Cloth cutting-off device for textiles

A cutting and fabric technology, applied in the cutting of textile materials, textiles and papermaking, etc., can solve the problems of uneven cutting of fabrics, increased waste rate of textile enterprises, and push up production costs of textile enterprises, so as to improve the use stability, The effect of avoiding manual cutting and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Embodiment of the present invention is described below in conjunction with accompanying drawing, embodiment does not constitute limitation of the present invention;

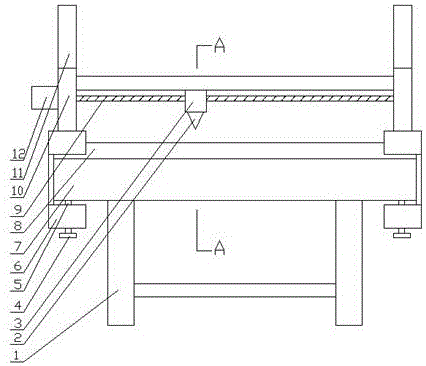

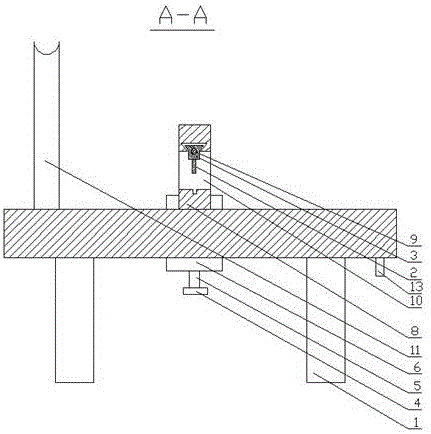

[0022] Such as figure 1 , figure 2 As shown, the cloth cutting device for weaving has a structure including a workbench 7, which is a cuboid structure. When in use, the workbench 7 is used to support components such as the frame 10 and provide sliding support to the chute 6; There are chute 6 on both sides of the table 7. The chute 6 is a U-shaped structure. The chute 6 half-wraps the side of the workbench 7. When in use, the chute 6 can slide along the workbench 7 to adjust the distance between the cutter 2 and work. The distance from the edge of the platform 7 is suitable for different workers to operate the device; the upper surface of the chute 6 is provided with a frame 10, which is used to slide and support the slider 3 during use.

[0023] In the above embodiment, specifically, the frame 10 is hu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com