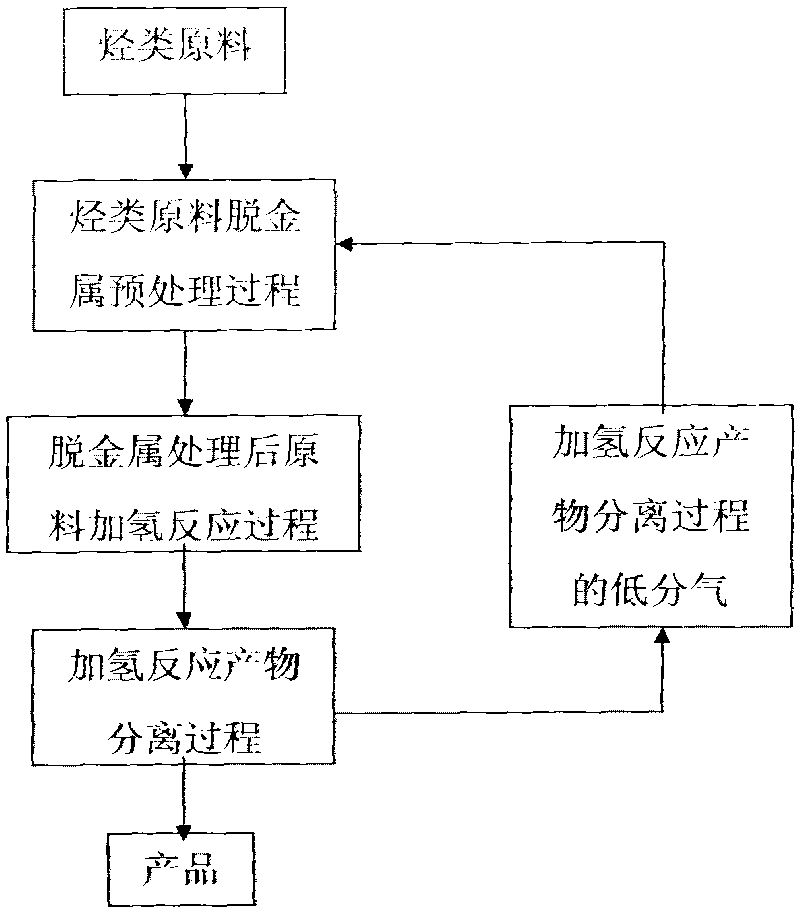

Method for hydrogenating hydrocarbon material containing metal impurity

A technology for metal impurities and hydrocarbons, which is applied in the field of hydrotreating of hydrocarbon materials containing metal impurities, can solve the problems of improved de-ironization effect, increased bed pressure drop, too fast catalyst bed pressure drop, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

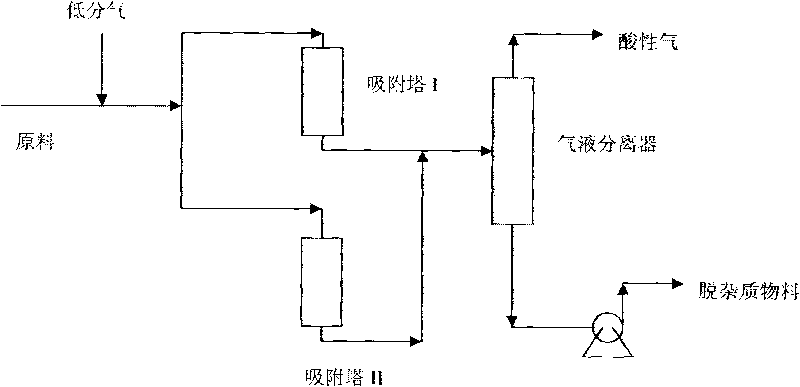

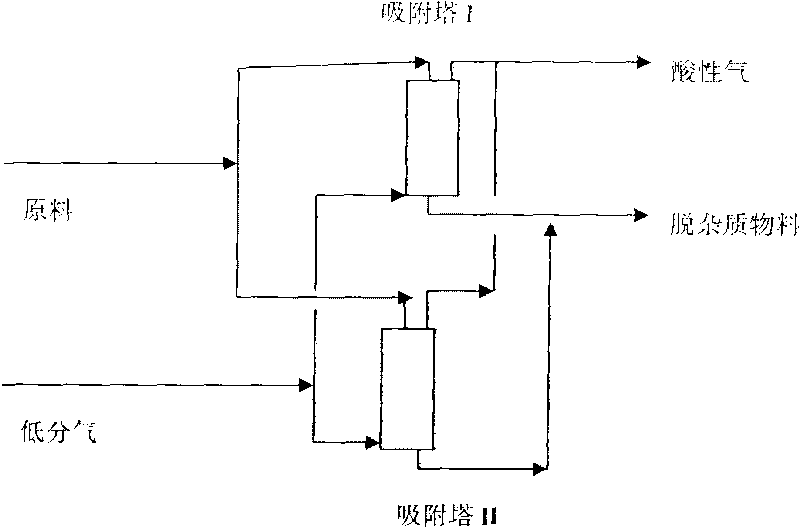

Method used

Image

Examples

Embodiment 1

[0025] Gasoline fraction hydrorefining process.

[0026] During the processing process, the raw material of the FCC gasoline fraction was contaminated by iron impurities, and the content of iron element was 32μg / g. The catalyst for the hydrorefining process is the FDS-4A catalyst developed by Fushun Petrochemical Research Institute and produced by Wenzhou Huahua Group Company. The operating conditions are the average reaction temperature of 260°C, the reaction pressure of 4MPa, and the volumetric space velocity of 6h. -1 , The volume ratio of hydrogen to oil is 400:1. The low pressure separator flash vapor (low gas separation), the volume content of hydrogen sulfide is 3.4%, and the pressure is 0.7MPa. The experimental schemes 1-1 and 1-2 for the removal of metal impurities use a catalyst. The catalyst is the residual oil hydrogenation protective agent FZC-102 (Raschig ring shape, diameter 5mm) developed and produced by Fushun Petrochemical Research Institute. Embodiments 1-3 ad...

Embodiment 2

[0030] Hydrorefining process of diesel oil fraction.

[0031] The iron-containing impurities in the diesel oil fraction and the contamination during processing are 85μg / g in terms of iron. The catalyst for the hydrorefining process is FH-98 catalyst developed by Fushun Petrochemical Research Institute and produced by Wenzhou Huahua Group Company. The operating conditions are the average reaction temperature of 320℃, the reaction pressure of 6MPa, and the volumetric space velocity of 2h. -1 , The volume ratio of hydrogen to oil is 800:1. The low-pressure separator flash vapor (low-separated gas) has a volume content of 6.5% and a pressure of 1.0 MPa. The catalyst for removing metal impurities uses the residue hydrogenation protective agent FZC-101 (seven-hole ring, outer diameter 16mm) developed and produced by Fushun Petrochemical Research Institute, FZC-102 (Raschig ring, diameter 5mm), the volume ratio is 1:2 , Stratified filling, the diesel raw material is first contacted wit...

Embodiment 3

[0035] Vacuum distillate (distillation range 379~540℃) hydrotreating process.

[0036] The content of various impurities is 12μg / g iron, 25μg / g calcium and 22μg / g sodium. The catalyst for the hydrotreating process is 3936 catalyst developed by Fushun Petrochemical Research Institute and produced by Fushun Petrochemical Company Catalyst Plant. The operating conditions are the average reaction temperature of 370℃, the reaction pressure of 10MPa, and the volumetric space velocity of 1h. -1 , The volume ratio of hydrogen to oil is 1500:1. The volume content of hydrogen sulfide in the flash steam (low gas separation) of the low-pressure separator is 5.1%, and the pressure is 1.5 MPa. The catalyst for removing metal impurities uses the residue hydrogenation protective agent FZC-100 (seven-hole ball, outer diameter 16mm), FZC-101 (seven-hole ring, 16mm outer diameter), FZC-102 (pull-out) developed and produced by Fushun Petrochemical Research Institute. West ring, diameter 5mm), volume...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com