Non-tillage precision seeder

A seeder, precision technology, applied in the field of agricultural machinery, can solve the problems of reducing the emergence rate, not being able to cut well, unreasonable design, etc., and achieve the effects of preventing soil erosion, improving soil structure, and increasing organic matter

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The detailed description and technical content of the present invention are described below with the accompanying drawings, but the accompanying drawings are only provided for reference and description, and are not intended to limit the present invention.

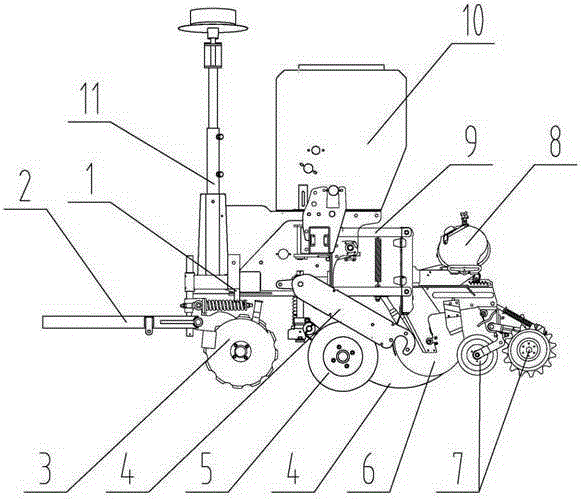

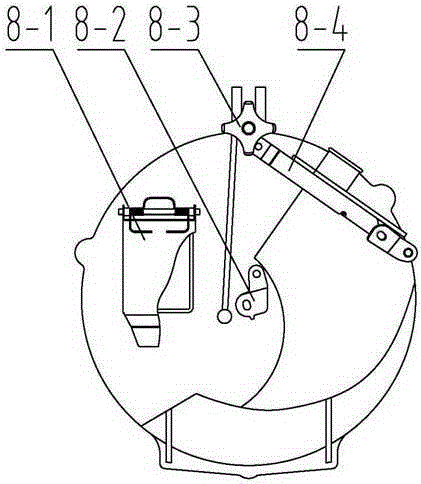

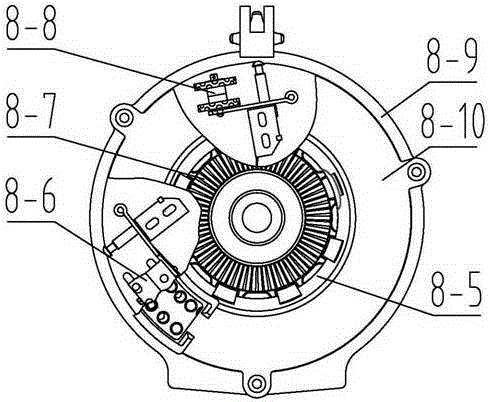

[0019] According to attached Figure 1-4 , no-tillage precision seeder, mainly including frame 1, traction frame 2, ditching and fertilizing mechanism 3, power transmission mechanism 4, no-tillage stubble removal mechanism 5, sowing unit 6, soil suppression mechanism 7, seed metering device 8, The profiling mechanism 9, the seed fertilizer box 10, and the track marker 11 are characterized in that two track markers 11 are installed on both sides of the front of the frame 1; the traction frame 2 is connected to the frame 1 in a split and detachable manner The front side; the power transmission mechanism 4 is connected to the rear side of the frame 1 and is connected with the fertilizer box fertilizer discharge mechanis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com