Electric-control mechanical stepless row spacing regulator for seeder

A technology of planter and regulator, applied in the directions of planter parts, applications, fertilization devices, etc., can solve the problems of inability to adapt to the national conditions of small plot farming, inability to achieve plant spacing, stepless adjustment, etc., to eliminate the phenomenon of oscillation, structure Simple and efficient results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

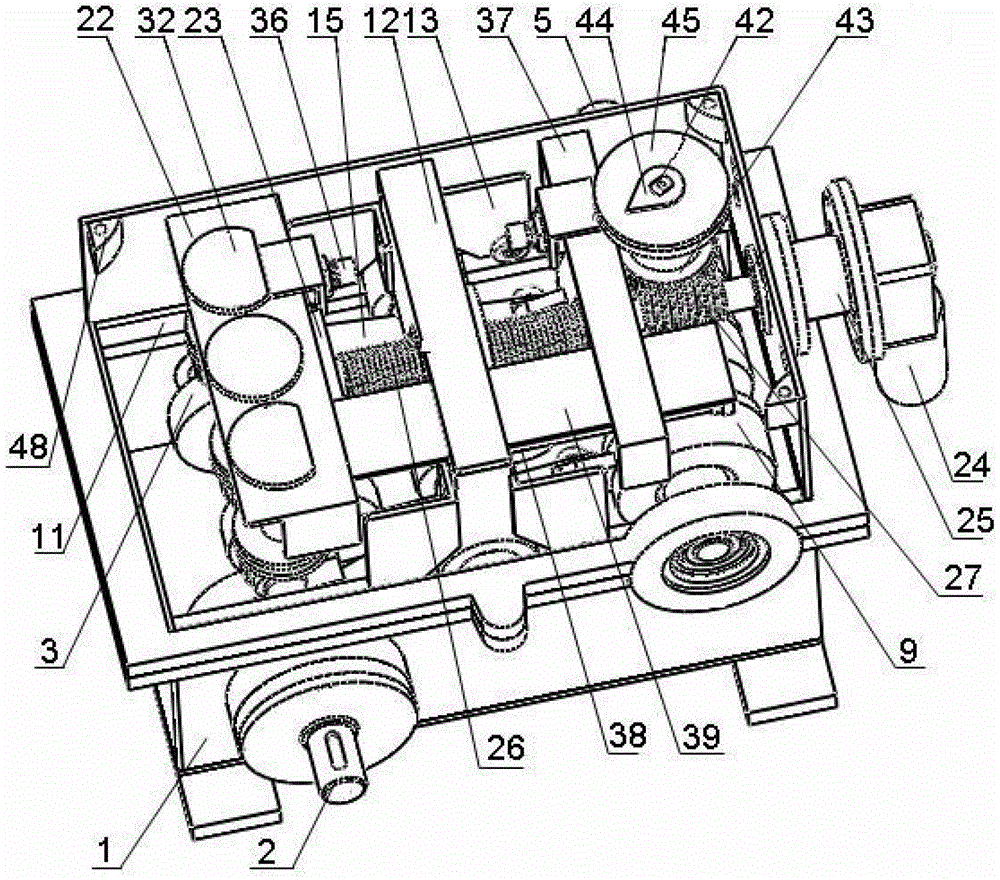

[0032] exist Figure 1-8 In the example shown:

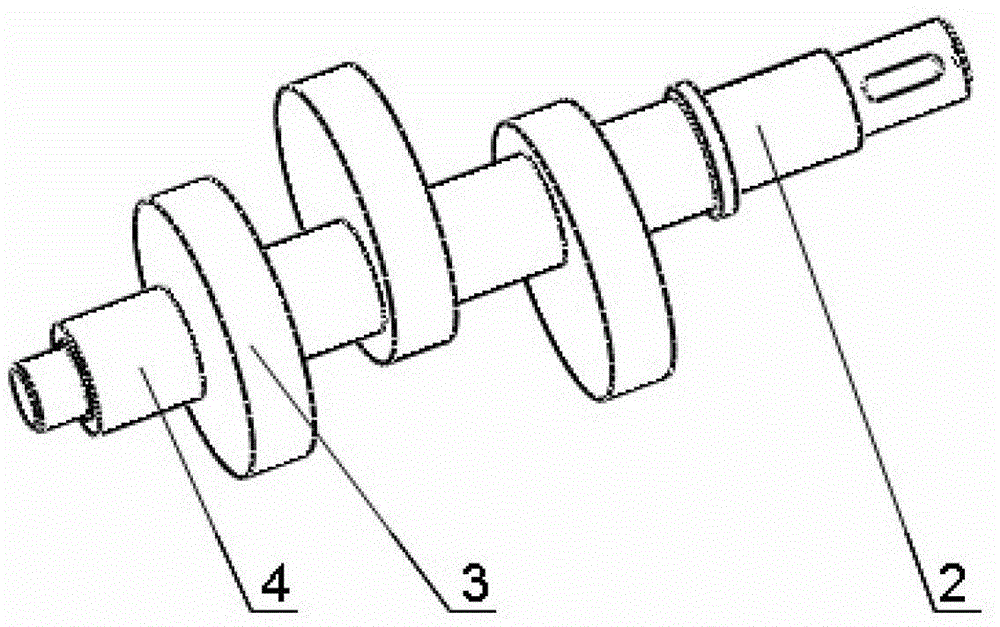

[0033] The power input device is installed in the lower part of the box body 1, including the input shaft 2 supported horizontally on the box body 1 via bearings, three cams 3 fixed on the input shaft 2 and the spacer sleeve I4 installed between the cams 3 at intervals , where three cams 3 are fixed on the input shaft 2 at 120°.

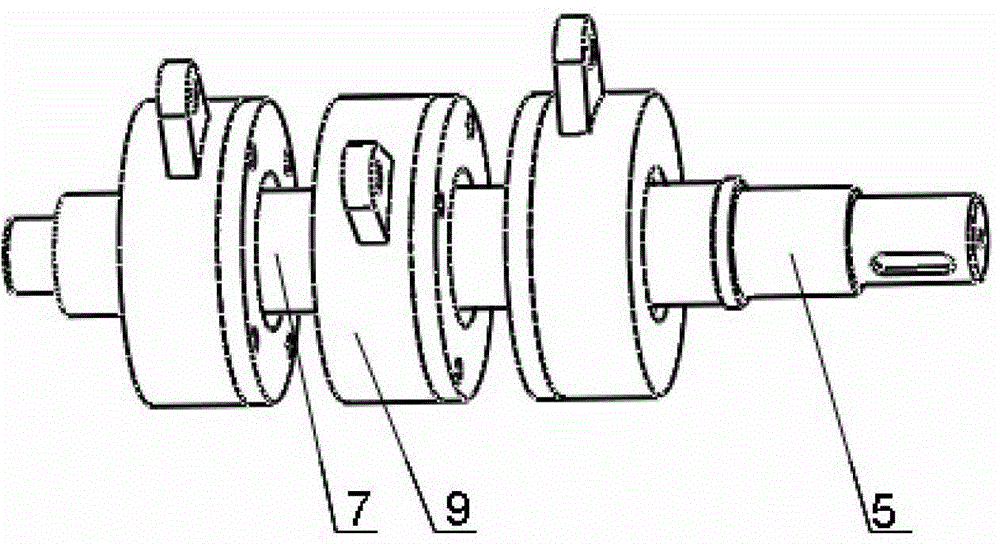

[0034] The power output device is installed on the upper part of the box body 1, including the output shaft 5 supported horizontally on the box body 1 via bearings, three overrunning clutches 6 and four spacer sleeves II7, of which the three overrunning clutches 6 are all fixed on the output shaft 5, the interval between adjacent overrunning clutches 6 is spacer II 7; corresponding to each overrunning clutch 6, a clutch end cover 8 and a clutch housing hub 9 are provided, and the overrunning clutch 6 is located between the clutch end cover 8 and the clutch housing hub 9 In the cavity formed by dockin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com