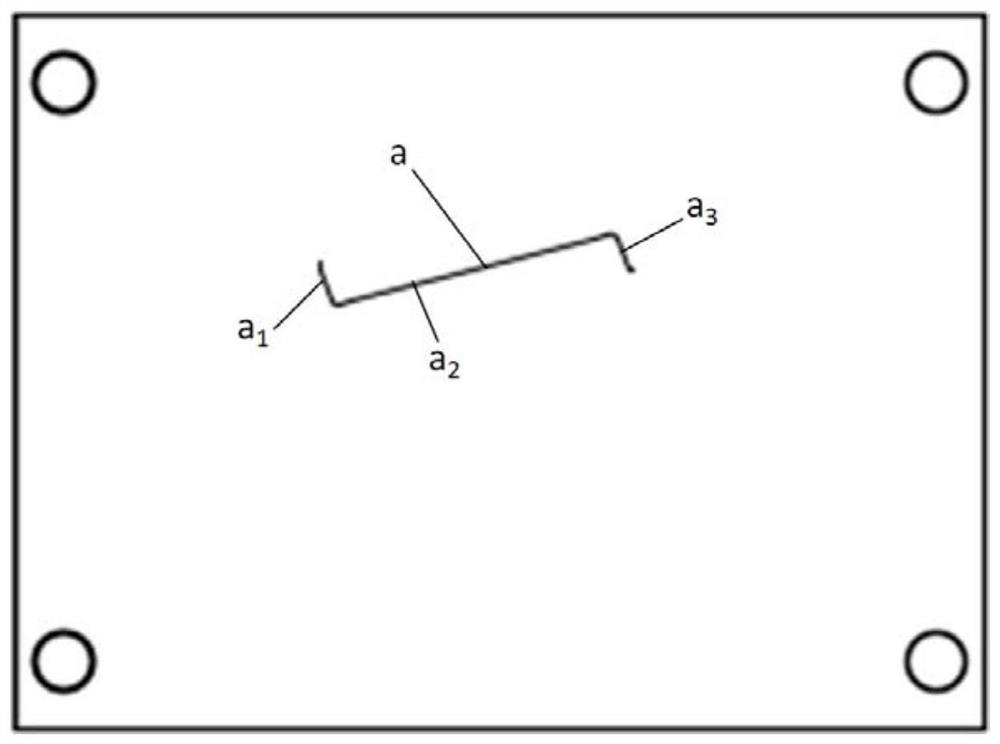

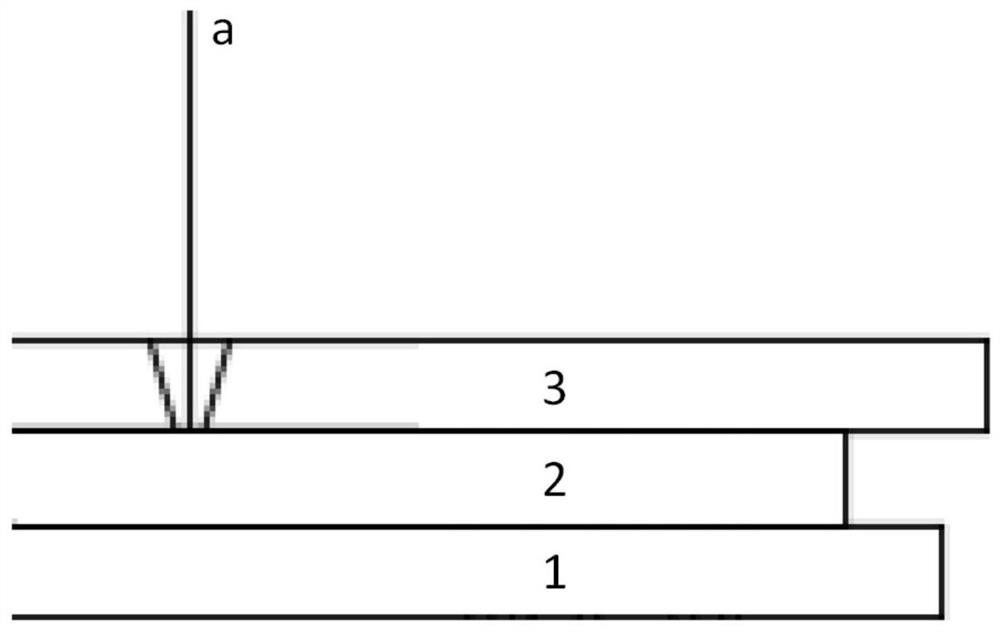

[0039] (2) Die-cutting waste disposal: such as figure 1 , Die-cut the primary material belt in a die-cutting machine, and discharge a punching waste to form a secondary material belt; such as figure 2 , a die-cutting machine is provided with a knife line a that matches a die-cutting pattern, such as image 3 , the punching level of knife line a is acetate cloth 3. Cut line a includes cut lines a connected in sequence 1 , knife line a 2 and knife line a 3 , knife line a 2 At an angle of 30° to the running direction of the material belt. knife line a 1 and knife l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com