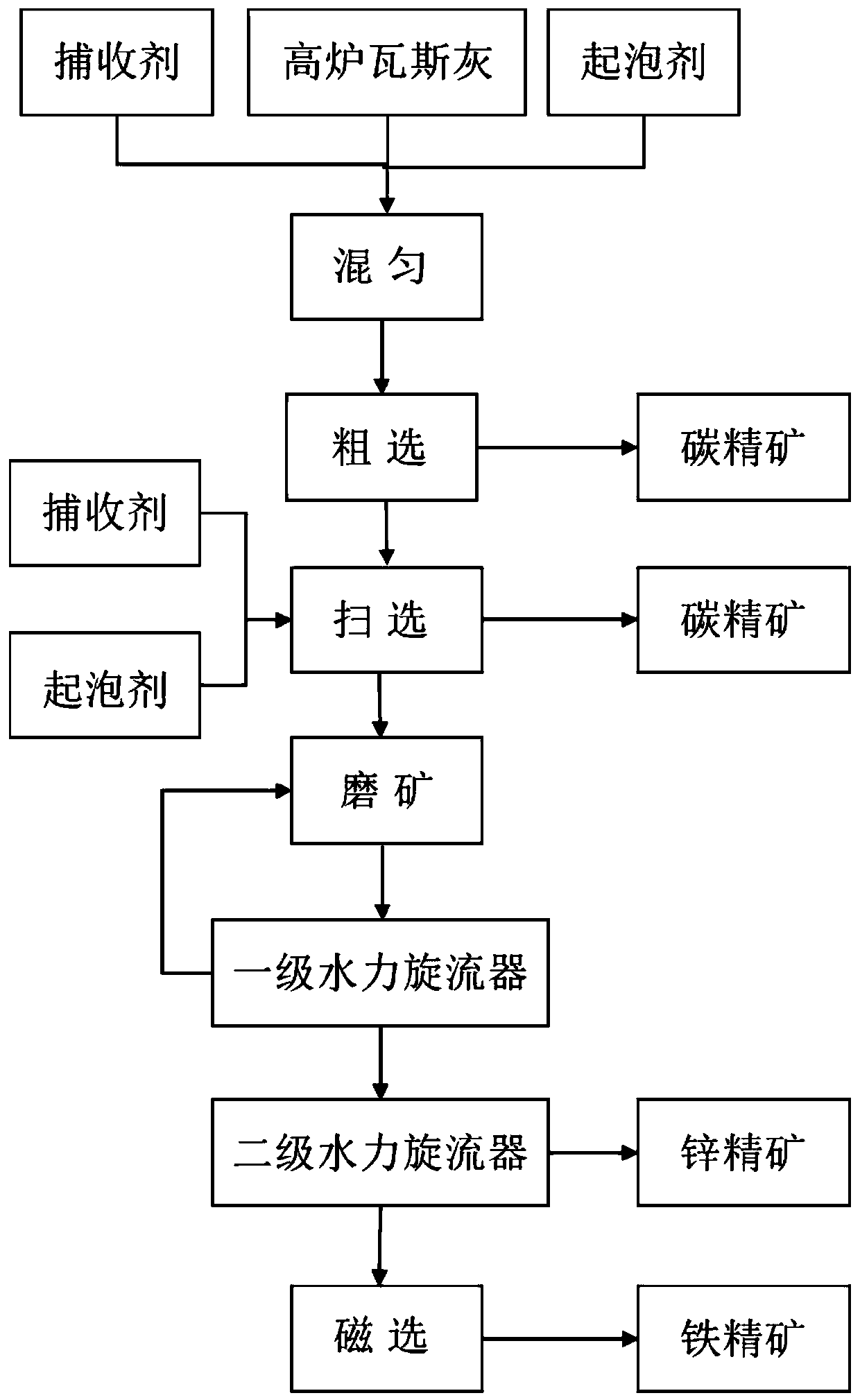

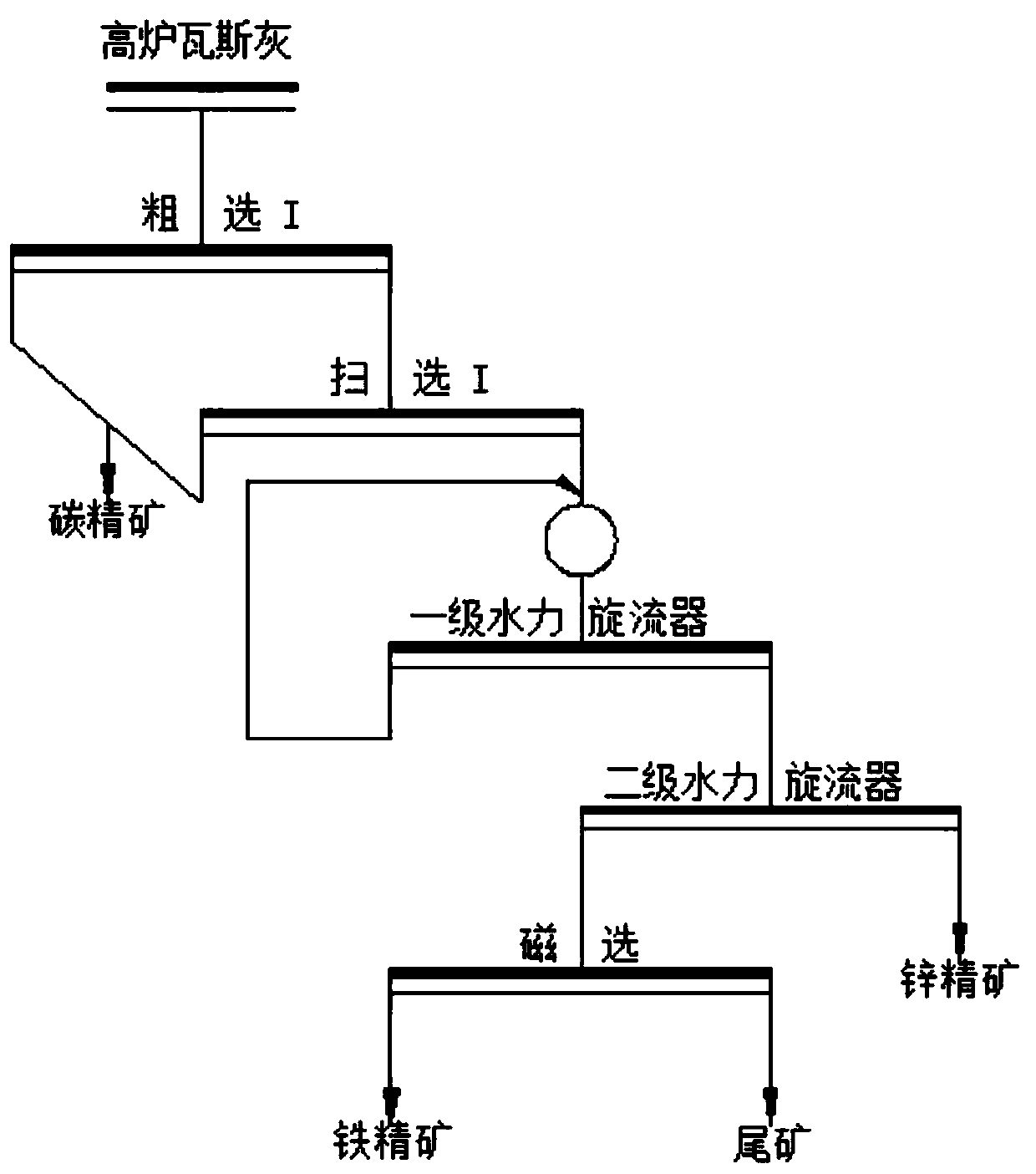

Method for recovering carbon, iron and zinc from blast furnace gas dust

A technology for recovering carbon from blast furnace gas ash is applied in the field of recovering carbon, iron and zinc from blast furnace gas ash. low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 3

[0057] Example 3 A blast furnace gas ash from an ironworks in Yunnan was selected. The grade of TFe in the blast furnace gas ash was 30.15%, the grade of Zn was 6.54%, and the grade of C was 20.10%. The analysis of the main components is shown in Table 2.

[0058] Table 2

[0059] element TF CaO MgO SiO 2

Embodiment 1

[0061] (1) the blast furnace gas ash is modulated into a concentration of 35% by weight ore slurry in a mixing tank, and mixed with diesel oil and terpineol oil, the amount of diesel oil is 600g / t, and the amount of terpineol oil is 100g / t;

[0062] (2) roughing the mixed ore slurry obtained in step (1) to obtain the first carbon concentrate and roughing tailings;

[0063] (3) Add diesel oil and terpineol oil to step (2) gained roughing tailings, the amount of diesel oil is 200g / t, and the amount of terpineol oil is 25g / t; Mix and then sweep to obtain the second carbon concentrate and scavenging tailings;

[0064] (4) Grinding the scavenging tailings with a particle size of 67.86% by weight less than 0.074mm obtained in step (3) in a tower mill, and then feeding into a primary hydrocyclone (100mm in diameter) for classification, And control the primary classification particle size to 0.038mm and the ore feeding pressure to 0.2MPa to obtain primary grit with a particle size gr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com