Panel feeding device

A material guiding device and material pressing device technology, which is applied in the directions of transportation and packaging, conveyor objects, conveyors, etc., can solve the problems of loose pressing material, low production efficiency, large error, etc., and achieve enhanced stability and stable transportation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

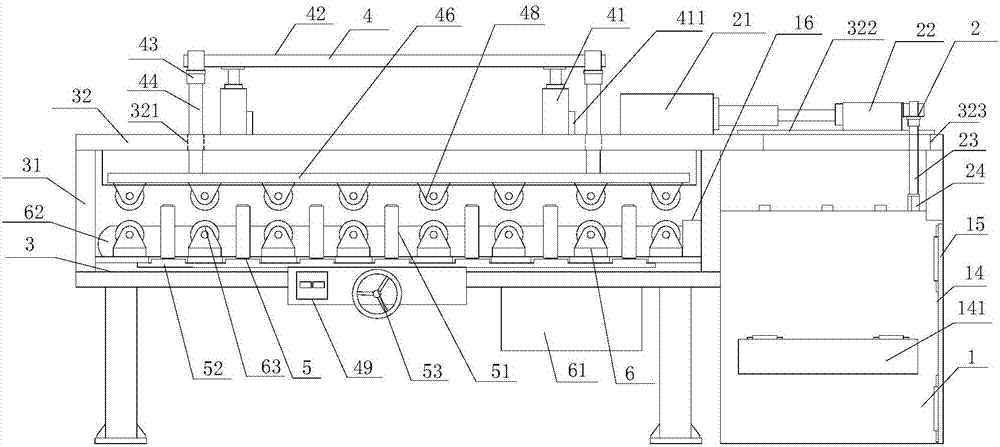

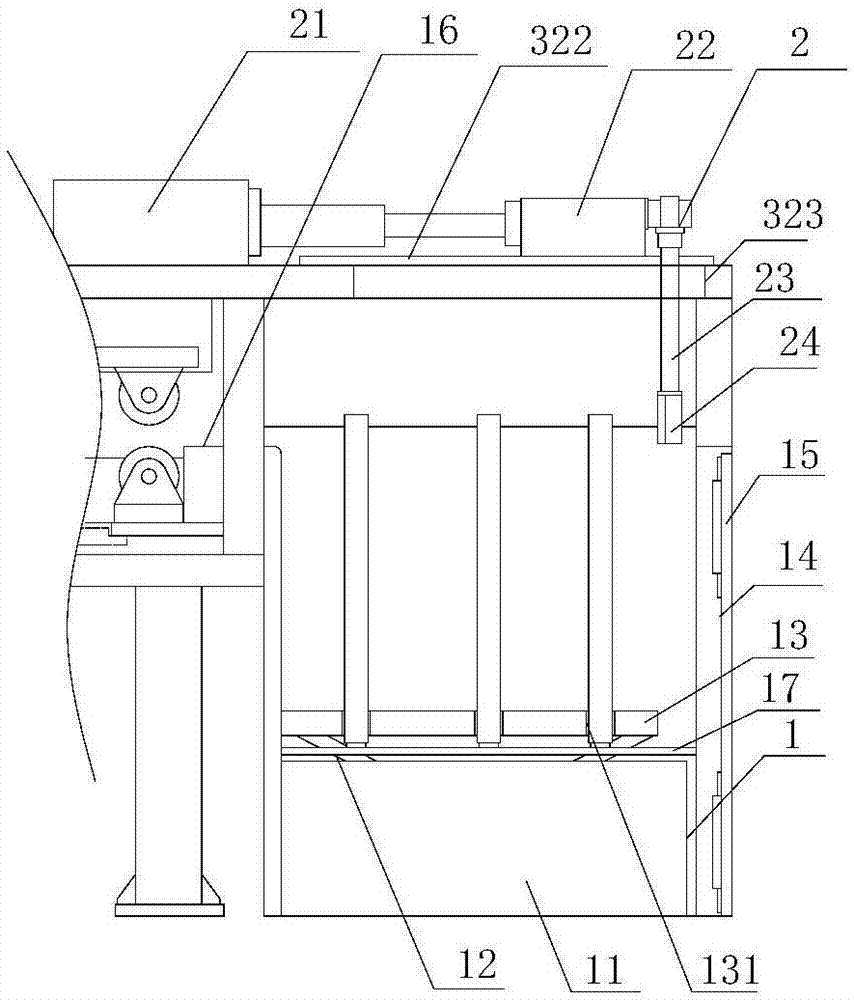

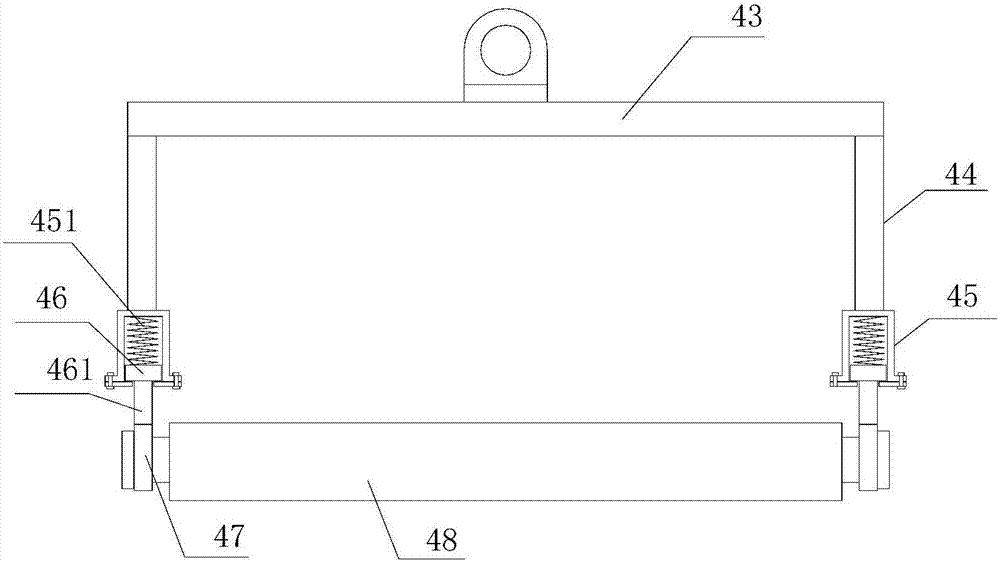

[0022] refer to Figure 1 to Figure 4 A plate feeding device of the present invention comprises a lifting and splitting device 1, a material pushing device 2, a frame 3, a pressing device 4, a material guiding device 5 and a conveying device 6, and the lifting and splitting device 1 is provided with a lift Mechanism 12, described elevating mechanism 12 is provided with material placement platform 13, and one side of described lifting slice device 1 is provided with frame 3, and conveying device 6 is installed on described frame 3, on described conveying device 6 Several conveying roller assemblies 63 are provided, the frame 3 is also provided with a mounting frame 32, the mounting frame 32 is provided with a pressing device 4, and the pressing device 4 is provided with a link bracket 44, so The connecting rod bracket 44 runs through the installation cavity 321 on the mounting frame 32, and the below of the connecting rod bracket 44 is provided with a mounting frame 45, and a p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com