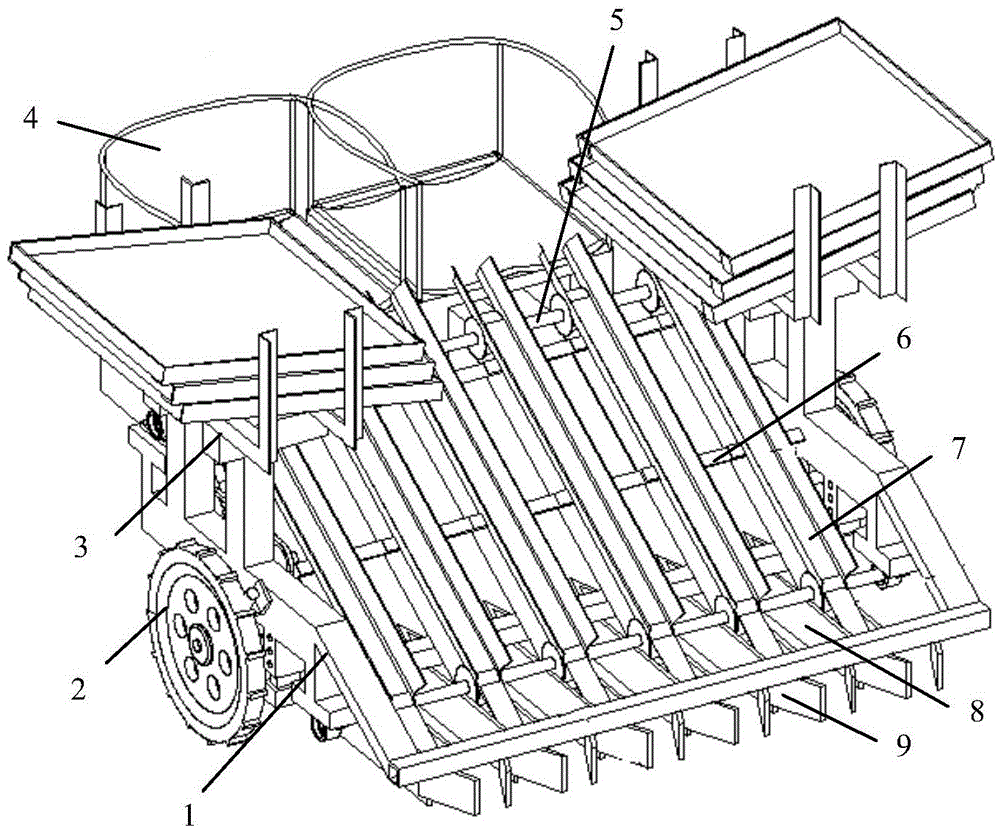

Semi-automatic garlic seeder

A kind of seeder and semi-automatic technology, applied in the direction of sowing seeder, seeder parts, fertilization device, etc., can solve the problems of low production efficiency, affecting farmers' production enthusiasm, and increasing labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

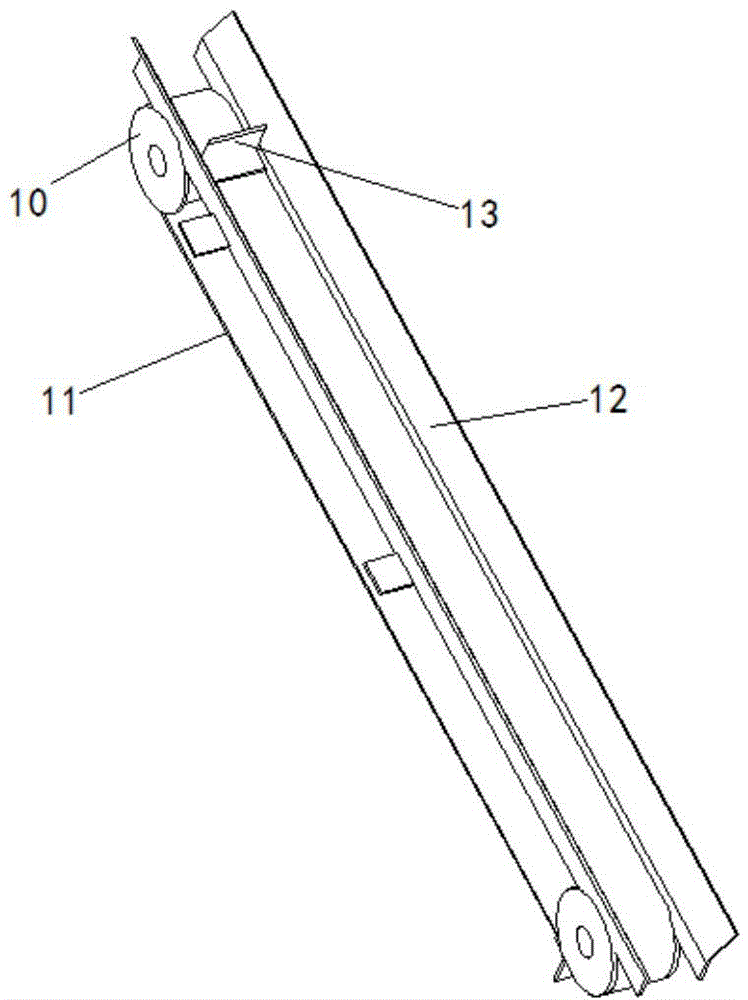

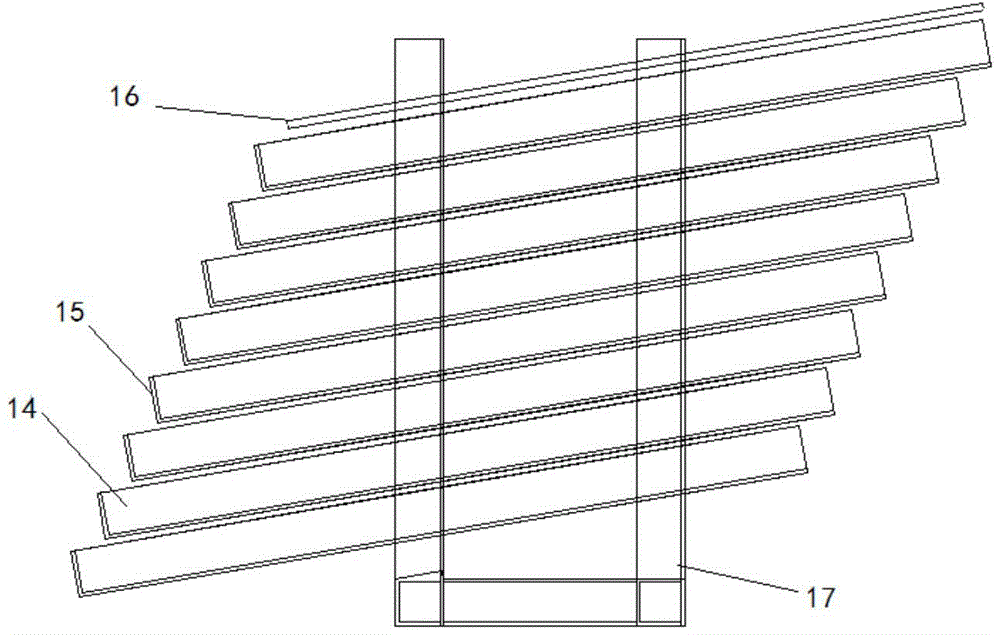

[0019] A semi-automatic garlic seeder, the pulley shaft of the garlic seed box delivery mechanism is installed on the frame through the bearing seat, the timing pulley key is installed on the pulley shaft, and the upper and lower timing pulleys are connected by the timing belt. Inclined installation; the baffle of the garlic box support mechanism is installed on the support frame, the baffles on both sides of the timing belt are installed in parallel, and the upper end of the baffle is inclined to the outside, so that the baffle has a V-shaped opening, which is convenient for the staff to put in the garlic box; The wing plates on both sides of the trencher are slightly inclined outward to prevent the soil from falling into the seed ditch. There is a guide plate in the middle of the wing plates on both sides. The inclination angle of the guide plate relative to the ground is the same as that of the synchronous belt and the ground. The upper surface of the garlic box is in the sa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com