Dual power contact drive mechanism

A driving mechanism and dual power supply technology, applied in the contact driving mechanism, emergency power supply arrangement, circuit and other directions, can solve the problems of shortening the service life of the switch, the speed is not fast enough, and the contacts are easily burnt out, so as to prolong the service life and avoid the burnout effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be described in detail below in conjunction with the embodiments and the accompanying drawings. It should be noted that the described embodiments are only intended to facilitate the understanding of the present invention, rather than limiting it in any way.

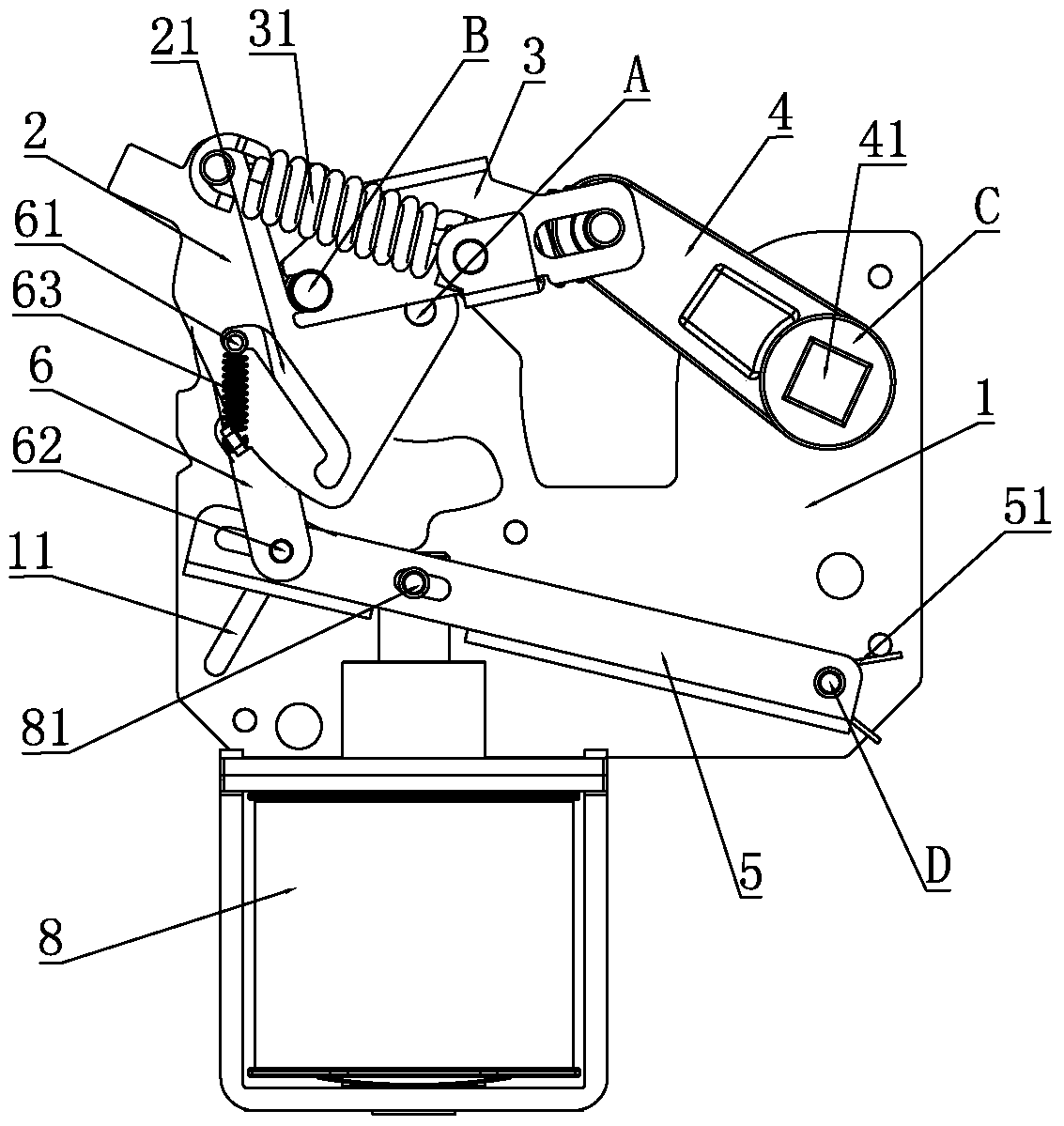

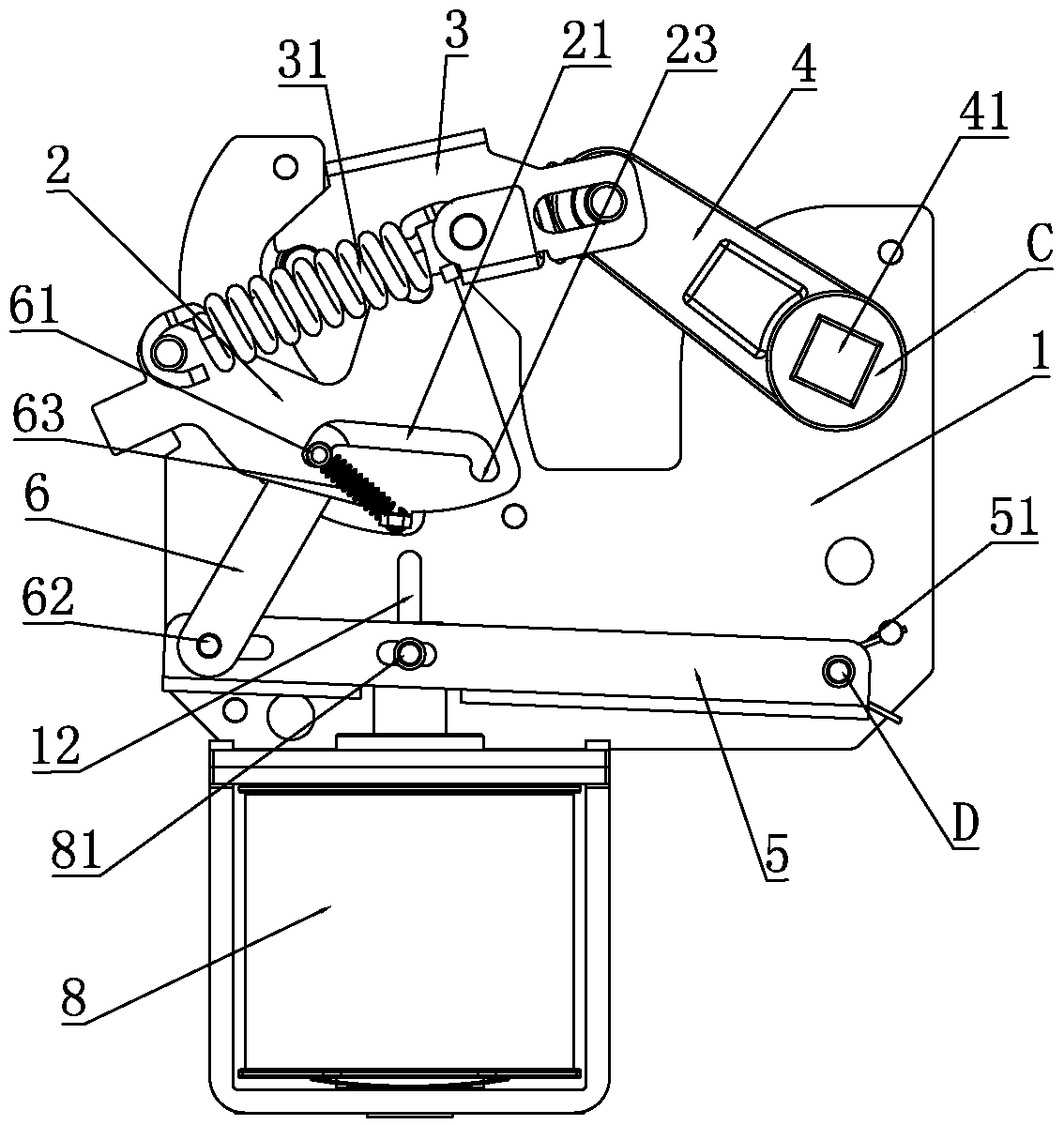

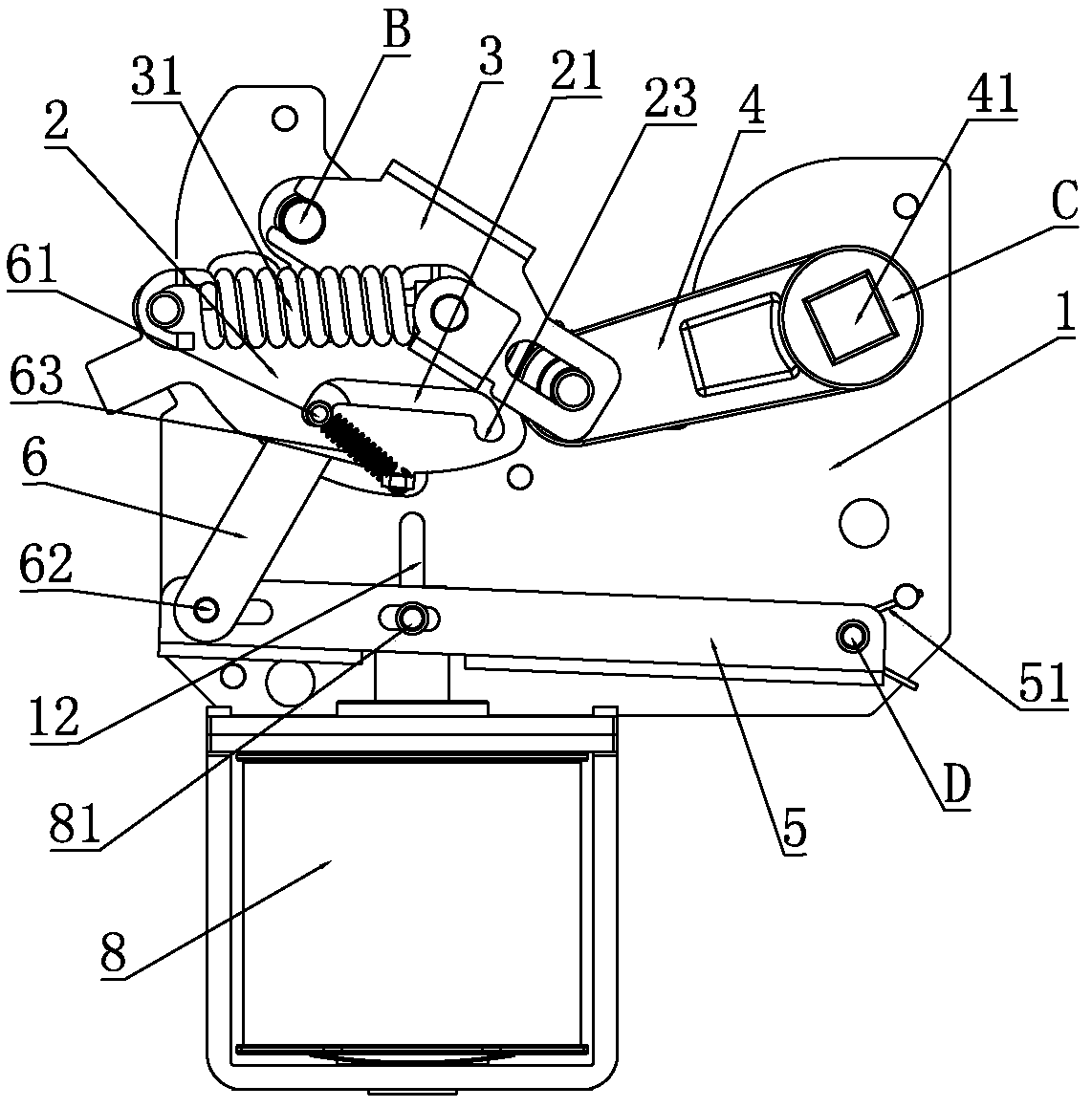

[0035] see figure 1 and Figure 7 As shown, a dual power contact driving mechanism provided in this embodiment has a structure including a fixed plate 1, a rotating shaft A of the movable frame 2, a rotating shaft B of the driving frame 3, a rotating shaft C of the moving contact frame 4 and a movable The rotation axes D of the rods 5 are all mounted on the fixed plate 1 . Also offer the first guide hole 11 and the second guide hole 12 on the fixed plate 1, the connecting rod 62 that slidably connects the left end of the movable rod 5 and the lower end of the connecting rod 6 is inserted in the first guide hole 11 and can be slid, slidably connected. The middle part of movable rod 5 and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com