Seed cleaning device for scraping airflow seeder

A seeder and air flow type technology is applied in the field of seed cleaning devices of scraping and touching air flow seeders, which can solve the problems that the seed cleaning effect cannot reach the precise seeding effect of the seed metering device, and the effect of the seed cleaning effect is large, and the seed cleaning effect can be achieved. The effect is good, and the effect of increasing the pass rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

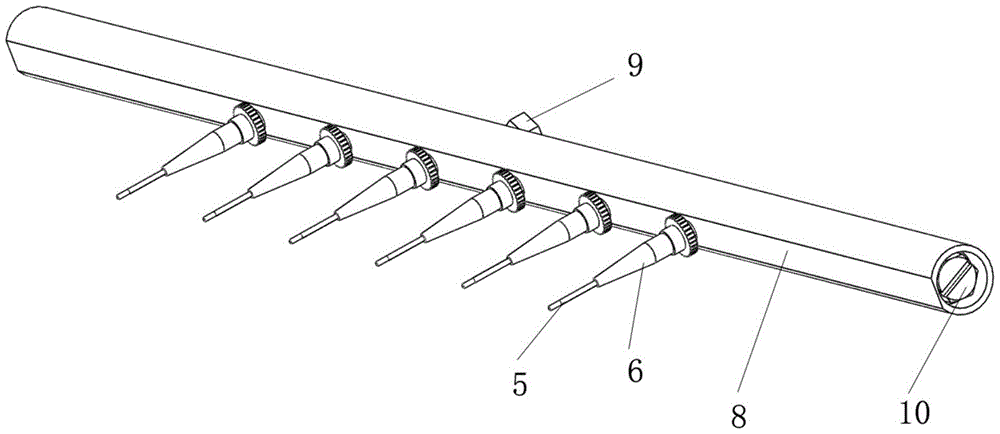

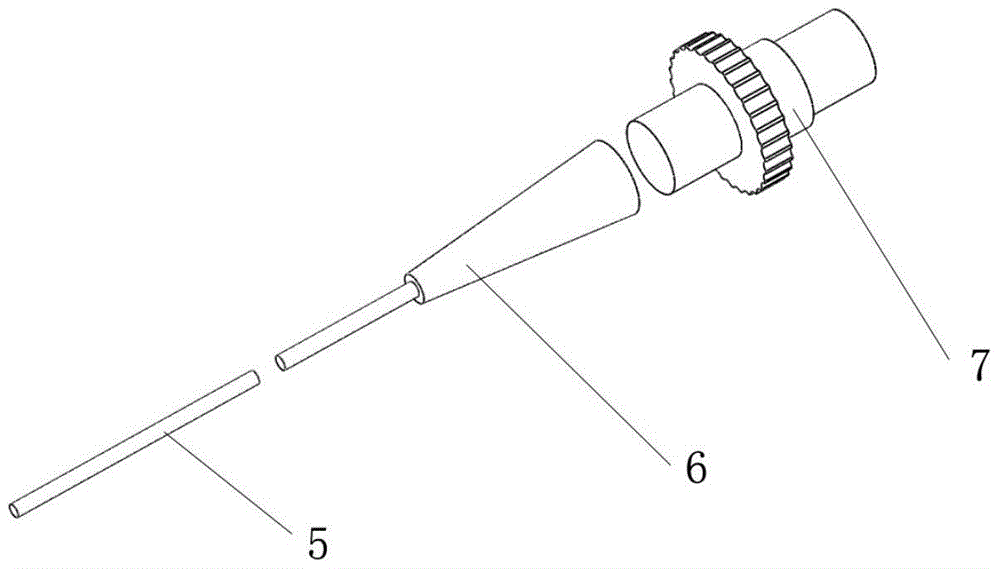

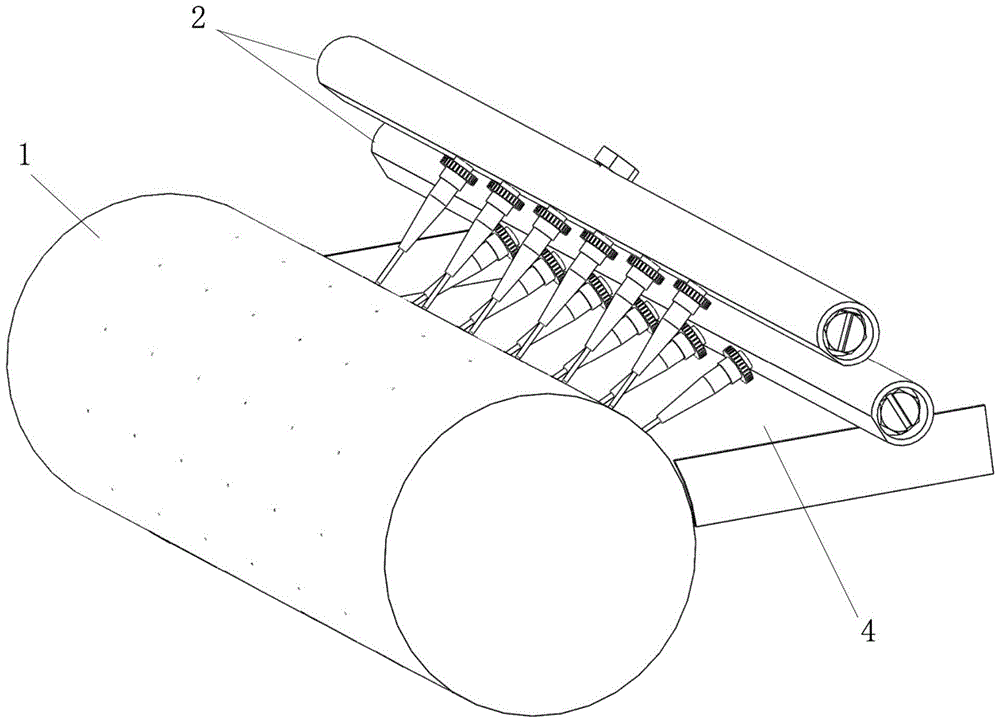

[0025] In this embodiment, a kind of clearing device of a scraping airflow type seeder, such as image 3 As shown, it is arranged on the drum body 1 of the seed metering device, and the seed clearing device includes at least one set of seed clearing pipes 2, and the seed clearing pipes are externally connected to the air supply system; figure 1 As shown, the seed cleaning tube includes a seed cleaning tube body 8, an air needle 6, a threaded needle tip 7, a seed setting needle 5 and a quick-plug connector 9. On the cylindrical surface of the seed cleaning tube body, there are multiple threaded rotary needles distributed on one side , the other side is equipped with a quick-plug connector, and each threaded needle is equipped with an air needle and a dialing needle. The threaded needle, air needle and seeding needle are connected in sequence, and the quick-plug connector is externally connected to the air supply system. The air supply system is mainly composed of air pipe and p...

Embodiment 2

[0029] The seed cleaning device of a kind of scraping airflow type seeder of this embodiment, compares with embodiment 1, and its difference is: as image 3 or Figure 4 As shown, the seed clearing device includes two sets of seed clearing tubes, which are the first seed clearing tube and the second seed clearing tube respectively. Arranged on the drum body, the bottom ends of all the dial needles on each seed cleaning tube are located on the same generatrix of the drum body, such as Figure 5 As shown, the bottom ends of the two rows of dial needles corresponding to two adjacent seed cleaning tubes are respectively located on two different busbars of the drum body, and the arc length L1 between the two busbars is 5 to 12mm, to avoid two air The air flow of the needles interacts, and the two needles act on the seed group on the seed suction hole 11 at the same time, squeezing the seeds so that the seeds on the seed suction hole are completely emptied, increasing the empty see...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com